How to Choose the Best Label Counter Machine for Your Business

12th Jun 2025

In today’s fast-paced business environment, efficiency is key, especially when it comes to managing inventory and ensuring product labeling is accurate. Whether you run a warehouse, a manufacturing plant, or a retail operation, having a reliable label counter machine can make a significant difference. These machines are designed to streamline the process of counting and applying labels, saving time and reducing human error.

For businesses handling large volumes of labels—be it for packaging, shipping, or inventory management—choosing the right label counter machine is crucial. With so many options on the market, it’s easy to feel overwhelmed by the choices available. This blog aims to simplify that decision-making process, guiding you through the factors you should consider to select the best label counter machine for your specific needs. From speed and accuracy to label compatibility, we’ll cover everything you need to know to maximize efficiency in your operations.

By the end of this blog, you’ll have a clearer understanding of how to select the ideal label counter machine to enhance your business's productivity and ensure a smooth and error-free labeling process.

Types of Label Counter Machines

Label counter machines come in a variety of types, each designed to meet different business needs. Understanding the key features of each type can help you choose the one that best fits your operational requirements.

1. Manual Label Counter Machines

Manual label counter machines are the most basic type, requiring the operator to load labels and manually control the counting process. These machines are typically more affordable but may not be as efficient for businesses with large volumes of labels. While they are easy to use and require minimal maintenance, manual label counters can be slow and prone to human error.

2. Semi-Automatic Label Counter Machines

Semi-automatic label counter machines offer a balance between efficiency and cost. They automate some parts of the process, such as feeding labels through the machine, while still requiring the operator to control certain functions like stopping or starting the counting cycle. These machines are ideal for businesses that need a more reliable solution than manual counters but don’t require full automation.

3. Fully Automatic Label Counter Machines

Fully automatic label counter machines offer the highest level of efficiency. These machines can count, rewind, and stack labels without requiring much operator involvement. They are designed for high-volume operations where speed, accuracy, and consistency are critical. Automatic machines can handle a variety of label sizes and types, including opaque and transparent labels, making them versatile for a wide range of industries.

4. Specialized Label Counter Machines

Some label counter machines are designed for specific applications. For example, machines designed to count transparent or opaque labels, such as the Labelmate RRC 400 U Large Form Reel-to-Reel Label Counter, are ideal for businesses that need to handle unique labeling requirements. These machines are equipped with features that allow them to process different materials effectively.

Understanding the different types of label counter machines will help you narrow down your options based on your business needs.

Key Features to Look for in a Label Counter Machine

When choosing a label counter machine for your business, several features should be taken into consideration to ensure you get the best value for your investment. Here are some of the most important features to look for:

1. Speed and Efficiency

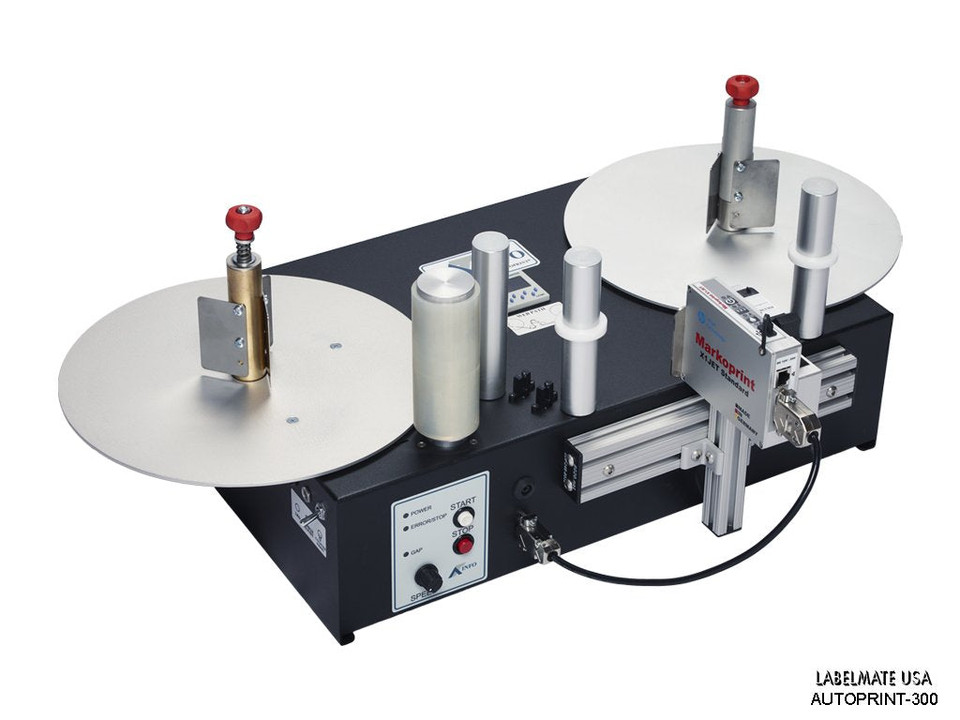

The speed at which a label counter operates is crucial for businesses that handle high volumes of labels. Look for machines that can count and rewind labels at a fast rate without compromising accuracy. For high-speed operations, machines like the Labelmate Autoprint 300 Reel-to-Reel High-Speed Counter can help increase your productivity, saving you valuable time during the counting process.

2. Accuracy and Precision

Accuracy is paramount when dealing with inventory and labeling. A machine that counts labels inaccurately can result in discrepancies, wasted materials, or delays. Look for machines with high-resolution sensors and consistent performance. Some machines also have a built-in calibration system to ensure optimal counting accuracy every time.

3. Capacity and Label Size Compatibility

The capacity of the label counter machine and the size of labels it can handle are important factors in determining its suitability for your business. A machine with a higher label capacity can save time by processing larger batches at once. Additionally, consider the range of label sizes it can accommodate. Some businesses may need to count a variety of label sizes, so ensure the machine offers versatility. For instance, models like the Labelmate RRC 400 U are capable of handling large and unique label formats.

4. Ease of Use and Setup

A user-friendly interface is essential, especially if you have multiple staff members using the machine. Look for models with intuitive controls and clear instructions. Some machines offer digital interfaces, making them easier to operate and configure. Ease of setup and operation reduces training time and allows staff to focus on their tasks rather than troubleshooting the equipment.

5. Durability and Build Quality

A robust and durable label counter machine is a long-term investment. Choose machines that are made from high-quality materials, which can withstand continuous use and harsh environments. Models with industrial-grade components are designed to last longer and maintain consistent performance over time, even under demanding conditions.

6. Maintenance and Support

Consider the maintenance requirements and after-sales support offered by the manufacturer. A label counter machine should be easy to maintain, with accessible parts and clear instructions for routine upkeep. Additionally, having a reliable technical support team can ensure your machine stays operational and any issues are quickly resolved. You can explore technical support options for machines like the Autoprint 300, which is known for its high-speed performance and support services.

Benefits of Investing in a Label Counter Machine

Investing in a label counter machine can provide numerous benefits for businesses, especially those that rely on accurate and efficient labeling processes. Here are some key advantages:

1. Improved Efficiency and Productivity

Label counting by hand can be time-consuming and prone to errors. A label counter machine automates this process, dramatically increasing speed and accuracy. With a high-speed machine, your team can handle larger volumes of labels in a shorter amount of time, allowing them to focus on other tasks and boosting overall productivity.

2. Reduced Human Error

Manual counting can lead to human errors, such as counting the wrong number of labels or misplacing batches. This can result in inventory discrepancies, delays, and additional costs. By using a label counter machine, businesses can minimize these risks and ensure each batch of labels is counted correctly, contributing to smoother operations.

3. Cost Savings

Although the initial investment in a label counter machine may seem significant, the long-term cost savings are undeniable. By streamlining the counting process, businesses reduce labor costs and minimize material waste. Additionally, the increased accuracy provided by these machines can prevent costly mistakes such as over- or under-ordering labels, helping to optimize inventory management.

4. Versatility for Different Label Types

Label counter machines are designed to handle various types of labels, including thermal transfer labels, which are commonly used in barcode printing. If your business deals with multiple types of labels, having a machine that can handle them all efficiently will help avoid the need for multiple devices. For example, businesses can look for models that support both custom thermal transfer labels and general-purpose label types.

5. Scalability for Growing Businesses

As your business grows, the volume of labels you need to process will likely increase. Investing in a label counter machine ensures that your business can scale operations without sacrificing efficiency. Machines like the Labelmate RRC 400 U are ideal for businesses looking to handle larger and more diverse batches of labels as they expand.

How to Integrate a Label Counter Machine into Your Workflow

Once you've selected the right label counter machine, the next step is integrating it smoothly into your workflow. This ensures that the machine contributes effectively to your business operations. Here are some best practices to consider:

1. Assess Your Labeling Process

Before implementing the label counter machine, assess your current labeling process to understand where the machine can be most beneficial. Whether you’re manually counting labels or relying on a less efficient machine, a counter machine can reduce time spent on repetitive tasks. Position the label counter in a location where it complements other processes like label printing and packaging.

2. Train Your Team

While many label counter machines are designed to be easy to use, providing your team with proper training will ensure the equipment is used to its full potential. This includes understanding how to load and unload labels, how to adjust settings for different label sizes and types, and how to maintain the machine. Some suppliers, such as Autoprint, offer technical support, so if you need assistance, you can rely on expert guidance.

3. Automate with Software

Integrating the label counter machine with other parts of your business management system, such as inventory or shipping software, can help automate your labeling process. By linking the machine to a system that tracks inventory, you can instantly update stock levels or track label usage in real-time, streamlining your operations even further.

4. Regular Maintenance

To keep the label counter machine in top condition, implement a regular maintenance schedule. This may include cleaning the machine, checking for wear and tear, and recalibrating if necessary. Routine maintenance can help prevent issues like label misfeeds, which could result in downtime or inaccurate counts.

5. Maximize Efficiency with High-Yield Labels

Using high-quality labels and purchasing custom thermal transfer labels in bulk can further improve the efficiency of your label counter machine. For example, high-yield ink cartridges, such as those available in the Epson T01D120 High Yield Ink, ensure that you get more out of your printing materials, reducing the frequency of replacements.

Maximizing Efficiency with the Right Label Counter Machine

In conclusion, selecting the right label counter machine for your business is a strategic investment that can significantly improve your inventory management and operational efficiency. Whether you need a label counter machine for sale or want to buy a label counter machine online, it's essential to choose one that suits your specific needs, from label type to speed and accuracy.

Incorporating the right equipment into your workflow, training your team, and ensuring proper maintenance will not only save you time but also enhance productivity. By integrating a label counter machine into your business, you streamline your labeling process, improve inventory accuracy, and reduce manual errors.

For businesses looking for reliability and high performance, options like the Labelmate RRC-400-U Large Form Reel-to-Reel Label Counter or the Autoprint 300 Reel-to-Reel High-Speed Counter provide excellent solutions. By choosing the right tools and equipment, you can elevate your business’s efficiency and stay ahead in the competitive landscape.

To learn more about optimizing your labeling process, visit DuraFast Label Company, where we offer a wide range of products like thermal transfer labels for sale and other solutions to help your business thrive.