On-Demand Label Printing vs. Bulk Label Orders: Which Strategy Saves More Money?

23rd Jul 2025

When you're managing a product line with frequent design changes—like seasonal blends of coffee—on-demand printing lets you adapt without the cost of discarding outdated stock

Label printing is a critical part of your business, whether you’re labeling food products, pharmaceuticals, or shipping boxes. Choosing between on-demand in-house printing and outsourcing bulk label orders can significantly impact your bottom line. Each approach has unique cost implications, flexibility benefits, and operational advantages. This guide compares these strategies in depth to help you decide which saves more money for your business.

Cost-Effectiveness: Breaking Down the Numbers

When deciding between on-demand label printing and bulk label orders, cost is often your top concern. Both approaches have different expense structures, and understanding these helps you make an informed choice. Here’s a detailed look at the cost factors for each method.

On-Demand In-House Printing Costs

On-demand printing means producing labels as needed using your own equipment, such as thermal transfer or inkjet printers. This approach requires an upfront investment but offers long-term savings in certain scenarios.

Initial Equipment Investment: To print labels in-house, you need a label printer, which varies in price based on your needs. For small businesses printing a few hundred labels daily, a desktop printer like the Primera LX910 costs around $2,500 and prints vibrant color labels at 4.5 inches per second. For high-volume operations, like a warehouse printing thousands of shipping labels, an industrial printer like the Zebra ZT610, priced at $3,000-$5,000, handles speeds up to 14 inches per second. You can buy thermal label printers online to find models that match your volume. Additional equipment, like label rewinders or applicators, may add $500-$2,000 to your setup.

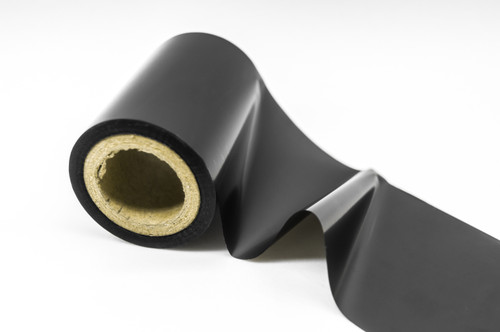

Consumables and Supplies: Ongoing costs include labels, ink, and ribbons. For example, a roll of 1,000 4x6-inch thermal transfer labels for sale costs about $15-$25, depending on material (paper or synthetic). Ink cartridges for inkjet printers, like the Epson ColorWorks C6000, cost $50-$100 per set, printing thousands of labels before replacement. Thermal transfer ribbons, such as those for the Zebra ZT610, cost $10-$30 per roll. You can buy Zebra ribbons online to keep costs predictable. Maintenance supplies, like thermal printer cleaning pens, add minimal costs, around $15 for a box of 12.

Labor Costs: In-house printing requires staff to operate and maintain printers. For a small business, one employee might spend an hour daily on printing and application, costing $15-$25 per hour based on average U.S. wages. Larger operations may need dedicated staff, increasing labor costs. Training staff to use printers and software, like BarTender, takes a few hours initially but reduces errors and speeds up workflows over time.

Per-Label Cost Analysis: The per-label cost for on-demand printing depends on volume and materials. For a small run of 500 color labels using an inkjet printer, you might spend $0.10-$0.20 per label, including ink and label stock. For high volumes, like 10,000 labels on a thermal transfer printer, costs drop to $0.05-$0.10 per label due to economies of scale. These costs are higher than bulk orders for large runs but competitive for small batches, as you avoid setup fees charged by print houses.

Long-Term Savings: On-demand printing shines for businesses with frequent label changes or small runs. If you’re a craft brewery releasing seasonal beers, printing 500 labels per batch in-house avoids the high minimum order quantities (MOQs) of bulk printing, which often start at 5,000 labels. You also save on storage costs, as you print only what you need, reducing waste from obsolete labels. If your product details change—like updating an ingredient list—you can revise designs instantly without paying for new plates or discarding unused stock.

Bulk Label Order Costs

Bulk label orders involve outsourcing production to a third-party print house, which prints large quantities at once, typically using flexographic or offset printing. This method is cost-effective for high volumes but has limitations.

Setup and Plate Costs: Print houses charge setup fees for creating printing plates, which range from $200-$1,000 per design, depending on complexity and color count. If you’re printing labels for a single product, this is a one-time cost. However, if you need multiple designs or frequent updates, like a cosmetics brand with 10 product variants, you’ll pay setup fees for each, significantly increasing costs. Some printers waive setup fees for very large orders, but MOQs are often 5,000-10,000 labels.

Per-Label Cost: Bulk printing is cheaper per label for large runs. For 10,000 4x6-inch color labels, you might pay $0.02-$0.05 per label, including materials and printing. For 50,000 labels, costs can drop to $0.01-$0.03 per label. These prices are lower than on-demand printing for high volumes, but less economical for small runs, as setup fees inflate costs. For example, 500 labels might cost $0.50-$1.00 each due to fixed setup charges, making bulk orders impractical for low quantities.

Shipping and Storage Costs: Outsourcing means paying for shipping, which can add $50-$200 per order, depending on weight and distance. You also need space to store thousands of labels, which may require shelving or warehouse space, costing $100-$500 monthly for small businesses. If you’re a food manufacturer with limited storage, this adds up quickly. Labels must be stored in climate-controlled conditions to prevent adhesive degradation, adding to expenses.

Lead Time Costs: Bulk orders take time—typically 1-3 weeks for production and delivery. If you need labels urgently, rush fees can double costs. For example, a last-minute order for a product launch might cost $2,000 instead of $1,000. Delays in delivery can also halt production or shipping, leading to lost sales or customer dissatisfaction. In-house printing avoids these delays, as you print labels on the spot.

Waste and Obsolescence: Bulk orders carry the risk of waste if your needs change. If you order 20,000 labels but a regulation requires new warnings, you may need to discard unused stock, losing hundreds or thousands of dollars. Similarly, if a product underperforms, excess labels become obsolete. This is a major drawback for businesses with dynamic product lines, like seasonal goods or limited-edition items.

Cost Comparison Summary

For small runs (under 5,000 labels), on-demand printing is more cost-effective, as you avoid setup fees and MOQs. A 500-label run might cost $50-$100 in-house versus $250-$500 for bulk orders. For large runs (over 10,000 labels), bulk printing is cheaper per label, but total costs depend on setup, shipping, and storage. If you print 50,000 labels, bulk orders might save $500-$1,000 compared to in-house, but only if you use all labels and have storage space. On-demand printing offers savings through flexibility and reduced waste, especially for businesses with frequent changes or low volumes.

Initial Setup Costs: Upfront Investment vs. Outsourcing Fees

The initial costs of each method shape your long-term savings. Here’s a detailed breakdown of what you’ll spend to get started.

On-Demand Printing Setup

Setting up an in-house printing operation requires investment in equipment, software, and training, but these costs are one-time or spread over time.

Printer Purchase or Lease: As mentioned, desktop printers cost $1,500-$3,000, while industrial models range from $3,000-$10,000. You can buy thermal transfer printers or inkjet models online, depending on your needs. Leasing is an option to reduce upfront costs—many suppliers offer printers for $50-$200 per month, spreading payments over 2-3 years. For example, leasing a Zebra ZT411 for $100 monthly makes high-volume printing accessible for small businesses.

Software Investment: Professional label design software, like NiceLabel or BarTender, costs $200-$1,000 for a single license, depending on features. You can buy barcode printing software online to streamline design and printing. Cloud-based options, like Loftware Cloud, have subscription fees of $50-$200 monthly, offering flexibility for multi-site operations. Free software, like ZebraDesigner, is available for basic needs but lacks advanced features like database integration.

Accessories and Infrastructure: You may need accessories like label rewinders ($300-$1,000), applicators ($500-$2,000), or a label counter machine for sale ($1,000-$3,000) to handle bulk printing. Basic infrastructure, like a dedicated computer and workspace, adds $500-$1,500. Ensure your setup includes reliable power and network connections to avoid disruptions.

Training and Setup Time: Training staff to use printers and software takes 2-10 hours, depending on complexity. For example, learning BarTender’s variable data printing features might take a day, but it saves time long-term. Initial setup, including installing printers and calibrating for label stock, takes a few hours. Suppliers often provide free tutorials or support to speed this up.

Total Initial Cost: For a small business, expect to spend $2,500-$5,000 on a desktop printer, software, and basic accessories. For industrial setups, costs range from $5,000-$15,000. Leasing and free training can lower this to $1,000-$2,000 upfront, making on-demand printing feasible for startups.

Bulk Printing Setup

Outsourcing bulk orders requires minimal upfront investment, as you rely on the print house’s equipment. However, setup fees and order commitments create their own costs.

Design and Plate Fees: Each label design requires a printing plate, costing $200-$1,000 per design. If you have multiple products, like a skincare line with 10 variants, you could spend $2,000-$10,000 on plates. Some print houses offer digital printing for small runs, reducing plate costs, but these are still higher than in-house digital printing. If you need frequent design changes, you’ll pay for new plates each time.

Minimum Order Commitments: Print houses often require MOQs of 5,000-10,000 labels per design. For a small business, committing to $500-$2,000 per order is a significant upfront cost, especially if you don’t need all the labels immediately. Negotiating lower MOQs is possible for repeat customers, but it raises per-label costs.

Proofing and Testing: Before printing, you’ll need to review proofs, which may cost $50-$200 per design for physical samples. Testing labels on your products, especially for adhesion or durability, adds time and shipping costs. If revisions are needed, additional fees apply, delaying production.

Total Initial Cost: For bulk printing, expect to spend $500-$5,000 per order, depending on design complexity and MOQs. Unlike on-demand printing, these costs recur with each order, especially for new designs or changes. You avoid equipment costs but face ongoing fees that add up over time.

Setup Cost Comparison

On-demand printing requires a higher initial investment ($2,500-$15,000) but eliminates recurring setup fees. After setup, your costs are limited to consumables and labor. Bulk printing has lower upfront costs ($500-$5,000 per order), but recurring fees for plates, proofs, and MOQs make it less economical for frequent orders or small runs. If you print fewer than 5,000 labels per design or need regular updates, on-demand printing saves more money long-term.

Material Costs: Labels, Inks, and Ribbons

Material costs are a major factor in both methods, as they directly affect your per-label expenses. Here’s how on-demand and bulk printing compare.

On-Demand Material Costs

With in-house printing, you control material choices, which impact costs and flexibility.

Label Stock: You can choose from paper, synthetic, or specialty labels, like premium topcoated direct thermal labels or blank inkjet labels for sale. Paper labels cost $10-$20 per roll of 1,000, while synthetics, like BOPP for chemical labels, cost $20-$50 per roll. Buying in bulk reduces costs—purchasing 10 rolls at once might save 10-20%. You can buy blank inkjet labels online to match your printer, ensuring compatibility.

Inks and Ribbons: Inkjet printers require cartridges, costing $50-$100 per set. For example, a set for the Epson TM-C7500G prints 10,000-20,000 labels, depending on coverage. Thermal transfer printers use ribbons, like wax-resin or resin, costing $10-$30 per roll for 1,000-2,000 labels. You can order Datamax ribbons online for industrial printers to keep costs low. Pigment-based inks are pricier but necessary for durable labels in food or pharmaceutical applications.

Maintenance Supplies: Regular maintenance keeps costs down by preventing printer failures. Cleaning kits, like thermal printer cleaning pens, cost $15-$30 and last for months. Replacement parts, like printheads, cost $100-$500 but are rarely needed with proper care. Stocking up on supplies ensures uninterrupted printing.

Cost Control: On-demand printing lets you buy materials as needed, avoiding overstocking. If you’re printing 1,000 labels weekly, you might spend $20 on labels and $5 on ink or ribbons, totaling $25. For 10,000 labels, costs scale to $150-$200, but you only buy what you use, reducing waste. Testing different materials, like non-topcoated direct thermal labels for short-term use, helps you find the cheapest options for your needs.

Bulk Printing Material Costs

With bulk orders, the print house handles materials, but you have less control over choices and costs.

Label Stock: Print houses offer similar materials—paper, BOPP, or polyester—but prices are baked into the per-label cost. For 10,000 paper labels, you might pay $0.03 per label ($300 total), including materials. Synthetics cost more, around $0.05-$0.10 per label. You can request specific materials, like BS 5609-compliant labels for chemicals, but customizations raise prices. Unlike in-house printing, you can’t buy materials separately to save money.

Inks and Printing: Bulk printing uses flexographic or offset inks, included in the order cost. You don’t pay separately for inks, but you can’t choose between dye-based or pigment-based options, which affects durability. If you need UV-resistant labels, you’ll pay a premium, adding $0.01-$0.02 per label. Print houses prioritize cost-effective inks, which may not suit specialized needs, like pharmaceutical labels requiring fade resistance.

Additional Fees: Some print houses charge extra for finishes, like laminates or UV coatings, adding $0.01-$0.05 per label. Rush orders or special materials, like holographic labels, can increase costs by 20-50%. These fees are less transparent than in-house material costs, making budgeting harder.

Cost Control Challenges: Bulk printing locks you into large orders, so you can’t adjust material quantities dynamically. If you order 20,000 labels but only use 10,000, you’ve spent $200-$500 on unused stock. You also rely on the print house’s material quality, which may not match your expectations, leading to reprints or quality issues.

Material Cost Comparison

On-demand printing gives you control over material costs, letting you buy labels and inks as needed, with rolls costing $10-$50 and consumables $5-$100. For 1,000 labels, you might spend $25-$50 in-house versus $50-$100 for bulk orders, including setup fees. For 50,000 labels, bulk printing is cheaper at $500-$1,500 versus $1,000-$2,000 in-house, but only if you use all labels. On-demand printing saves money for small runs or businesses with variable needs, as you avoid waste and overstocking.

Flexibility: Adapting to Changing Needs

Flexibility is a key factor when choosing between on-demand printing and bulk orders. Your ability to adapt to design changes, market demands, or regulatory updates can impact costs and efficiency. Here’s how each method compares.

On-Demand Printing Flexibility

On-demand printing gives you control over when and how you produce labels, making it ideal for businesses with dynamic or unpredictable needs.

Rapid Design Changes: With in-house printing, you can update label designs instantly using software like BarTender or NiceLabel, which you can buy as barcode printing software online. If you’re a food manufacturer and need to add a new allergen warning due to a recipe change, you can revise the design and print updated labels within hours. This avoids the $200-$1,000 plate fees charged by print houses for design changes. For example, a bakery printing 1,000 labels for a new cookie flavor can tweak nutritional info or branding without extra costs, saving money and time.

Small Batch Printing: On-demand printing excels for small runs, as you’re not tied to minimum order quantities (MOQs). If you’re a cosmetics brand launching a limited-edition lip balm, you can print 500 labels to test the market, costing $50-$100 for materials like blank inkjet labels for sale. Bulk orders often require 5,000-10,000 labels, costing $250-$500, even if you only need a fraction. This flexibility prevents overstocking and reduces waste, especially for seasonal or promotional products like holiday-themed beverages.

Variable Data Printing: In-house printers support variable data printing, allowing you to print unique labels in a single run. For instance, a winery can print 1,000 labels with individual QR codes linking to customer-specific promotions, all without additional setup. This is perfect for personalized marketing or compliance needs, like serial numbers on electronics. Bulk printing requires separate plates for each variation, adding $200-$500 per design, making it cost-prohibitive for customized labels.

Material and Finish Options: You can experiment with different label materials, such as premium topcoated direct thermal labels or custom thermal transfer labels, to match your product’s needs. If you’re labeling chemical drums, you can test BS 5609-compliant synthetic labels for durability, then switch to paper labels for a different product, all with the same printer. Print houses may charge extra for material changes or limit options, reducing your ability to adapt quickly.

Market Responsiveness: On-demand printing lets you respond to market trends or customer feedback instantly. If you’re a snack brand and notice demand for a new flavor, you can print labels for a small batch within a day, getting the product to market faster. Bulk orders take 1-3 weeks for delivery, delaying launches and potentially missing sales opportunities. This speed saves money by capitalizing on trends without committing to large, risky orders.

Bulk Printing Flexibility

Bulk printing is less flexible, as it’s designed for large, static orders, but it can work for businesses with consistent, high-volume needs.

Limited Design Updates: Changing a label design with bulk printing is expensive and slow. If you need to update a barcode or ingredient list, you’ll pay $200-$1,000 for new plates and wait 1-2 weeks for production. For businesses with stable designs, like a detergent brand with unchanging packaging, this isn’t a major issue. However, if you frequently tweak designs, like a craft brewery with monthly specials, these costs add up, making bulk printing less economical.

High MOQs: Print houses enforce MOQs of 5,000-10,000 labels, limiting your ability to print small batches. If you’re testing a new product, you’re forced to order more labels than needed, risking waste if the product fails. For example, a small retailer ordering 5,000 labels for a trial product might spend $300, only to use 1,000, wasting $240. On-demand printing avoids this by letting you print exactly what you need.

Fixed Materials and Finishes: Bulk orders lock you into specific materials and finishes for the entire run. If you order 20,000 paper labels but later need synthetic ones for a waterproof product, you’ll need a new order, incurring setup and shipping costs. In-house printing lets you switch materials on the fly, using the same printer for paper, BOPP, or polyester labels, saving money on redundant orders.

Delayed Market Response: The long lead times of bulk printing—1-3 weeks—make it hard to adapt to sudden changes. If a competitor launches a new product or a regulation shifts, you can’t pivot quickly, potentially losing market share. Rush orders are possible but cost 20-50% more, negating savings. For instance, expediting 10,000 labels might add $200-$500 to your order, compared to printing in-house at no extra cost.

Flexibility Comparison

On-demand printing offers superior flexibility, allowing you to print small batches, update designs instantly, and adapt to market or regulatory changes without extra fees. This saves money for businesses with variable needs, like seasonal products or frequent rebranding. Bulk printing is less flexible, with high MOQs, costly design changes, and long lead times, but it suits businesses with stable, high-volume demands, like mass-produced goods. If flexibility is a priority, on-demand printing is the cost-effective choice, as it minimizes waste and delays.

Operational Advantages: Streamlining Your Workflow

Operational efficiency affects your overall costs, as downtime, labor, and errors can erode savings. Here’s how on-demand and bulk printing impact your workflow.

On-Demand Printing Operational Advantages

In-house printing streamlines operations by giving you control over the entire process, from design to application.

Immediate Production: With on-demand printing, you produce labels as needed, eliminating wait times. If you’re a logistics company and receive a last-minute order for 2,000 shipping labels, you can print them in hours using a printer like the SATO CL4NX Plus. Bulk orders take weeks, delaying shipments and risking customer dissatisfaction. This speed reduces operational bottlenecks, saving money on expedited orders or lost sales.

In-House Control: Printing in-house lets you monitor quality and catch errors before labels are applied. If a barcode prints incorrectly, you can stop the job, fix the design, and reprint without wasting thousands of labels. Bulk printing relies on the print house’s quality control, and errors may not be caught until delivery, requiring costly reprints. For example, a misprinted batch of 10,000 labels could cost $500 to replace, plus shipping.

Automation Integration: On-demand printers integrate with automation tools, like label applicators or print-and-apply systems, to speed up workflows. A device like the TACH-IT SH-414D applies labels to 100 bottles per minute, reducing labor time. You can also use a label counter machine for sale to count and rewind labels, ensuring accurate quantities for large runs. These tools minimize manual tasks, saving hours daily in high-volume settings like food production.

Reduced Storage Needs: Printing only what you need eliminates the need for large storage spaces. If you’re a small retailer, you can store a few rolls of thermal transfer labels for sale in a desk drawer, costing nothing extra. Bulk orders require shelving or warehouse space, which can cost $100-$500 monthly. This space-saving is critical for businesses with limited facilities, reducing overhead costs.

Scalability: On-demand printing scales with your business. If you start with a desktop printer and later need more capacity, you can upgrade to an industrial model or add a second unit. For example, adding a Zebra ZT411 for $3,000 doubles your output without changing workflows. Bulk printing requires larger orders to maintain low per-label costs, which can strain cash flow for growing businesses.

Bulk Printing Operational Advantages

Bulk printing shifts operational responsibilities to the print house, which can simplify workflows but introduces dependencies.

Minimal In-House Effort: Outsourcing eliminates the need for in-house printing equipment or expertise. You send designs to the print house, review proofs, and receive finished labels, freeing up staff for other tasks. For a small business with limited resources, this reduces labor costs, as you don’t need to train employees on printers or software. However, you still need staff to manage orders and inventory, which may offset some savings.

High-Volume Efficiency: For large, consistent runs, bulk printing is operationally efficient. If you’re a detergent manufacturer producing 100,000 identical labels monthly, the print house’s high-speed flexographic presses churn them out quickly, delivering in 1-2 weeks. In-house printing might require multiple printers or shifts to match this volume, increasing labor and maintenance costs.

Quality Consistency: Print houses use industrial-grade equipment, ensuring consistent quality across large runs. If you need 50,000 labels with precise color matching, like Pantone shades for branding, bulk printing delivers uniformity. In-house printers, especially entry-level models, may have slight variations in color or alignment over long runs, requiring adjustments. However, high-quality color label printers for sale, like the Epson TM-C7500G, rival professional quality for most applications.

Dependency on Suppliers: Bulk printing makes you reliant on the print house’s schedule and reliability. Delays due to equipment issues or shipping problems can halt your operations. For example, a late delivery of 20,000 labels might delay a product launch, costing thousands in lost sales. In-house printing avoids this risk, as you control production.

Operational Advantages Comparison

On-demand printing offers operational advantages through immediate production, in-house control, and automation, saving time and reducing errors. It’s ideal for businesses needing quick turnarounds or small batches, like e-commerce or seasonal goods. Bulk printing simplifies workflows for high-volume, static needs but introduces dependencies and delays, which can increase costs if issues arise. For most businesses, on-demand printing’s operational flexibility translates to cost savings by minimizing downtime and waste.

Choose the Strategy That Saves You Most

Choosing between on-demand label printing and bulk orders depends on your volume, flexibility needs, and industry. On-demand printing saves money for small runs, frequent changes, or dynamic markets, offering control and speed. Bulk printing is cost-effective for large, stable runs but risks waste and delays. To start printing in-house, purchase color label printers online, buy blank inkjet labels online for vibrant designs, and invest in the best label design software for printers. For durable supplies, check out thermal transfer labels for sale at DuraFast Label Company to optimize your labeling and save money.