How To Choose the Right Heat Shrink Tubing Sizes for Wire and Cable Labeling?

30th Jan 2026

Key Highlights

-

Heat shrink tubing must be selected based on pre-shrink diameter plus shrink ratio for a proper final fit.

-

Measuring only the bare wire is wrong. Always measure the largest point (connector/crimp/splice).

-

Standard sizes like 1.2 mm to 25.4 mm+ are available, but shrink ratios (2:1 / 3:1 / 4:1) change the final grip.

-

For printing, choose a slightly bigger tubing so it lies flat during printing and shrinks clean later.

-

Common mistakes include mixing AWG + mm, ignoring shrink ratios, and overheating sleeves during shrinking.

-

MAX Letatwin printers from DuraFast are optimised for the right tube diameters and deliver clean, consistent printed results.

Heat-shrink labeling might look simple, but the tubing diameter you choose directly determines how clean your final result will be. When the size is off even slightly, the sleeve can shrink unevenly and ruin the finish.

The goal is to match the sleeve size to the wire correctly before printing, not after. When the tubing fits comfortably before shrinking and seals uniformly after shrinking, the print stays flat, the grip stays secure, and the sleeve doesn’t wrinkle or twist around the cable.

In this guide, we’ll show you how to measure properly, how shrink ratios influence the final fit, what sizes to choose for common wire gauges, and the most common sizing mistakes to avoid. You’ll also find an easy reference chart to ensure your heat-shrink labels look sharp and professional every single time.

What Is Heat Shrink Tubing and Why Is Size Important?

Heat shrink tubing is a protective plastic sleeve that shrinks tightly around wires, connectors, and joints when heat is applied. It provides insulation, environmental sealing, mechanical protection, and strain relief, especially in electrical and automotive applications where wires are exposed to harsh environments involving friction, moisture, or vibration. Once heated, it forms a firm barrier that shields the connection from damage and keeps everything neat and secure.

Because these functions rely on a proper seal, the size of the tubing becomes critical. The sleeve must be wide enough to slide over the wire or connector before shrinking, yet still shrink down tight enough to grip firmly afterwards. If that balance isn’t right, the performance benefits you expect from heat shrink simply won’t happen.

If the tubing is too loose, it won’t seal well, allowing moisture or dust to enter. If it’s too tight, it won’t fit over connectors during installation. Choosing the right inner diameter and shrink ratio ensures easy installation and a snug, durable result once heated.t.

So, choosing the right inner diameter and shrink ratio ensures easy installation plus a snug, durable fit once heated.

How Does Heat Shrink Ratio Affect Tubing Size?

Heat shrink ratio tells you how much the tubing will reduce in diameter once heat is applied. For example, a 2:1 shrink ratio means the tubing will shrink to half its original size, while a 3:1 ratio shrinks to one-third, and a 4:1 ratio shrinks even more. Higher ratios are useful when you need to cover components with big size variations. For instance, a bulky connector on one end and a thin wire on the other.

This ratio directly influences what size tubing you should select. You need a size that’s large enough to slide over the biggest part of your assembly before heating, but that also shrinks down tight enough to seal securely around the thinnest section after shrinking.

In short, higher shrink ratios give you more flexibility for uneven shapes, while lower ratios provide a neater fit when diameters are consistent.

What Are Standard Heat Shrink Tubing Sizes?

Heat shrink tubing comes in many diameters, starting from very small sizes for single conductors all the way up to large sizes for thick cable bundles. These diameter values always refer to the tubing before shrinking, which is why knowing the shrink ratio (2:1, 3:1, 4:1) is important when matching the tubing to your wire or connector.

Common pre-shrink sizes include:

-

1.2 mm (1/16") — single wires / PCB leads

-

3.2 mm (1/8") — small splices / thin automotive wires

-

6.4 mm (1/4") — standard automotive / electronics harnesses

-

9.5 mm (3/8") — thicker bundles and cable pairs

-

12.7 mm (1/2") — medium connectors/cable jackets

-

19.1 mm (3/4") — heavy-duty terminal insulation

-

25.4 mm (1") and above — large cable bundles / industrial use

Most of these common diameters are available in common ratios like 2:1, 3:1, and 4:1. This means you can pick the right size based on how much reduction you need after heating.

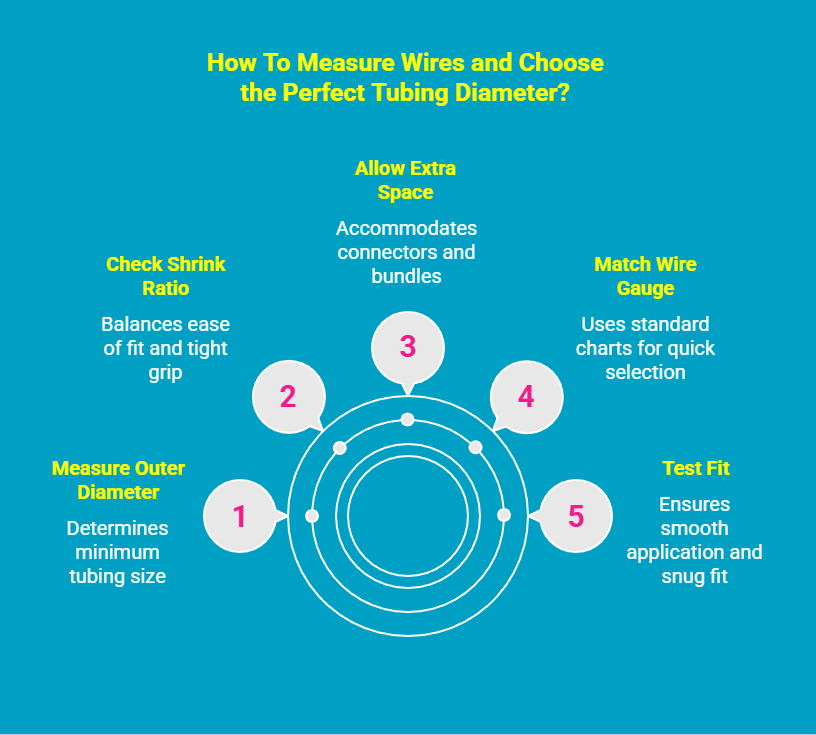

How To Measure Wires and Choose the Perfect Tubing Diameter?

Selecting the right heat shrink tubing starts with knowing the appropriate size and choosing a tubing diameter that easily slides over the largest part of the assembly before shrinking. So, here are the key steps you need to follow if you are unsure how to choose heat shrink tubing size:

Step 1 – Measure the Outer Diameter of the Wire or Cable

Use a caliper, ruler, or manufacturer's spec sheet to note the outer diameter, not just the copper core. This number tells you the minimum size your tubing needs to fit over.

Step 2 – Check the Shrink Ratio of the Tubing

Once you know the diameter, confirm if your tubing is 2:1, 3:1, or 4:1. This tells you how small it can shrink down, which helps you balance fits over before heating and shrinks tight enough after.

Step 3 – Allow Extra Space for Connectors or Cable Bundles

If the cable has crimp terminals, solder joints, or multiple conductors, factor that in next. Even if the wire diameter fits, the connector may be the thickest point, so step up to a slightly larger pre-shrink size accordingly.

Step 4 – Match the Tubing Diameter With the Wire Gauge

With those details in place, cross-reference AWG or mm² against sizing charts to narrow down to the most suitable diameter range, especially helpful for repeat jobs or large volume runs.

Step 5 – Test Fit Before Heating or Shrinking

Finally, do a dry fit. If the sleeve slides over smoothly and you can already tell it will shrink down snugly, you have selected the right size and you will get a professional finish once heat is applied.

Heat Shrink Size Chart & Measurement Guide for Label Printing

When printing on heat shrink sleeves, sizing is crucial because the sleeve shrinks after printing. Always choose a tubing diameter that easily slides over the wire before shrinking and still fits snugly after shrinking. This ensures the text stays readable and prevents distortion or wrinkling.

Here is a quick heat shrink tubing size guide for you:

|

Wire Gauge (Approx.) |

Typical Pre-Shrink Tubing Size Used for Printing |

Typical Use Case |

|---|---|---|

|

24–22 AWG |

1.6 mm – 2.4 mm |

Single thin conductors / small signal wires |

|

20–18 AWG |

3.2 mm |

Basic automotive/low-voltage wiring |

|

16–14 AWG |

4.8 mm |

General-purpose cable bundles |

|

12–10 AWG |

6.4 mm – 9.5 mm |

Larger automotive cables/power feeds |

|

8 AWG and above |

12.7 mm – 25.4 mm+ |

Thick battery cables / industrial harnesses |

For example, if you’re wondering what size heat shrink tubing for 14 gauge wire, the chart shows 16–14 AWG typically uses around 4.8 mm pre-shrink size for printing. So you’d start with ~4.8 mm tube (and choose the ratio based on how tight you want the final seal).

Similarly, if you’re thinking what size heat shrink tubing for 18 gauge wire, the chart shows 20–18 AWG typically uses around 3.2 mm pre-shrink size for printing, which will lie flat during printing and shrink down cleanly after heating.

Tip: For label readability, choose a slightly larger pre-shrink diameter than usual so the sleeve lies flat during printing. Then use an appropriate shrink ratio (2:1 / 3:1 / 4:1) to tighten it down cleanly during installation. This approach ensures the label prints clean, shrinks clean, and remains readable even after final installation.

Want additional tips to master label printing? Check out this Ultimate Guide to Label Printing: Everything You Need to Know

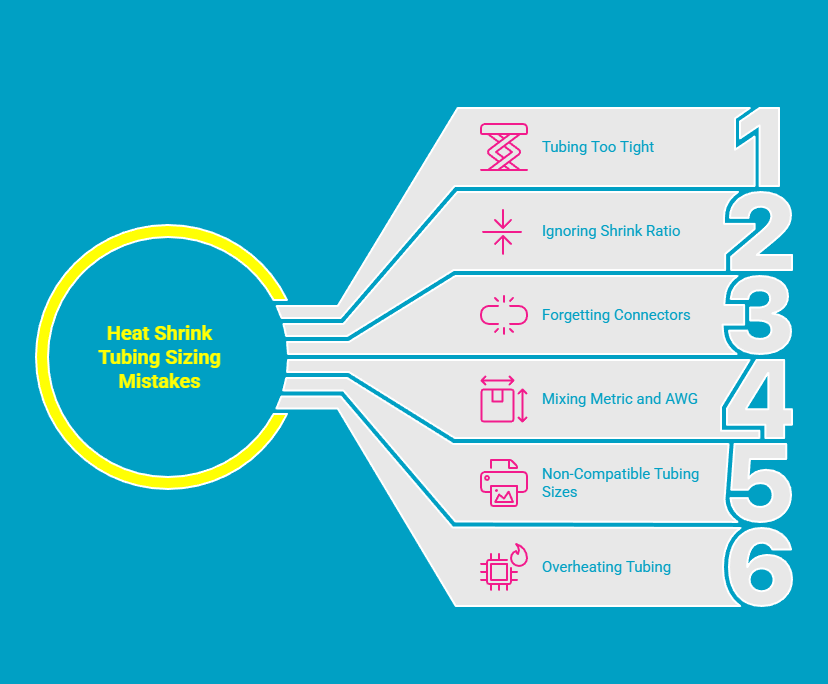

What Are the Top Sizing Mistakes People Make With Heat Shrink Tubing, and How To Fix Them?

Even experienced installers make sizing errors with heat shrink tubing, especially when printing labels. They lead to poor fit, label distortion, or sleeves that simply won’t slide over the wire. Below are the most common mistakes and the quick fixes.

1. Choosing Tubing That’s Too Tight for the Wire Diameter

A very common mistake is selecting tubing that matches the wire diameter too closely, forgetting that the tubing needs to slide over the wire before shrinking. When the fit is extremely tight, installers end up forcing the sleeve on, which can cause stretching, tearing, or incomplete seating.

Fix: Always choose a pre-shrink size that is at least 20–30% larger than the measured outer diameter of the cable or wire so it can slide on smoothly before heat is applied for a secure fit.

2. Ignoring the Shrink Ratio Before Selecting the Size

People often look only at the listed diameter and ignore the shrink ratio. However, a 6 mm sleeve in 2:1 performs completely differently than a 6 mm sleeve in 3:1. Without accounting for how much it shrinks, you end up with tubing that either shrinks too little (loose seal) or shrinks too much (distortion).

Fix: First, confirm the ratio (2:1 / 3:1 / 4:1), then confirm both pre-shrink and post-shrink fit based on your wire dimensions.

3. Forgetting To Measure Over Connectors or Cable Ends

Many installers measure only the bare wire and forget that connectors, solder joints, ferrules, and crimp terminals dramatically increase the original diameter. The result? Tubing that won’t even slide over the connection point.

Fix: Measure the largest part of the assembly (usually the connector or joint) and select tubing based on that maximum diameter instead of the bare cable.

4. Mixing Metric and AWG Measurements Incorrectly

Heat shrink is often listed in mm or inches, while wires are frequently referenced using AWG. People assume these map 1:1, but they don’t, and this leads to accidental undersizing or oversizing.

Fix: Avoid guessing. Either standardise to one measurement format for the entire project (mm or inch), or use a proper conversion chart when matching AWG to tubing diameter.

5. Using Non-Compatible Tubing Sizes With Label Printers Like MAX Letatwin

MAX Letatwin and similar industrial label printers have specific heat shrink diameters they are optimised for. Using off-spec sizes can cause feeding issues, rolling/rounding, and poor surface flatness, which directly affects print clarity.

Fix: Stick to the manufacturer’s recommended tubing sizes (e.g., 2.5 mm, 3.5 mm, 5.5 mm, 8 mm for MAX Letatwin) to ensure flat, stable printing performance.

Want more tips on industrial label printing? Check out this Beginner’s Guide to On-Demand Industrial Label Printing

6. Overheating the Tubing and Distorting Printed Labels

Even if you have achieved the right fit, too much heat ruins everything. It can bubble the sleeve surface, cause uneven shrinking, and even smear or fade the printed text. This often happens when users try to shrink too quickly with excessive heat.

Fix: Apply controlled, gradual heat in passes and not direct flame. This ensures that the sleeve shrinks evenly and the printed label remains crisp and readable after installation.

Why the Right Tubing Size Matters for Professional Labeling Results?

When you’re printing on heat shrink tubing, sizing isn’t just a mechanical fit issue; it directly impacts how durable your printed text ends up. Here are some reasons why the right tubing size matters for professional labeling results:

-

If the sleeve is too small, it won’t lie flat during printing, which leads to warping, skewed alignment, and ink smudging.

-

If it’s too large, the label might print cleanly, but once shrunk, the text can stretch or become difficult to read.

-

The right size ensures better repeatability and a more predictable finish. When the tubing diameter matches the wire, connector, and shrink ratio correctly, the shrink is consistent. This means the printed characters maintain their legibility, spacing, and contrast even after heat application.

-

The right size reduces wasted sleeves, avoids printer jams, and makes installation smoother.

So when you get the size right upfront, you’re not just fitting tubing; you’re protecting label quality end-to-end.

Need a Reliable Printer for Heat Shrink Tube Labeling? Explore MAX Letatwin at DuraFast

When clarity and durability matter in labeling heat-shrink tubing, the MAX Letatwin LM550A3BH/PC Tube and Tape Printer for Electrical Marking LM99013 from DuraFast delivers. Built specifically for electrical and wiring applications, it’s designed to handle tube and tape printing with precision and speed.

With support for tubing sizes optimised for heat-shrink applications and a professional print output, it ensures the labels remain legible even after shrinking. For users who need reliable results across wire harnesses, control panels, or wiring looms, this model offers the strength and flexibility to do the job right.

Conclusion

Getting heat-shrink sizing right is the single easiest way to guarantee clean, accurate, professional labeling results. When you measure properly, account for connectors, choose the right shrink ratio, and select the correct pre-shrink diameter, everything else becomes smoother. Printing is cleaner, shrinking is more predictable, labels stay readable, and installations look factory-grade rather than improvised. Ultimately, when you know how to size heat shrink tubing correctly, you don't just protect the wire; it protects the quality of the label itself.

Frequently Asked Questions

What is heat-shrink tubing, and where is it used?

Heat-shrink tubing is a plastic sleeve that shrinks when heated to insulate, seal, protect, and label wires. It’s widely used in electrical wiring, automotive harnesses, solar installations, control panels, electronics assembly, repairs, and cable management.

How do I read a heat shrink tubing size chart to find the correct tubing for my wire?

You simply match your wire’s outer diameter with the tubing’s expanded (pre-shrink) size, then check that the recovered (post-shrink) size is smaller than the wire so it can still tighten securely after heating.

What measurements do I need before choosing the right heat shrink tubing size?

You mainly need the outer diameter of the wire, plus the maximum diameter over connectors, splices, ferrules, or cable ends. These are always bigger than the bare wire and determine the minimum expanded size the tubing must slide over.

Can you explain the difference between expanded and recovered diameter in heat shrink tubing charts?

Expanded diameter is the tubing’s original size before heat is applied, while recovered diameter is the final size after shrinking. Charts show both, so you can confirm the tubing fits easily before shrinking and grips tightly afterwards.

What happens if I use heat shrink tubing that is too large or too small for my wire?

If the size of heat shrink tubing is too large, the sleeve won’t grip the wire tightly after shrinking. If too small, it may not slide over connectors at all or may tear while forcing it on, resulting in wasted sleeves and a poor finish.

How precise do my measurements need to be when using a heat shrink tubing sizing chart?

While accurate measurements are important, they don’t need to be exact to decimal precision. A tolerance of about half a millimetre is usually fine, as long as the tubing’s shrink ratio gives enough room for both slide-on and final seal.

Are there differences in size charts for various heat shrink tubing materials?

Yes, different materials have different shrink behaviours. Standard polyolefin, adhesive-lined, high-temperature, and printer-grade sleeves can all have unique shrink ratios and wall thicknesses, so their size charts are not always interchangeable across categories.