Label Printing Taking Too Long? Speed Up Production with These Pro Tips

11th Jun 2025

If your label printing process is slowing down your business, you’re not alone. Delays in producing labels can disrupt inventory management, delay shipments, and frustrate customers. Whether you’re running a small retail operation or a large manufacturing facility, optimizing your label printing workflow is essential for staying competitive. This guide provides detailed strategies to speed up your label printing by selecting faster printers, using efficient software, and implementing automation to handle high-volume printing effectively.

Choose Faster Printers for Your Needs

The right printer can significantly reduce your label printing time, especially if you’re dealing with high volumes or complex designs. Modern label printers are designed for speed, but you need to pick one that matches your specific requirements. Here’s how to make the best choice.

Understand Your Volume and Speed Requirements: Start by assessing how many labels you print daily or weekly. If you’re a small business printing 500 labels a day for retail products, a desktop printer like the Primera LX910, which prints up to 4.5 inches per second, is sufficient. For industrial operations printing thousands of labels, like a warehouse labeling shipping boxes, an industrial printer like the Zebra ZT610, capable of 14 inches per second at 203 dpi, is ideal. Check the printer’s specifications for print speed, measured in inches per second (ips), to ensure it meets your demand.

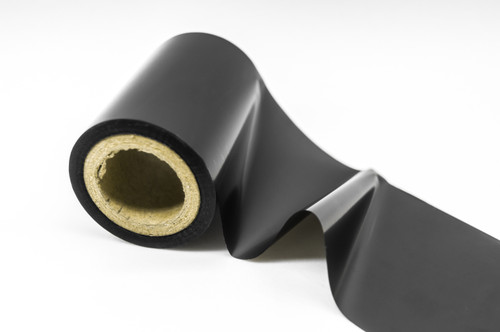

Opt for Thermal Transfer or Inkjet Technology: Thermal transfer printers, like those using Zebra ribbons, are fast and durable, making them perfect for high-volume tasks. They use heat to transfer ink from ribbons onto labels, producing crisp prints that resist smudging. You can buy thermal transfer printers for consistent performance in logistics or manufacturing. Inkjet printers, such as the Epson ColorWorks C6000 series, excel for color labels, printing up to 5 inches per second with vibrant results. If you need colorful retail labels, inkjet is a great choice, but ensure you buy ink cartridges for printers to maintain speed and quality.

Consider Printer Features for Efficiency: Look for printers with features that minimize downtime. Auto-cutters, like those on the Afinia L901, automatically trim labels after printing, saving you manual cutting time. Peel-and-present functions dispense labels one at a time, speeding up application in busy environments. High-capacity ribbon and label roll holders reduce the frequency of reloading, which is critical for continuous printing. For example, the VIPColor VP750 supports large rolls, allowing you to print thousands of labels without stopping.

Match Printers to Label Types: Ensure your printer is compatible with your label materials, such as thermal transfer labels for sale or premium topcoated direct thermal labels. Mismatched printers and labels can cause jams or slow printing. For instance, direct thermal printers are fast for short-term labels, like shipping tags, but they’re slower for durable synthetic labels compared to thermal transfer models. Test your labels with the printer to confirm speed and reliability.

By selecting a high-speed printer tailored to your volume and label type, you can cut printing time significantly. Regularly maintain your printer with cleaning kits to prevent slowdowns from dust or ink buildup.

Use Efficient Software to Streamline Design

Label design and printing software can make or break your workflow. Inefficient software leads to slow design processes, printing errors, and wasted time. Here’s how to choose and use software to speed up your label printing.

Select Professional Label Design Software: Programs like BarTender or NiceLabel are designed for fast, accurate label creation. You can buy barcode printing software online to access these tools, which offer templates for common label formats, reducing design time. For example, BarTender includes pre-set layouts for GHS chemical labels or food nutrition labels, so you don’t have to build designs from scratch. These programs also support variable data printing, letting you print thousands of unique labels, like serial numbers or barcodes, in one batch without manual edits.

Optimize Design for Speed: Simplify your label designs to reduce printing time. Complex graphics or high-resolution images can slow down printers, especially on older models. Use vector-based graphics for logos or icons, as they process faster than bitmap images. Limit the number of colors if your printer supports fewer ink channels, such as a four-color inkjet model. For barcodes, ensure they meet GS1 standards for scannability, avoiding reprints due to errors. Test your design on a small batch to confirm it prints quickly and clearly.

Integrate with Data Systems: Connect your software to databases or ERP systems, like SAP or Oracle, to automate data input. If you’re printing shipping labels, integration pulls order details directly from your warehouse management system, eliminating manual data entry. NiceLabel’s automation module, for instance, can trigger printing based on inventory updates, saving hours in high-volume settings. Set up templates with dynamic fields, such as product names or expiration dates, to streamline batch printing.

Use Cloud-Based Solutions for Flexibility: Cloud-based software, like Loftware Cloud, lets you manage label designs across multiple locations, ensuring consistency and speed. If you operate several facilities, cloud access means your team can update designs instantly without emailing files. This is especially useful for businesses with seasonal products, as you can quickly adjust labels for promotions. Ensure your software supports your printer models to avoid compatibility issues.

By using efficient, professional software and optimizing your designs, you can reduce design and printing time, especially for complex or high-volume jobs. Regularly update your software to access the latest speed-enhancing features.

Implement Automation for High-Volume Printing

Automation is a game-changer for businesses printing large quantities of labels. By reducing manual tasks, you can handle high-volume printing with minimal delays. Here’s how to integrate automation into your workflow.

Automate Label Application: Manual label application is time-consuming, especially for thousands of products. Invest in automatic label applicators, like the TACH-IT SH-414D, which applies labels to flat or cylindrical surfaces at high speeds. These devices sync with your printer, dispensing and applying labels in one step. For example, a beverage company labeling 10,000 bottles daily can cut application time by hours with an applicator. Ensure the applicator is compatible with your label sizes and materials, such as custom thermal transfer labels.

Use Print-and-Apply Systems: For logistics or manufacturing, print-and-apply systems combine printing and application in a single machine. Models like the SATO CL4NX Plus print labels and apply them to boxes or pallets in seconds, ideal for shipping operations. These systems integrate with warehouse management software, automatically printing labels based on order data. You can buy thermal label printers online with print-and-apply capabilities to streamline your workflow.

Incorporate Label Counting and Rewinding: If you print labels in bulk for later use, manual counting and rolling is slow and error-prone. A label counter machine for sale, such as those available for industrial use, counts and rewinds labels automatically, ensuring accurate quantities. Rewinders, like the Primera AP550, roll printed labels neatly for storage or application, saving time compared to hand-rolling. These tools are essential for businesses printing over 5,000 labels per run, like food manufacturers or e-commerce warehouses.

Leverage Barcode Scanners for Verification: Printing errors, like incorrect barcodes, can halt production if not caught early. Use affordable barcode scanners online to verify labels as they print, ensuring accuracy without slowing down the process. Scanners like the Zebra DS2208 can scan barcodes in milliseconds, letting you catch errors before labels are applied. Integrate scanners with your software to log verification data, reducing manual checks.

Automation reduces human error and speeds up repetitive tasks, making it ideal for high-volume printing. Start with one or two automated tools, like applicators or counters, and scale up as your needs grow.

Optimize Your Workflow for Maximum Speed

Beyond printers, software, and automation, your overall workflow impacts printing speed. Small changes in how you manage materials, staff, and processes can save significant time. Here’s how to optimize your setup.

Streamline Material Management: Keep your label stock and consumables organized to avoid delays. Store rolls of blank inkjet labels for sale or thermal transfer labels for sale near your printer to minimize retrieval time. Use high-capacity label rolls to reduce reloading frequency—industrial printers like the Afinia L901 support rolls with thousands of labels. Similarly, stock up on consumables, like SATO printer ribbons or ink cartridges, to prevent pauses during printing. You can buy SATO printer ribbons online to ensure you’re always prepared.

Train Staff for Efficiency: Ensure your team knows how to operate printers and software effectively. Provide training on tasks like loading labels, changing ribbons, and troubleshooting common issues, such as paper jams. For example, a 30-minute training session on the Epson TM-C7500G can teach staff to swap ink cartridges in under a minute, reducing downtime. Create quick-reference guides for common tasks to keep production moving.

Schedule Maintenance to Avoid Disruptions: Regular printer maintenance prevents slowdowns from clogs or worn parts. Clean printheads weekly with thermal printer cleaning pens, which cost around $15 for a box of 12, to maintain print quality. Replace ribbons or cartridges before they run out, and check rollers for wear monthly. Schedule maintenance during off-hours to avoid interrupting production. For instance, cleaning a Zebra ZT411 takes 10 minutes and ensures consistent speed.

Batch Print Similar Jobs: Group similar printing tasks to minimize setup changes. If you’re printing labels for multiple products, print all labels requiring the same material, like premium topcoated direct thermal labels, in one batch. Switching between label types or sizes requires recalibrating the printer, which can take several minutes. Batching reduces these interruptions, especially for businesses with diverse product lines, like cosmetics or food brands.

By optimizing your workflow, you eliminate bottlenecks and keep your printing process running smoothly, even during peak demand.

Address Common Bottlenecks

Even with the best tools, bottlenecks can slow you down. Identify and fix these issues to maintain speed. If your printer is old, it may struggle with high volumes—upgrade to a high-quality thermal label printer for sale, like the GoDEX ZX1000, for faster output. If software crashes or lags, ensure your computer meets the program’s requirements, such as 8GB RAM for BarTender. For network-connected printers, use wired connections instead of Wi-Fi to avoid signal drops that delay print jobs.

If label jams are frequent, check that your labels are loaded correctly and match the printer’s specifications. For example, using non-topcoated direct thermal labels in an inkjet printer can cause jams. Finally, if your design process is slow, simplify templates or outsource complex designs to a professional service, freeing up time for printing.

Transform Your Label Printing Process

Slow label printing doesn’t have to hold your business back. By choosing faster printers, using efficient software, implementing automation, and optimizing your workflow, you can handle high-volume printing with ease. To get started, buy thermal label printers online, purchase blank inkjet labels online for vibrant designs, and invest in the best label design software for printers. For reliable supplies, check out custom thermal transfer labels and more at DuraFast Label Company to keep your production fast and efficient.