Why Is Electrical Panel Labeling Important for Safety?

9th Feb 2026

Key Highlights

- Electrical panel labeling ensures quick identification during repairs and emergencies.

- Proper labeling protects against electrical hazards and helps meet safety standards.

- Include circuit ID, voltage, current ratings, and safety warnings for clarity.

- Use durable, UV-resistant materials to prevent fading and ensure long-lasting labels.

- Regularly inspect labels and update them as needed for safety and compliance.

- NEC, OSHA, and NFPA standards govern electrical panel labeling requirements.

- Reliable label printers and materials ensure professional, clear, and compliant labeling.

- Keep a digital backup of circuit information for easy future reference.

Ever opened your breaker box and had no idea which switch controls what? You’re not alone. A clear electrical panel label can save you a ton of time, frustration, and even help prevent safety hazards. Whether you’re a homeowner trying to stay organized or an electrician keeping up with standards, proper electrical panel labeling makes all the difference.

In this guide, we’ll break down how to label your panel the right way, step by step. From choosing the best materials to following essential safety rules, you’ll learn how a simple electrical panel label can turn a confusing mess of circuits into a clean, easy-to-understand system.

Let’s make your electrical panel labeling clear, compliant, and stress-free!

What Is Electrical Panel Labeling?

Electrical panel labeling refers to the practice of clearly marking the various circuits and components within an electrical panel to ensure easy identification and safe operation. It involves labeling breakers, circuit connections, and other key elements to make maintenance, troubleshooting, and emergency responses more efficient.

Proper labeling helps prevent confusion, reduces the risk of electrical accidents, and ensures compliance with safety codes such as NEC, OSHA, and NFPA. By marking each circuit with specific details like the area it powers, its voltage, and current ratings, anyone working on the system can quickly understand its configuration and avoid costly or dangerous mistakes.

Electrical panel labeling is not only crucial for safety, but it also promotes organization, ensures faster repairs, and guarantees that the electrical system meets required safety standards.

Why Electrical Panel Labeling Matters?

Most people don’t think twice about their breaker box until something goes wrong. The truth is, electrical panel labeling is what keeps chaos (and danger) out of your wiring system. When circuits are clearly marked, you can shut off the right breaker in seconds during repairs or emergencies, no guessing, no panic.

Accurate electrical panel breaker labels and circuit labels do more than provide convenience; they safeguard your property and ensure safety. Proper labeling helps electricians work efficiently, reducing costly mistakes. Additionally, following electrical panel labeling standards and meeting electrical panel label requirements ensures compliance with safety codes.

Whether you use a simple electrical panel label maker or go for engraved labels for electrical panels, proper electrical panel board labeling and electrical panel identification labels ensure your system stays clear, safe, and easy to navigate.

In short, labeling your panel isn’t about looks; it’s about making sure everyone knows exactly what they’re dealing with when it matters most.

What Information Should Be Included on an Electrical Panel Label?

When it comes to electrical labeling, the goal is simple: make everything clear, safe, and easy to understand. Whether you’re working on a home setup or complex electrical systems in industrial settings, proper labeling ensures everyone knows what’s what inside the breaker panel.

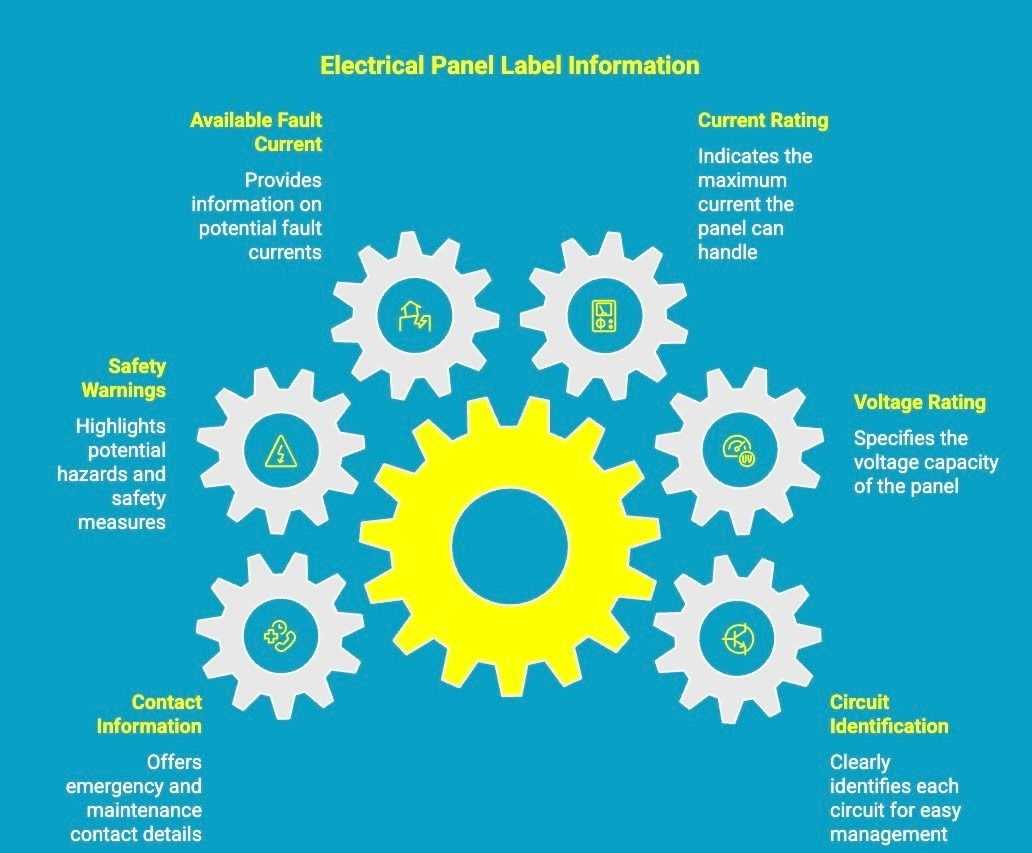

Here’s what every electrical panel label should include:

1. Circuit Identification

Each circuit breaker needs a clear ID so anyone can match it to the right area or equipment. Use alphanumeric codes or short descriptions to help you find the correct breaker quickly, no more guessing which one powers the kitchen or office lights.

2. Voltage Rating

Including the voltage helps prevent overloads and electrical hazards. It’s crucial for electrical installations across commercial properties and industrial settings, where multiple power supply levels may exist.

3. Current Rating

Marking the current rating ensures safe handling of electrical components and helps prevent electrical issues or tripped breakers.

4. Available Fault Current Details

This info is essential for master electricians and technicians. It tells them how much current could flow during a fault, vital for meeting NEC standards and National Fire Protection Association (NFPA) safety standards.

5. Safety and Hazard Warnings

Include safety signs and warnings about potential hazards, electric shock, or electrical shocks. These alerts protect everyone and align with the Occupational Safety and Health Administration (OSHA) specific guidelines for electrical equipment.

6. Emergency or Maintenance Contact Information

A good label also includes who to call in an emergency, your master electrician or maintenance team, so issues can be resolved fast and safely.

For the labeling process, use a durable label printer or sticky labels made to withstand harsh conditions. Mount labels neatly on the panel door for clear labeling that lasts.

In short, good labeling is more than a checklist, it’s a systematic approach to keeping your electrical applications safe, organized, and ready for future maintenance. It’s all about ensuring the flow of electricity stays smooth while keeping people safe from harm.

What Are the Key Standards and Requirements for Labeling Electrical Panels?

Labeling an electrical panel isn’t just about being organized; it’s about staying safe and compliant. Whether you’re a homeowner, facility manager, or master electrician, following key safety standards ensures your electrical systems meet national regulations and help prevent serious electrical hazards.

Let’s break down the main ones you should know.

1. NEC (National Electrical Code) Labeling Requirements

To ensure safety and compliance, the NEC outlines key labeling requirements for electrical installations. Here’s what you need to know:

- NEC Standards Overview: The NEC standards, developed by the National Fire Protection Association (NFPA), provide the foundation for safe electrical installations across the U.S.

- Labeling Requirements: The NEC mandates proper labeling on electrical panels, circuits, and equipment to identify their function, voltage, and potential risks.

- Specific Labeling Mandates: The code requires clear labeling for critical components such as the main breaker, available fault current, and disconnects.

- Benefits of NEC Labeling: Proper labeling ensures that anyone working on the electrical system, now or during future maintenance, can easily identify and manage the risks before touching any equipment.

By following NEC guidelines, you enhance safety and ensure that your electrical systems are clearly understood by all professionals.

2. OSHA Labeling Requirements for Electrical Safety

The Occupational Safety and Health Administration (OSHA) focuses on protecting workers from electrical hazards like electric shock, arc flash, and short circuits. To ensure safety, OSHA provides specific labeling requirements:

- Durable Safety Signs and Labels: Ensure labels are made from durable materials to withstand harsh conditions.

- Visibility: Labels must be clearly visible and easy to read from a distance.

- Warning Labels: Use clear and concise warning labels for electrical hazards like shock, arc flash, and short circuits.

- Hazard Markings: Mark areas with hazard-specific signs such as high voltage warnings and arc flash boundaries.

- Proper Placement: Labels should be placed in accessible, visible locations for workers to easily identify potential electrical risks.

- Legibility in Harsh Environments: Labels should remain legible under extreme conditions, such as exposure to chemicals, moisture, or heat.

By adhering to these OSHA guidelines, you ensure a safer work environment for anyone interacting with electrical systems.

3. NFPA Labeling Guidelines and Best Practices

The National Fire Protection Association (NFPA) provides specific guidelines to improve safety and reduce risks of fire and shock. These include labeling voltage levels, identifying arc flash boundaries, and marking emergency shutdown points clearly. NFPA standards also recommend using color codes for hazard identification and ensuring all labels are placed in visible, accessible locations.

By following these best practices, you ensure that electrical panels and components are consistently labeled, reducing the risk of errors during maintenance and troubleshooting.These standards go beyond compliance; they protect people. Following NEC, OSHA, and NFPA rules ensures safety and creates a secure environment for anyone interacting with your electrical systems.

How to Label Electrical Panel?

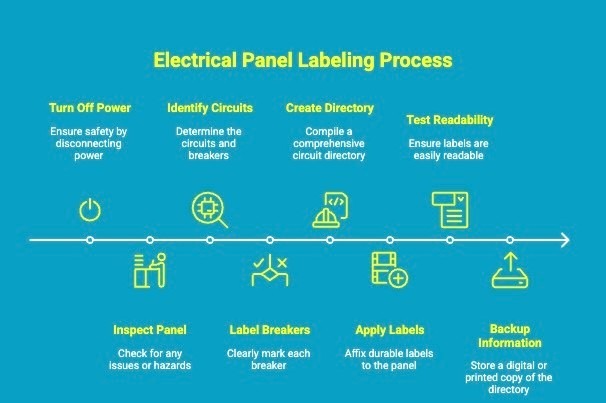

Alt Text: Infographic showcasing steps to label electrical panel

Labeling your electrical panel might seem like a quick weekend task, but when done right, it can make your electrical systems safer, more compliant, and way easier to maintain. Let’s break it down step by step, with a focus on the tools and label printers that’ll make the job look clean and professional.

Step 1: Turn Off Power and Inspect the Panel

Always start by flipping off the main breaker for safety. Inspect the panel for rust, debris, or old labels that need replacing. Ensure there are no loose components.

Step 2: Identify Circuits and Breakers

Flip each circuit breaker and check which lights, outlets, or appliances turn off. Write down what each breaker controls. For complex setups, use alphanumeric codes for clarity.

Step 3: Label Your Breakers

Use a durable label printer to clearly mark each breaker with its function. Include voltage, current, and any necessary safety warnings. This ensures clear identification and meets safety codes.

Step 4: Create a Clear Circuit Directory

Inside the panel door, add a printed directory listing each breaker’s purpose. Include details such as room, equipment name, and voltage. Laminate for added durability and easy readability.

Step 5: Apply Durable Labels and Test Readability

Apply the printed labels neatly on each breaker. Smooth them down to avoid air bubbles and test each one by flipping breakers to ensure they match the correct circuit.

Step 6: Keep a Digital Backup or Printed Reference

Take photos of the labeled panel and store them digitally or in a maintenance log. This ensures quick reference in case labels wear out or need updating.

What Are the Right Tools for Electrical Panel Labeling?

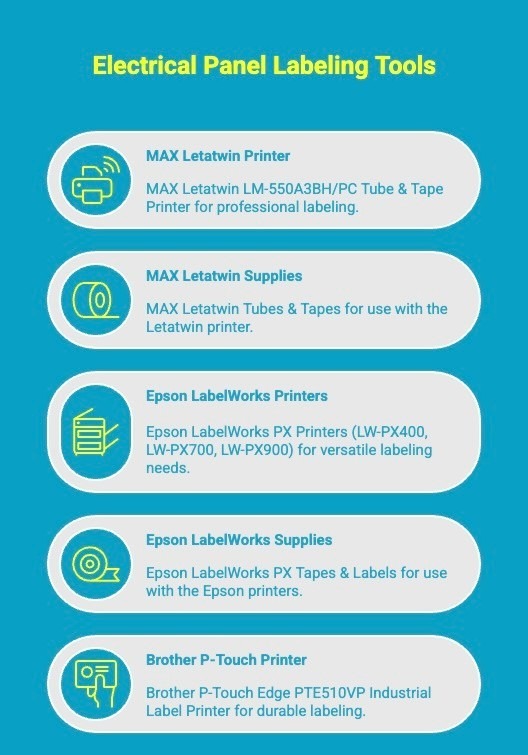

Choosing the right tools makes the job easier and ensures durability. Here are some recommended label printers for professional results:

1. MAX Letatwin LM-550A3BH/PC Tube & Tape Printer

The MAX Letatwin LM-550A3BH/PC is a professional tube and tape printer designed specifically for electrical environments where wire identification must be long-lasting and easy to read. It prints quickly on heat-shrink tubing and adhesive tapes, making it ideal for labeling panel wiring, terminal blocks, and circuit groups. Its precision print quality ensures that wire markers remain legible even in tight, high-heat environments.

2. MAX Letatwin Tubes & Tapes

Genuine Letatwin tubes and tapes are made for durability, heat resistance, and strong adhesion, three essential qualities for electrical panel labeling. These consumables are engineered to fit Letatwin printers perfectly, ensuring smooth feeding, clear printing, and long-term readability on wires, cables, and components.

3. Epson LabelWorks PX Printers (LW-PX400, LW-PX700, LW-PX900)

The Epson LabelWorks PX series combines rugged industrial design with portable convenience, making them ideal for electricians who need reliable labeling on job sites. These printers support heat-shrink tube printing, strong adhesive tapes, and specialty industrial materials. With fast print speeds, mobile connectivity, and compact durability, the PX series helps create clear, standardized labels for breakers, wiring, panel doors, and equipment tags.

4. Epson LabelWorks PX Tapes & Labels

PX-series tapes are engineered for harsh environments, resisting chemicals, UV exposure, oil, moisture, and abrasion. They are perfect for labeling electrical panels because they maintain readability even in demanding conditions such as mechanical rooms, outdoor enclosures, or industrial plants. These tapes bond strongly to metal, plastic, and textured surfaces, ensuring your circuit and breaker labels stay put over time.

5. Brother P-Touch Edge PTE510VP Industrial Label Printer

The Brother P-Touch Edge PTE510VP is built for field electricians who need dependable labeling on the go. It supports up to 24mm industrial-grade tapes and features smart automatic cutting, making repetitive labeling tasks faster and more efficient. Its crisp thermal print technology produces clear component, breaker, and wire labels that remain legible over the long term.

How Can You Keep Electrical Panel Labels Clear and Long-Lasting?

Alt Text: Infographic showcasing electrical panel labels clear and long lasting

Keeping your electrical panel labels readable and durable isn’t just about neatness; it’s about safety and avoiding headaches during future maintenance. Here’s how to make sure your labeling stays effective over time.

1. Choose Durable, UV-Resistant, and Waterproof Label Materials

Cheap paper or tape might work for a day, but in harsh conditions like garages, basements, or industrial settings, they’ll fade, peel, or smudge fast. Use UV-resistant, waterproof, and oil-resistant materials, especially if you’re using a label printer. Materials like vinyl, polyester, or laminated labels can survive heat, moisture, and dust, keeping your breaker numbers and circuit information readable for years.

2. Inspect and Refresh Panel Labels Regularly

Make it a habit to check your panel labels during routine maintenance or electrical inspections. Look for peeling, fading, or smudged text. If a label isn’t clear, replace it immediately; it’s a small step that prevents big confusion or mistakes later. A quick glance every few months can save you from guessing which breaker controls which circuit when the power trips.

3. Store Updated Circuit Information in Digital and Physical Backups

Keep a digital copy of your circuit directory, like a photo or spreadsheet, and a printed backup tucked near the panel door or in your home maintenance folder. That way, even if a label wears out, you’ll have a reference ready to identify the correct breaker and avoid potential electrical hazards quickly.

By using durable materials, regularly inspecting your labels, and keeping digital and physical backups, your electrical panel labeling stays clear, safe, and reliable, making maintenance easier and protecting everyone from electrical shocks or hazards.

Durafast Label: Your Trusted Partner for High-Performance Printing and Labeling

For industrial‑grade labeling that lasts, DuraFast Label is the go-to choice. Their high-quality materials and compatible printers deliver clear, long-lasting labels that withstand heat, moisture, and harsh conditions, perfect for electrical panels, wiring, and industrial equipment.

With DuraFast Label, you get:

- Durable, professional labels that stay legible for years

- Compatibility with top label printers for sharp, precise printing

- Materials built for harsh environments, no fading, peeling, or smudging

Ensure your electrical panels and equipment stay safe, organized, and compliant. Contact us now to find the perfect labeling solution for your needs and elevate your labeling standards!

Final Thoughts

Proper electrical panel labeling is more than organization; it’s safety, efficiency, and compliance rolled into one. With the right label printer, durable materials, and adherence to NEC, OSHA, and NFPA standards, your panels remain clear, reliable, and easy to maintain for years. Investing a little more time in choosing the right labeling materials, tools, and ensuring proper adherence to safety standards will pay off in the long run by keeping your electrical panel organized, safe, and compliant with regulations. This effort helps prevent confusion, costly mistakes, and potential hazards during future maintenance or emergencies.

Frequently Asked Questions

What is the best way to label my electrical panel?

Use a durable label printer with UV-resistant or waterproof materials. Mark circuits clearly with alphanumeric codes and include voltage, current, and safety warnings to ensure clear identification, compliance with safety codes, and long-lasting readability.

What are the labeling requirements for electrical panels?

Labels must include circuit identification, voltage and current ratings, safety warnings, fault current information, and emergency contacts. This ensures compliance with NEC, OSHA, and NFPA standards while keeping the electrical system safe and easy to navigate.

What are the NEC requirements for labeling?

NEC requires clear identification of each breaker, main disconnects, and fault current details. These labels ensure safety during maintenance or repairs by providing essential information to anyone working on the electrical panel or system.

What are the OSHA 1910 requirements for electrical panel labeling?

OSHA 1910 requires visible hazard warnings, safety signs, and durable labels to prevent risks like electric shocks, arc flashes, and other workplace electrical hazards. These labels should be easy to read in all work environments.

How often should I update labels on my electrical panel?

Inspect your labels every few months for fading, peeling, or damage. Update them when new circuits are added or if labels become unreadable. Consistent maintenance ensures clear labeling for safety, compliance, and effective system operation.

What are common mistakes to avoid when labeling an electrical panel?

Avoid using handwritten labels, leaving out voltage information, or using inconsistent naming conventions. Poor labeling can cause confusion, electrical hazards, and safety code violations, putting your electrical system and people at risk.

Do I need special labels for commercial electrical panels compared to residential ones?

Yes, commercial panels often deal with harsher environments and higher voltages. Use durable, industrial-grade labels that comply with safety codes to ensure long-lasting legibility and protection in these demanding settings.