How Private Labeling is Changing the Retail Landscape: What Businesses Need to Know

4th Aug 2025

Private labeling isn’t just a buzzword anymore—it’s reshaping how retailers compete, grow, and retain loyal customers. For decades, national brands dominated the shelves. But today, consumer confidence in store brands is rising. Over 47% of shoppers now prefer private label products over name brands, and that number is growing fast. Add in supply chain disruptions, margin pressure, and changing customer expectations, and the shift becomes clear: owning the label gives businesses more control and more profit.

And for small and mid-sized brands, this shift is a real opportunity.

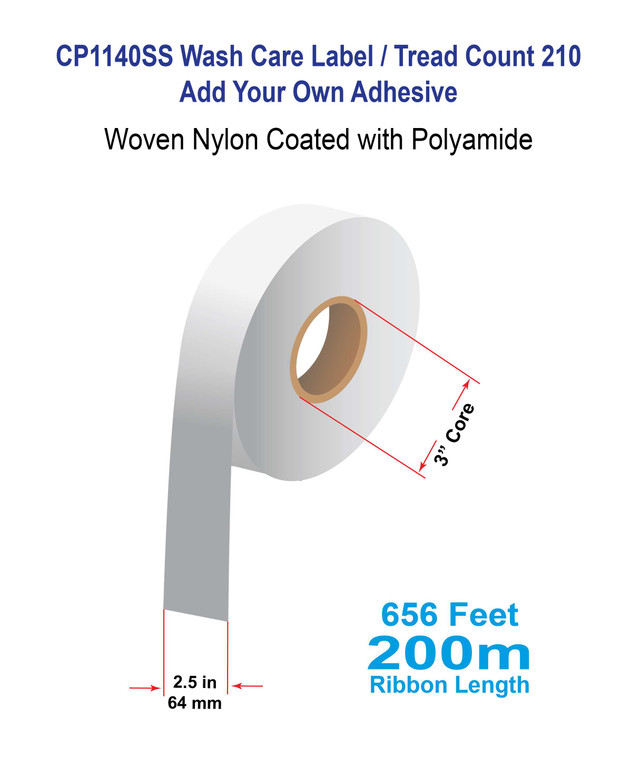

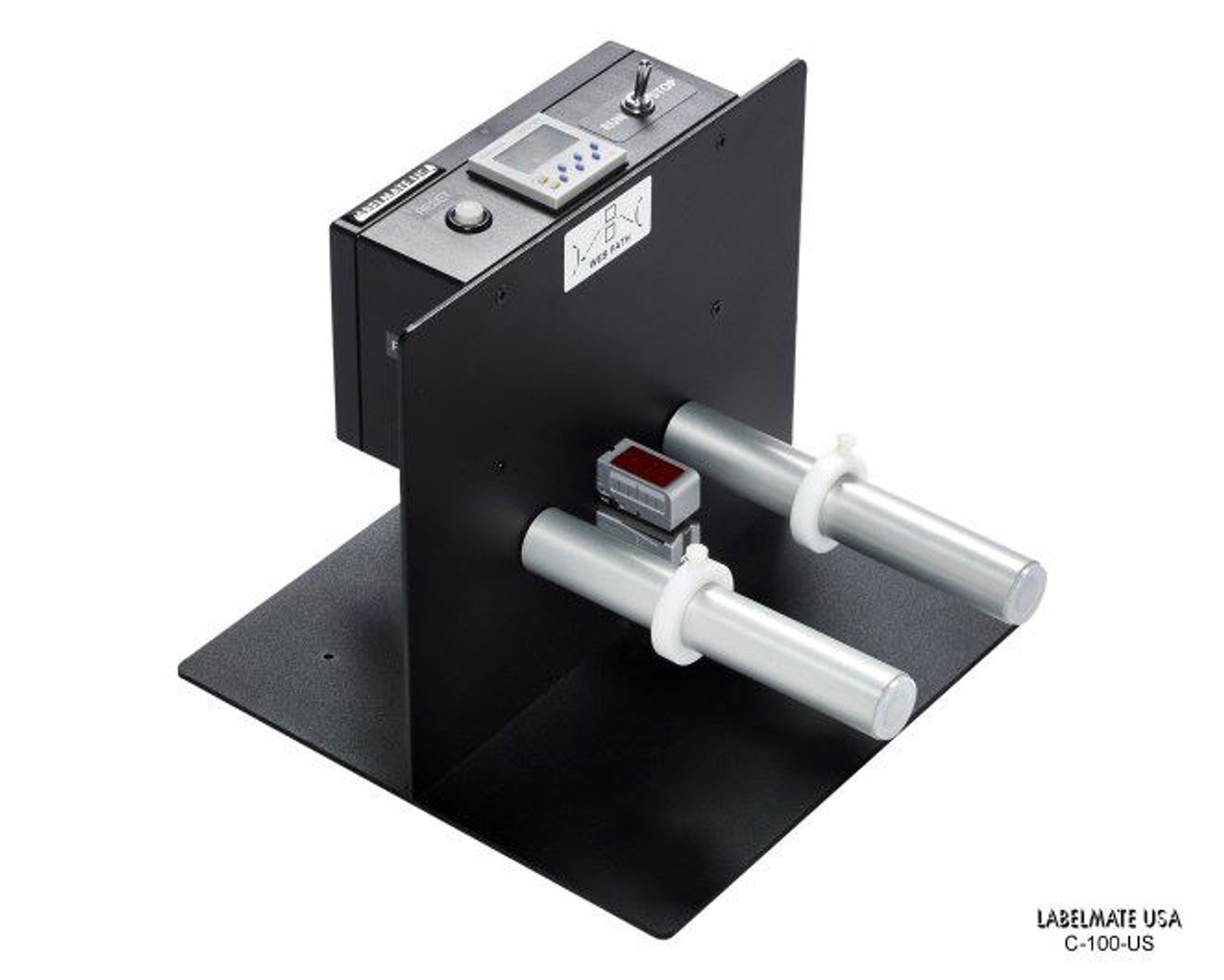

At DuraFast Label Company, we help businesses take advantage of that opportunity by offering high-performance label printing solutions for private labeling. Whether you're launching a new product line or upgrading your packaging quality, our range of thermal transfer labels, premium topcoated direct thermal labels, and blank inkjet labels ensures your product looks as good as it performs. We also provide label counter machines, toners for label printers, and the best portable label makers for home use and small business setups.

In this article, we’ll look at why private labeling is gaining momentum, how it benefits businesses, how to build brand equity through smart packaging, and why label quality plays a major role in success.

Why Private Labeling Is Becoming a Preferred Strategy

Private labeling allows businesses to control everything about their products—from ingredients to packaging to pricing. It’s a shift from being a seller of products to being a creator of brands. Here are some key reasons why more companies are adopting this model:

- Higher Profit Margins: Without a national brand’s markup, retailers can generate better profit while offering competitive pricing.

- Brand Loyalty: Custom product lines help businesses build a distinct identity that customers come back to.

- Supply Chain Flexibility: Private labeling lets you choose and change suppliers without being locked into national brand contracts.

- Pricing Control: Companies can adjust pricing without worrying about national brand standards or MAP pricing.

- Speed to Market: With direct oversight, businesses can quickly test and launch new products.

Consumers today are also more accepting of store brands. In fact, many now associate private label products with quality and affordability, particularly in health, wellness, and grocery categories.

Benefits of Private Labeling for Businesses of All Sizes

Private labeling isn’t reserved for massive national retailers anymore. In fact, it’s increasingly being used by small and mid-sized businesses that want to break into competitive categories without the weight of building or distributing third-party brands. Whether you're launching a specialty food item, a cosmetic line, or a line of office supplies, private labeling creates an opportunity to take full control of the product, the brand, and the customer experience.

For businesses of all sizes, private labeling offers strategic advantages that can be transformative:

1. Full Brand Control

When you own the brand, you own the message. Private labeling puts businesses in the driver’s seat when it comes to every aspect of brand identity and perception.

What this looks like in practice:

- Designing packaging that aligns with your brand's aesthetics and values

- Setting your own pricing without competing against the same product sold elsewhere

- Creating a customer journey that is consistent, from shelf to social media

This level of control means your brand stands for more than just a product—it becomes an experience that customers trust.

2. Exclusive Product Offerings

One of the most effective ways to differentiate your business is to offer products that consumers can’t find anywhere else. Private labels allow you to do just that.

Why this matters:

- You’re not fighting over price with identical SKUs

- You reduce direct competition, especially in saturated markets

- You can command more attention and potentially higher margins by highlighting product uniqueness

Exclusivity can be a powerful hook. It invites curiosity, fosters loyalty, and helps turn occasional buyers into repeat customers.

3. Stronger Customer Relationships

When you rely on third-party brands, you’re removed from the customer feedback loop. With private labeling, you gain direct access to the voice of the customer—and you can act on it faster.

This gives you the power to:

- Adjust product features or formulations based on buyer feedback

- Address issues immediately without waiting for a supplier to respond

- Show customers that their input has a direct impact on the products they love

These actions build trust and strengthen the brand-customer relationship over time. Repeat purchases become more likely, and referrals increase when customers feel heard and valued.

4. Data Ownership and Strategic Insights

Private label products give businesses access to high-quality, first-party data. This includes everything from customer demographics to performance across different retail channels.

How businesses use this data:

- Identify top-performing SKUs and expand the line strategically

- Test pricing models to find the optimal profit-to-volume ratio

- Spot opportunities to introduce complementary products based on buyer behavior

The direct feedback loop not only shortens the time between learning and action, but also reduces guesswork in product development and marketing strategy.

5. Scalability and Long-Term Growth

A well-positioned private label can scale far more efficiently than reselling another company’s brand. Since the brand is fully owned, all growth efforts feed directly back into the business.

Scalability advantages include:

- The ability to negotiate better manufacturing terms as volume increases

- Seamless product line expansions that strengthen brand equity

- Building brand loyalty that leads to higher customer lifetime value

Unlike traditional wholesale or white-label relationships, private labeling puts the focus on building your brand—not someone else’s.

Why Even the Smallest Businesses Are Getting In

Private labeling no longer requires massive investment or extensive infrastructure. With access to on-demand manufacturing, digital marketing channels, and small-batch production runs, even micro-brands can enter the market quickly and cost-effectively.

Whether you're printing affordable blank inkjet labels in-house, managing inventory with a label counter machine, or launching your first line with portable label makers for home use, the tools to start and scale are now accessible. That’s changed the game completely—especially for businesses that want to create something their customers can't find anywhere else.

Building a Strong Private Label Brand: What Matters Most

A private label strategy only works when the brand behind it is positioned to earn customer trust and drive repeat business. While pricing plays a role, success is built on far more than competitive costs. Customers associate private label products with the brands that stand behind them. That means your brand's reputation—good or bad—is tied to every product you sell under your name.

Over the years, we’ve seen what separates high-performing private labels from those that struggle. It comes down to a few key elements: presentation, consistency, clarity, customer experience, and compliance.

1. Packaging Design and Label Quality

The first physical impression of your brand almost always comes from the label. It’s the first thing customers see when scanning a shelf or browsing online. If it looks generic, cheap, or poorly aligned with the product's promise, that perception carries over to the brand itself.

Why label quality is essential:

- Customers associate label quality with product quality.

- Labels communicate everything from branding to ingredients to usage.

- Poor adhesion, smudging, or faded text signals carelessness and reduces trust.

Businesses that take packaging seriously often use in-house printing solutions to maintain control over quality, branding consistency, and production schedules. This flexibility can be the difference between lagging and leading.

Label options that support strong packaging:

- Premium topcoated direct thermal labels offer excellent resistance to smudging and abrasion—ideal for high-volume SKUs or fast-moving consumer goods.

- Affordable blank inkjet labels are excellent for small batches where full-color branding flexibility is key. They allow rich, vibrant label designs without outsourcing.

- Thermal transfer labels provide long-lasting durability and are a smart choice for products exposed to extreme heat, cold, or friction.

In short, investing in the right label materials enhances product presentation and builds long-term credibility.

2. Consistency Across SKUs

Consistency is more than a design principle—it’s a trust signal. Whether your brand sells personal care products, condiments, or office supplies, customers expect a seamless experience across every SKU.

Areas where consistency matters:

- Label appearance and tone of voice: The design, colors, and fonts should align across all packaging.

- Product names and claims: Clear naming conventions help customers understand your line and make confident repeat purchases.

- Label performance and finish: Glossy or matte? Thermal or inkjet? Whichever you choose, the same type of finish should be used consistently across product lines.

Operationally, maintaining this level of consistency requires the right tools:

- A label counter machine helps monitor output to prevent packaging mix-ups.

- Portable label makers offer flexibility when adding new SKUs quickly or adjusting designs in real-time.

- High-quality toners for label printers ensure color fidelity and label clarity—both essential to consistent presentation.

These aren’t luxuries—they’re foundational to brand integrity.

3. Clear Brand Positioning

A strong private label doesn’t try to be everything to everyone. Instead, it’s positioned around a clear promise that speaks to a specific audience. That promise should influence product development, packaging design, marketing strategy, and customer interaction.

Examples of effective positioning:

- A brand built around clean ingredients will use simple, transparent labels and minimalistic design.

- A budget-focused brand might emphasize quantity or functionality with bold claims and utilitarian labeling.

- A luxury brand might use understated color schemes, soft-touch packaging, and minimalist text.

Whatever your positioning, your labels should reflect that brand promise from the moment they’re seen. Using blank inkjet labels or laser sheet labels, for instance, gives businesses greater control over custom messaging and design aesthetics—whether that means colorful graphics or precision detailing.

When brand positioning is clear, customers know exactly what they’re buying—and they’re more likely to come back.

4. End-to-End Customer Experience

Many businesses underestimate the power of packaging in shaping the customer experience. While product performance matters most, presentation influences perceived value, satisfaction, and unboxing excitement. In online retail especially, packaging is often the only tangible touchpoint customers have with your brand.

Key factors that affect the experience:

- Label readability: Instructions, ingredients, or usage warnings should be easy to understand, not cluttered or hidden in fine print.

- Clean application: A crooked or bubbling label leaves a poor impression, even if the product is excellent.

- Packaging cohesion: Labels, containers, and inserts should look like they belong together.

Consider the difference between a bottle with a smudged or peeling label and one that uses non-topcoated direct thermal labels that hold up well in storage and transit. Or a package with an inkjet label that displays vibrant colors and clear branding.

The better the label quality and fit, the better the perceived value—especially for first-time buyers.

5. Industry and Regulatory Compliance

Private labeling means taking full responsibility for what’s on the label, especially in regulated categories like supplements, cosmetics, and food. Errors in labeling can lead to consumer harm, lost sales, or even legal action.

What compliance involves:

- Including all required regulatory text (ingredients, allergens, usage, etc.)

- Following FDA, USDA, or other relevant labeling standards

- Ensuring label durability for the product’s lifecycle (e.g., refrigeration, shipping, handling)

Certain label types are better suited for regulatory adherence:

- Laser sheet labelsprovide a crisp, clear finish ideal for small fonts and ingredient panels.

- Custom thermal transfer labels ensure longevity and resistance to environmental factors.

- Thermal transfer labels are often used for logistics and barcoding, supporting traceability.

By meeting regulatory requirements without compromising design or functionality, businesses reduce risk and reinforce consumer trust.

Labeling Strategies That Influence Consumer Decisions

Great products need great presentation—but that presentation isn’t just about looking attractive. Strategic labeling can guide consumer choices, influence brand perception, and reinforce the value of a product long before the buyer ever opens the package.

Whether a product sits on a physical shelf or appears in a search result thumbnail, packaging is your silent salesperson. Private label businesses that approach labeling strategically—rather than as an afterthought—consistently outperform those that don’t.

Here are some of the most effective labeling strategies brands are using today:

1. Segmenting Product Lines by Design

Customers love simplicity. If your private label brand carries multiple SKUs, making it easy to navigate those options visually is critical. One of the most effective ways to do this is through design segmentation—intentionally varying label aesthetics within a unified brand structure.

How brands segment products visually:

- Color-Coding: Assigning a distinct color to each product category (e.g., green for mint, blue for ocean breeze, red for cinnamon) allows consumers to identify the variant they want instantly. This tactic is highly effective in personal care, cleaning products, and food packaging.

- Material Finishes: Using different label materials or finishes (glossy vs. matte, foil stamping, soft-touch laminates) creates a tactile and visual distinction between premium and value tiers.

- Shape & Size Variations: Adjusting label shapes—oval, square, wraparound, etc.—or sizes can communicate different functions or price points even within the same brand.

With in-house label printing capabilities—using blank inkjet labels, thermal transfer labels, or even laser sheet labels—businesses can segment products affordably while maintaining brand consistency. The flexibility to switch colors or finishes quickly supports agile product development and faster time-to-market.

2. Using Labels to Communicate Benefits

Labels are more than just product names and barcodes—they’re also communication tools. Successful brands use the front-facing portion of their labels to highlight key benefits, features, or outcomes, not just ingredients or specs.

Examples of benefit-forward labeling:

- “Lasts 48 Hours” on a deodorant

- “Cold-Pressed & Organic” on a juice bottle

- “Kills 99.9% of Germs” on a surface cleaner

- “Eco-Friendly & Refillable” on a skincare container

This tactic works especially well when launching a private label in a competitive market. It gives consumers a reason to choose your product over more established options.

Implementation tip:

Use in-house label printers like portable label makers or high-speed color label printers to test different wording and design placements before committing to large print runs. This enables you to A/B test messaging quickly and refine based on real-world performance.

3. Leveraging QR Codes for Deeper Engagement

As consumers become more comfortable with digital experiences, QR codes have become a powerful tool for adding depth to a label without cluttering it.

What you can link with a QR code:

- Detailed product instructions or usage videos

- Promotions or loyalty programs

- Customer reviews or testimonials

- Ingredient sourcing or sustainability commitments

- Recipes, how-to guides, or refill reminders

For private label brands, QR codes are a cost-effective way to create a more interactive customer experience. They add value and foster engagement without adding to the product's packaging cost or complexity.

Printing QR codes efficiently:

Both blank inkjet labels and thermal transfer labels can handle high-resolution QR printing. Using in-house printing allows brands to customize QR code destinations for different regions, batches, or campaigns. This is especially helpful when testing offers or tracking customer interaction via UTM links or analytics tools.

4. Flexible Label Printing In-House

Speed is everything when you're scaling or testing new private label products. Traditional outsourced label printing often means long lead times, high MOQs (minimum order quantities), and limited room for quick pivots. That’s why many brands are investing in in-house label printing solutions.

Benefits of printing labels in-house:

- Rapid Prototyping: Launch a test version of a product with a limited-edition label in hours, not weeks.

- Seasonal & Regional Variations: Adjust labels for holiday promotions, local events, or climate-specific messaging.

- Reduced Waste: Print only what you need and update labels as needed without writing off old inventory.

- Greater Customization: Tailor ingredients lists, instructions, or languages for niche audiences.

Tools that support this flexibility:

- Portable label makers are great for small-batch runs, artisan products, or businesses just starting with private labels.

- Mid-range inkjet or laser printers can produce retail-ready full-color labels on demand using blank inkjet or laser sheet labels.

- High-speed label printers support industrial-scale output without sacrificing quality or customization, ideal for fast-growing brands.

By controlling label production internally, private label businesses can adapt to trends faster, iterate more freely, and maintain consistency across packaging—even while scaling.

Common Challenges in Private Labeling and How to Address Them

While the benefits are clear, private labeling isn’t without its challenges. Here are some common issues and ways to manage them:

1. Inconsistent Branding

If different batches look or feel different, customers will notice. Use tools like a label counter machine and laser sheet labels to standardize your process.

2. Low-Quality Printing

Toner smudges, unclear fonts, or blurry graphics reflect poorly on your brand. Investing in reliable toners for label printers and premium topcoated direct thermal labels ensures quality.

3. Limited Production Capabilities

Scaling up means printing more labels quickly without compromising on quality. In-house systems using non-topcoated direct thermal labels or thermal transfer options help meet demand affordably.

4. Design Bottlenecks

Waiting for external designers or printers slows you down. Blank inkjet labels and portable label makers give your team the tools to design and test quickly.

How Consumer Expectations Are Evolving

Today’s consumers are informed, values-driven, and brand-conscious. They want:

- Transparency

- Responsibly sourced ingredients

- Clear labeling

- Competitive pricing

Retailers who succeed in private labeling meet these needs with clarity and intention. Labels play a vital role here. A well-designed label communicates trust. It tells a story. It confirms legitimacy.

You don’t need to spend like a national brand to get those results. A good thermal transfer label printer and affordable blank inkjet labels can give your packaging the polished look that customers expect.

Product Categories Seeing the Fastest Growth in Private Labeling

While nearly every category is seeing some level of private label growth, a few stand out:

- Health and Wellness Products

- Personal Care and Beauty

- Pet Supplies

- Organic and Natural Foods

- Home and Cleaning Supplies

Each of these sectors benefits from clear, attractive, compliant labeling. For example:

- Non-topcoated direct thermal labelswork well for short-life products.

- Premium topcoated direct thermal labelsoffer durability for refrigerated or frequently handled items.

- Thermal transfer labelswithstand moisture and heat.

Smart Labeling = Smarter Business

Smart packaging is more than just a look. It’s a business strategy. With the right label printers and supplies, companies can:

- Reduce waste

- Speed up product development

- Cut outsourcing costs

- Boost margins

Label counter machines, blank inkjet labels, and portable label makers reduce dependency on third-party suppliers. You can keep your designs in-house, produce only what you need, and respond to changes quickly.

Smart labeling also supports better marketing. A QR code, a social media tag, or even a loyalty code printed directly on your laser sheet labels can help you build deeper relationships with your audience.

Is Your Packaging Helping or Hurting Your Sales?

In retail, perception is everything. Consumers make snap judgments based on packaging. A product may be excellent inside the bottle or bag, but if the label looks amateurish, the customer may never give it a chance.

At DuraFast Label Company, we provide businesses with tools to ensure every product they label looks professional, reliable, and ready to sell. Our wide range of label printing supplies includes everything from custom thermal transfer labels to non-topcoated direct thermal labels, as well as high-speed machines and blank inkjet labels.

If you're building a private label product line—or even thinking about starting one—you need the right printing tools and supplies to support your growth. Our team is here to help you find the right equipment and materials that fit your specific needs.

Order from DuraFast Label Company today and see how the right labels can help your brand stand out, impress customers, and support long-term growth.