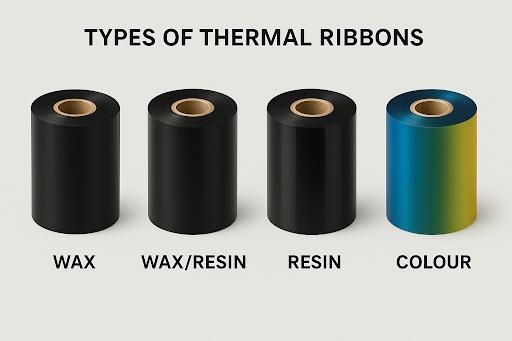

Types of Thermal Ribbons: Wax, Wax/Resin, Resin – Which One Should You Choose?

5th Sep 2025

If you’ve ever wondered what makes printed labels last longer, the answer often comes down to the types of thermal ribbons used in the process. Choosing the right ribbon ensures your labels are sharp, durable, and suited for the job. But with options like wax, wax/resin, and resin ribbons, how do you know which one is best for your business? Let’s break it down in simple terms.

Why Does the Right Thermal Ribbon Impact Label Quality?

Did you know that your thermal transfer ribbon directly affects the quality and durability of your labels? Think of it like choosing the right ink for a pen. Some inks smudge easily, while others stay crisp and waterproof. The same goes for ribbons: the wrong choice could lead to faded text or damaged barcodes, while the right thermal transfer ribbon means your labels stay clear, reliable, and professional-looking.

Wax Thermal Ribbons

Wax ribbons are the most common and affordable option. They work great for everyday labeling where the environment isn’t too harsh.

Best for:

- Shipping labels

- Retail product tags

- Warehouse labeling

- Barcode labels

Pros:

- Cost-effective

- Works well on standard paper thermal transfer labels

- Good print clarity

Cons:

- Not resistant to moisture, chemicals, or heavy handling

If your business mostly needs paper labels for short-term use or indoor use, wax ribbons can be a perfect fit. This is where people often compare wax vs resin ribbon, because resin is built for tougher conditions, while wax is great for general needs.

Wax/Resin Thermal Ribbons

Wax/resin ribbons are a mix of both materials, giving you the balance of affordability and durability. They offer sharper printing and can handle moderate environmental stress.

Best for:

- Food packaging

- Outdoor labels

- Healthcare products

Pros:

- More durable than wax

- Works on coated paper and some synthetics like polypropylene, Valeron

- Smudge and scratch-resistant

Cons:

- Pricier than wax

- Not as tough as pure resin ribbons

If you need a middle ground, wax resin ribbon uses include applications where labels need to withstand light chemicals or some outdoor exposure, but don’t require extreme durability.

Resin Thermal Ribbons

Resin ribbons are the toughest of all. They’re made to withstand harsh environments, chemicals, heat, and moisture.

Best for:

- Pharmaceutical labels

- Electronics

- Outdoor industrial use

- Waterproof or chemical-resistant labeling

- For use with polyester and vinyl labels

Pros:

- Highly durable

- Scratch, smudge, and chemical-resistant

- Long-lasting

Cons:

- More expensive than wax or wax/resin

- Requires compatible synthetic label materials

If your business demands labels that last in challenging environments, resin ribbons are the ultimate choice.

How to Decide Which Ribbon You Need

Choosing between wax, wax/resin, and resin ribbons depends on your application:

- For short-term, cost-effective labeling → Wax ribbons

- For the balance of cost and durability → Wax/Resin ribbons

- For extreme durability and specialized use → Resin ribbons

It also helps to think about your label material. Paper works best with wax, while synthetic labels often require wax/resin or resin ribbons.

Matching Ribbons with Printers and Labels

Your printer model and label material play just as big a role as the type of ribbon you choose. For example, if you’re working with a thermal transfer ribbon Zebra printer, you’ll want to double-check that the ribbon is compatible with your exact Zebra model for consistent results and long-lasting prints.

On the other hand, if your business relies on waterproof thermal printer labels, a resin ribbon is usually the better fit. Resin is designed to withstand tough environments like moisture, chemicals, and outdoor exposure, making it the go-to option for labels that need to survive in challenging conditions.

When it comes to high-volume labeling tasks, industrial thermal label printers often provide greater flexibility. They are capable of handling both wax and resin ribbons, which means you can switch between options depending on whether you need affordability for shipping labels or durability for compliance and product packaging.

For companies that already use Zebra thermal label printers, it’s smart to check the manufacturer’s guidelines on ribbon compatibility. Pairing the right ribbon with your labels not only improves print quality but also extends the life of your equipment by reducing wear and tear on the printhead.

Conclusion

Now that you understand the basics of wax, wax/resin, and resin ribbons, you can see how each type serves a specific purpose. From everyday shipping labels to chemical-resistant industrial labels, the right choice ensures your printing is clear, professional, and long-lasting.

If you want reliable supplies that keep your operations smooth, DuraFast Label Company offers a wide range of ribbon options tailored to different printers and applications. Don’t wait until faded or damaged labels slow you down. Explore the right thermal transfer ribbon today and keep your business running efficiently.

FAQs

- What are the main types of thermal ribbons?

The three main types are wax, wax/resin, and resin. Each is designed for different levels of durability and environments.

- What is the difference between wax and resin ribbons?

Wax ribbons are affordable and best for paper labels and have no resin ink in them, while resin ribbons (contain 100% resin ink) are highly durable and suitable for synthetic labels like polyester and vinyl exposed to chemicals, heat or harsh environments.

- When should I use a wax/resin ribbon?

Wax/resin ribbons are ideal when you need a balance of cost and durability, such as for food packaging or healthcare labeling.

- Do I need special labels for resin ribbons?

Yes, resin ribbons work best with synthetic label materials like polyester, vinyl or polypropylene, not standard paper labels.

- Can I use wax ribbons for outdoor labels?

No, wax ribbons are not weather-resistant. Resin ribbons with polyester labels are recommended for outdoor or long-term use.

- Are thermal ribbons universal for all printers?

Not always. Some printers, like Zebra thermal label printers, require specific ribbon sizes and formulations for best results.

- What happens if I use the wrong ribbon type?

Using the wrong ribbon can lead to poor print quality, smudging, fading, or wasted labels. Always match the ribbon to your label material and application.

- How long do printed labels last with thermal transfer ribbons?

It depends on the ribbon type. Wax may last weeks to months, wax/resin lasts longer, and resin can withstand years in harsh environments.