How to Label Circuit Breaker for Best Safety and Accuracy?

11th Feb 2026

Key Highlights

-

Proper labelling prevents accidental shutoffs of critical equipment and reduces the risk of electrical shock during maintenance.

-

Following NEC Article 408.4(A) helps ensure circuit breaker identification labels meet required safety and compliance standards.

-

Clear circuit breaker number labels allow faster identification of faulted circuits, helping reduce downtime during troubleshooting.

-

Printed labels improve legibility and give the electrical panel a cleaner, more professional appearance than handwritten markings.

-

Durable materials such as polyester tapes and ID plates resist fading, peeling, and wear better than standard paper labels.

-

Using tools like a circuit breaker finder and multimeter improves accuracy before applying permanent labels.

-

Periodic audits of the circuit breaker box label directory help keep information current and reliable.

An unlabelled or poorly labelled circuit breaker panel can cause confusion, wasted time, and safety risks, especially during power outages, repairs, or electrical emergencies. When circuits are not clearly identified, even simple tasks like turning off power to a specific room become frustrating and uncertain.

Many homes have panels with outdated, vague, or handwritten labels that no longer reflect actual circuit usage. Renovations, added appliances, and electrical upgrades often change circuits, leaving directories inaccurate and unreliable. Without proper labelling, troubleshooting becomes slower, and mistakes are more likely.

This blog explains how to label your circuit breaker correctly, avoid common labelling mistakes, and maintain clear, accurate circuit breaker identification labels so your electrical panel remains safe, organized, and easy to use long-term.

Why Is Correct Circuit Breaker Labelling Essential?

Correct circuit breaker labels play a critical role in electrical safety and efficiency. When urgency arises, clear labelling allows fast identification of the correct breaker, reducing risk during repairs, upgrades, or emergencies. Accurate markings help electricians and residents disconnect power to specific areas without causing unintended outages to essential systems. Clear labels also support compliance with the National Electrical Code, which requires legible and precise identification to protect occupants and technicians.

Circuit breaker labelling refers to assigning clear identifiers to each breaker and the main panel index. These labels show which outlets, lights, or equipment are connected to each circuit. Proper labelling creates a direct, accurate match between breakers and their endpoints, avoiding confusion during inspections, maintenance, or emergency situations.

What Tools Help You Identify Circuit Breakers Accurately?

Circuit breaker labeling is essential for safe electrical work, routine maintenance, and emergency shutoffs. Clear identification reduces guesswork, saves time, and helps prevent accidental power loss or safety hazards during panel access.

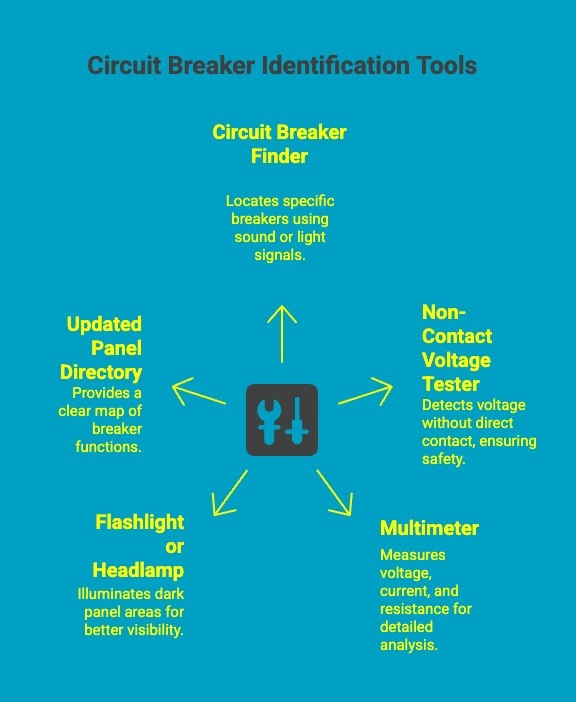

Tools That Improve Accuracy and Safety:

-

Circuit Breaker Finder: Uses a transmitter and receiver to trace which breaker controls a specific outlet or fixture quickly and reliably.

-

Non-Contact Voltage Tester: Confirms whether a wire or outlet is live without direct contact, improving safety during testing.

-

Multimeter: Measures voltage, continuity, and current to verify circuit status and confirm breaker connections.

-

Flashlight or Headlamp: Provides clear visibility inside panels, especially in low light or during power outages.

-

Updated Panel Directory: Keeps breaker descriptions current, ensuring each circuit matches its actual load.

Together, these tools support accurate circuit breaker labeling, helping technicians work confidently while maintaining safety, compliance, and long-term panel clarity.

What Types of Labels Can You Use for Circuit Breakers?

Clear, durable labels are the final step in effective circuit breaker identification. After mapping each circuit, selecting the right label type ensures long-term readability and organization. With several practical options available, choosing wisely supports safety, compliance, and easier future maintenance.

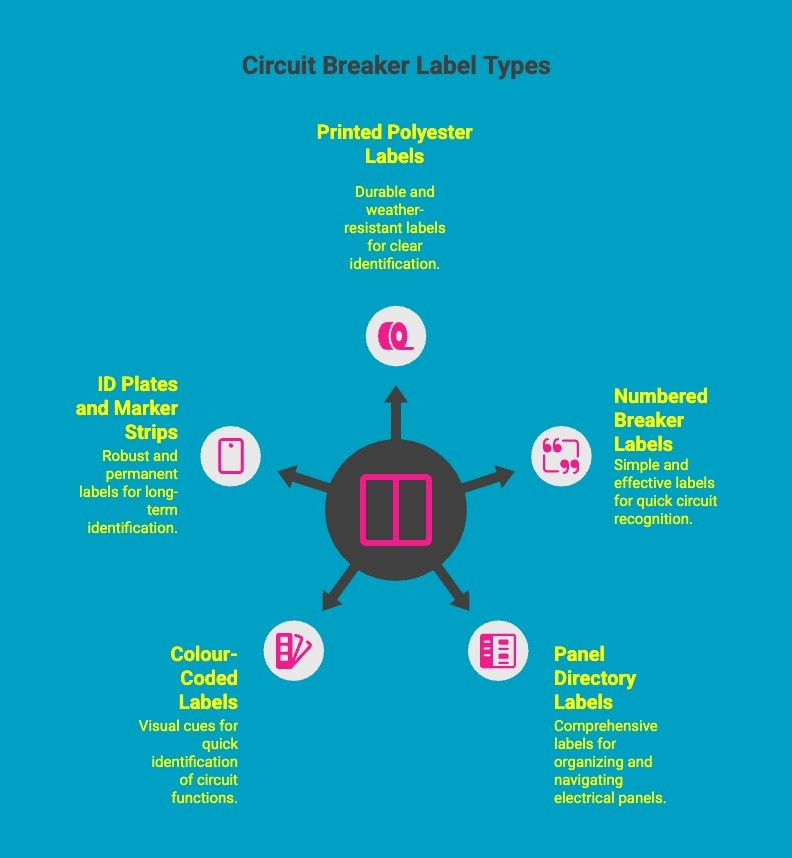

1) Printed Polyester Labels

Printed polyester labels offer a professional, long-lasting solution for circuit breaker panels. Created with a portable label maker, they produce clear, consistent text with strong adhesive backing. Electricians recommend them for eliminating handwriting errors. These labels resist moisture and fading, apply easily, and keep panels organized, readable, and compliant during maintenance or emergency shutoffs and routine electrical inspections safely.

2) Numbered Breaker Labels

A numbered breaker label system offers a clean, structured way to organize electrical panels. Each breaker receives a numbered sticker, while a separate directory explains each circuit in detail. This approach works well in tight panels, supports easy updates, and keeps breaker rows uncluttered while maintaining clear, accessible circuit information for maintenance and safety.

3) Panel Directory Labels

Panel directory labels provide a clear, central reference for all circuits in a breaker panel. Typically placed inside the panel door, the directory lists numbered breakers with detailed descriptions. This system supports thorough documentation, easier troubleshooting, and future upgrades. Custom spreadsheets or printable templates allow precise, easy-to-update circuit records.

4) Colour-Coded Labels

Colour-coded labels add a quick visual layer of organization to an electrical panel. Different colours represent different circuit types, making identification faster at a glance. This method works best alongside numbered labels or a panel directory. Consistent colour use, a clear legend on the panel door, and written circuit details ensure accuracy, clarity, and long-term usability during maintenance or emergencies.

5) ID Plates and Marker Strips

ID plates and marker strips provide a highly durable, long-term labelling solution. Common in commercial settings, engraved plastic or metal ID plates resist moisture, fading, and wear. Marker strips fit directly into panel channels for a clean, integrated appearance. Although installation takes more effort, these options deliver permanent, professional clarity that remains legible for years.

Meeting circuit breaker labeling requirements calls for durable, long-term solutions rather than temporary markings. These methods suit anyone seeking a true “set it and forget it” labeling system. They keep circuit information clear and legible for years, even in demanding electrical panel conditions.

What Electrical Codes Govern Circuit Breaker Labelling?

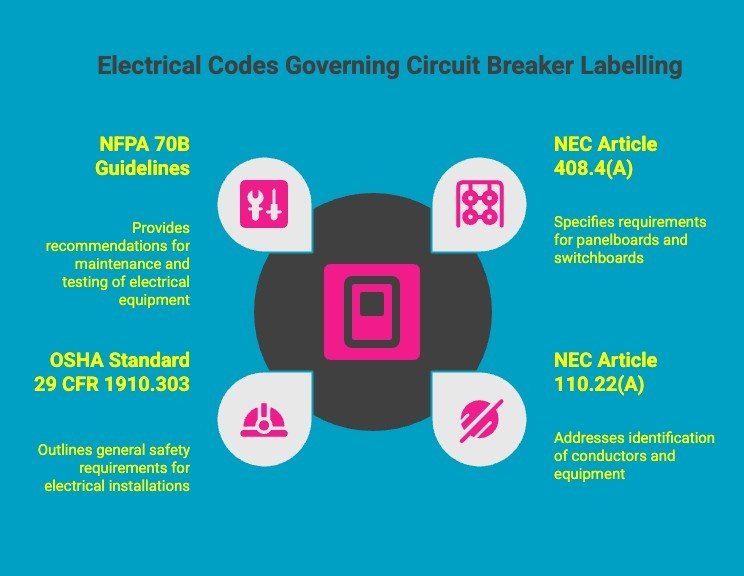

With labelling methods covered, compliance matters. The National Electrical Code sets rules electricians follow. Compliance ensures circuit identification for safety and efficiency. Next, requirements from the Occupational Safety and Health Administration and National Fire Protection Association for commercial panel applications.

Following these codes helps ensure that anyone working on your panel can quickly and accurately identify each circuit's purpose:

1) NEC Article 408.4(A)

The National Electrical Code sets clear rules for panel labelling, with Article 408.4(A) requiring every circuit to be legibly identified by its specific purpose. Vague terms are not allowed. Clear identification on the panel or directory eliminates confusion, supports safe shutoffs, and ensures compliance for homeowners, electricians, and inspectors.

2) NEC Article 110.22(A)

Another key requirement from the National Electrical Code is Article 110.22(A), which covers disconnecting means. Circuit breakers must be clearly and durably marked to show their exact purpose. This prevents accidental shutoffs or unsafe assumptions during work, ensuring anyone accessing the panel can identify circuits accurately and safely at all times.

3) OSHA Standard 29 CFR 1910.303

While the NEC addresses installation, the Occupational Safety and Health Administration focuses on safety. OSHA Standard 29 CFR 1910.303 requires electrical equipment to be clearly and specifically identified. Labels must avoid ambiguity, such as vague terms like “Lights.” Clear descriptions reduce confusion and help prevent accidents during electrical work in homes and workplaces.

4) NFPA 70B Guidelines

The National Fire Protection Association publishes NFPA 70B, which focuses on ongoing electrical maintenance. It recommends regular inspection of panel labels to ensure accuracy and legibility. Labels must be updated after any electrical changes. Maintaining clear, correct labelling reduces long-term risk and supports a safe, well-organized electrical system over time.

Using labels for circuit breaker box applications that follow electrical codes keeps circuit identification clear, accurate, and dependable. Proper compliance improves safety, simplifies maintenance, and reduces risk during emergencies. A correctly labelled panel becomes a reliable reference for anyone working on the electrical system.

Are There Label Kits or Templates for Circuit Breaker Panels?

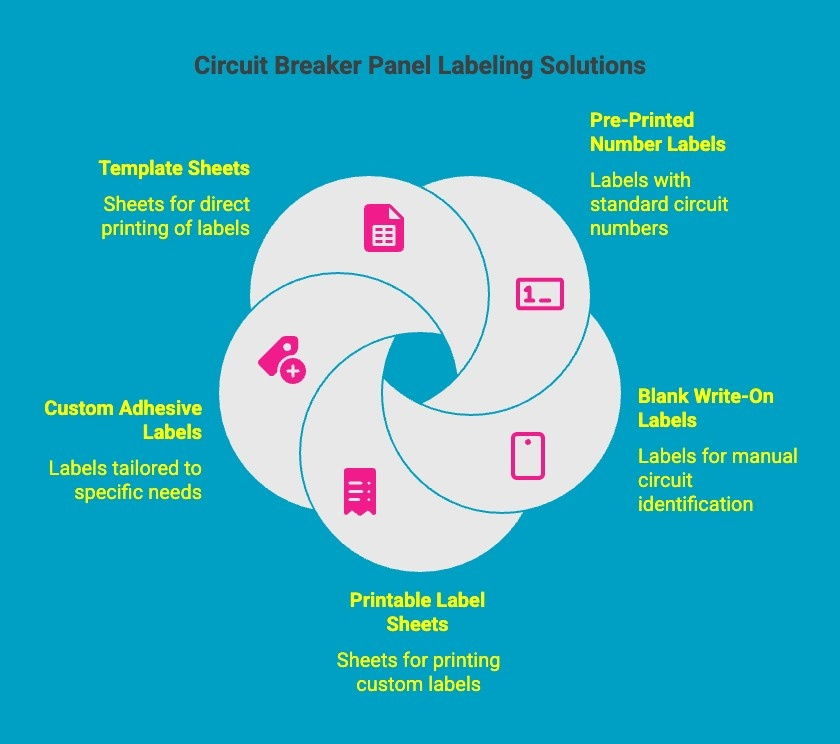

Yes, many options make panel labelling easier without starting from scratch. Pre-printed label kits and printable templates offer quick, organized results. Additionally, free downloadable directories can be customized and printed on standard or adhesive paper for a clean, professional finish.

Here are several convenient options that simplify panel labelling and help you achieve a clean, organized result without specialized tools:

1) Pre-Printed Number Labels

Pre-printed number labels are a simple way to organize a breaker panel. Adhesive-backed numbers are placed beside each breaker in sequence. A matching directory inside the panel door explains each number, keeping the panel tidy while detailed descriptions remain clearly listed and easy to update.

2) Blank Write-On Labels

Blank write-on labels are an accessible option for quick panel organization. These adhesive labels allow handwritten circuit descriptions using a fine-tip permanent marker. While less polished, they greatly improve clarity, help identify circuits during outages or maintenance, and ensure essential information is visible directly at the panel.

3) Printable Label Sheets

Printable label sheets balance handwritten labels and professional tools. Adhesive-backed sheets run through a home printer let you use typed text and organized layouts. You can print a full directory for the panel door or cut individual labels, achieving a clean, readable result without specialized equipment.

4) Custom Adhesive Labels

Custom adhesive labels made with a portable label maker offer the most professional finish. Each circuit description is printed clearly and applied directly to the breaker. Durable materials resist fading and peeling, providing long-term clarity, improved safety, and a neat, consistent appearance throughout the panel.

5) Template Sheets for Direct Printing

Template sheets for direct printing provide a structured way to label panels. Downloadable files include formatted columns for breaker numbers and descriptions. After filling in details digitally, you print on adhesive paper and apply it inside the door, creating a professional directory that is easy to update later.

Choosing the right labels for a circuit breaker box setup depends on your tools, time, and preferences. However, any of these labelling options will improve safety, clarity, and organization, making your electrical panel easier to understand and manage now and in the future.

What Common Mistakes Should You Avoid When Labelling Circuit Breakers?

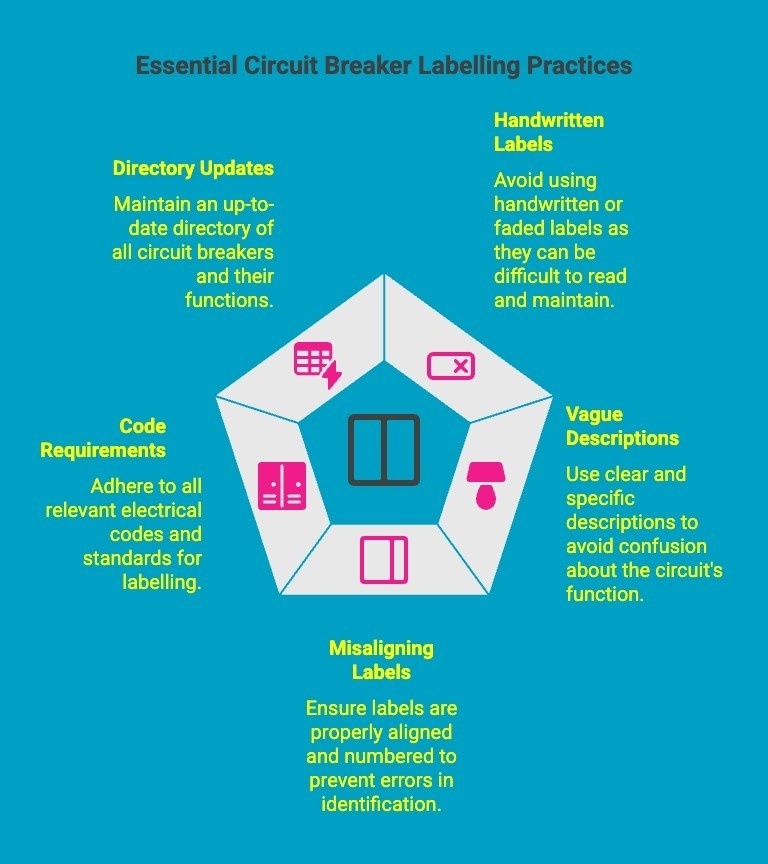

Accurate circuit breaker labelling is essential for safety, compliance, and ease of maintenance. Understanding circuit breaker labelling requirements helps prevent mistakes that reduce clarity or cause confusion when the panel needs to be referenced.

Common mistakes to avoid include:

-

Using Handwritten or Faded Labels: Handwritten text and low-quality ink can fade or smudge over time, making circuit identification unreliable during urgent situations.

-

Using Vague or Generic Descriptions: Labels such as “Lights” or “Outlets” lack clarity. Specific locations or functions make it easier to identify the correct circuit quickly and safely.

-

Misnumbering or Misaligning Labels: Improper use of circuit breaker number labels or placing labels beside the wrong breakers can lead to confusion and accidental shutdowns.

-

Ignoring Code Requirements: Electrical standards require clear, accurate identification. Overlooking circuit breaker labelling requirements can result in non-compliance and potential safety issues.

-

Failing to Update the Directory After Changes: Panel directories must be revised whenever circuits are added, removed, or modified to keep information accurate and dependable.

Careful, specific labelling ensures your electrical panel remains organized, readable, and reliable whenever it needs to be referenced.

How Should You Maintain a Properly Labelled Circuit Breaker Panel?

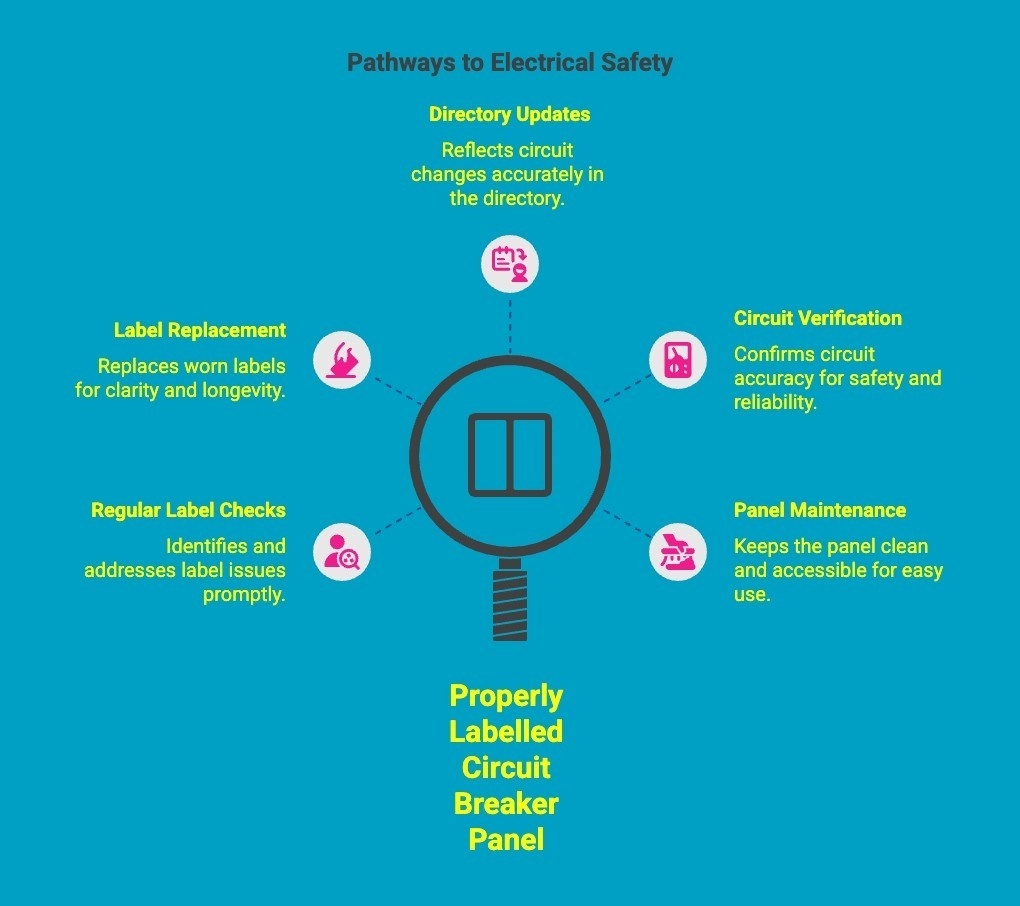

Maintaining your labels is just as important as creating them. A well-maintained circuit breaker box label system ensures information stays accurate, readable, and useful as your electrical needs change over time.

Here are the key practices to keep your circuit breaker identification labels. reliable:

-

Check Labels Regularly: Inspect labels periodically to confirm they remain legible, securely attached, and correctly positioned next to the proper breakers.

-

Replace Worn or Faded Labels: Any label showing fading, peeling, or damage should be replaced promptly to prevent confusion during maintenance or emergencies.

-

Update the Directory After Changes: Whenever circuits are added, removed, or modified, update the panel directory immediately so it continues to reflect actual usage.

-

Verify Circuit Accuracy Periodically: Test breakers occasionally to ensure each label still matches the circuit it controls, especially after renovations or electrical work.

-

Keep the Panel Clean and Accessible: Avoid clutter around the panel and keep the area clean so labels and directories remain easy to read and access when needed.

Keeping labels accurate, readable, and up-to-date ensures your circuit breaker panel remains safe, organized, and easy to use during maintenance, troubleshooting, or emergency situations.

How Do You Label a Circuit Breaker? (Step-by-Step)

Labelling a circuit breaker correctly improves safety, reduces confusion, and makes future maintenance much easier. A clear, structured approach ensures every circuit is accurately identified and easy to reference when needed.

Here are the key steps on how to label your circuit breaker properly so your electrical panel remains organized, accurate, and safe to use over time:

1) Gather Your Tools And Update The Panel Map

Start by gathering labels, a permanent marker or label maker, and a flashlight. Review or create a panel map listing all circuits. Having this reference ready helps prevent mistakes, keeps the process organized, and ensures each breaker is labelled accurately from the beginning.

2) Verify Safety and Identify Each Circuit

Before testing circuits, make sure the area is dry and well lit. Switch breakers one at a time and confirm which outlets or fixtures lose power. This step verifies accuracy and prevents mislabeling that could cause confusion during future repairs or emergencies.

3) Label Each Breaker Clearly With Required Details

Write clear, specific descriptions for each breaker, including room names and functions. Avoid generic terms. Accurate details make it easy to isolate circuits quickly, especially when troubleshooting electrical issues or responding to an unexpected power outage.

4) Use Durable Labels and Apply Them in Key Locations

Choose durable, adhesive labels that resist fading and peeling. Place them neatly beside each breaker and ensure they do not cover manufacturer information. Durable labels keep your panel readable and reliable over time, even in warm or humid conditions.

5) Test the Labels and Document the Updated Panel

After labelling, test breakers again to confirm each label matches its circuit. Update the panel directory and keep a digital or paper copy for records. This documentation helps maintain accuracy as electrical changes occur in the future.

Taking the time to label your circuit breaker panel properly creates a safer, more organized electrical system that remains easy to understand and maintain long-term.

Searching for a Reliable Circuit Breaker Labelling Printer? Try the MAX LETATWIN LM-550A3BH.

If you want professional, long-lasting results for electrical panel labelling, a dedicated printer is the right choice. The MAX LETATWIN LM-550A3BH allows you to create clear, custom labels that will not fade, peel, or smudge over time, meeting professional and safety standards.

Investing in a purpose-built printer also gives you flexibility beyond a single project. You can label panels, cables, equipment, and assets while keeping digital records for easy updates. For guaranteed authenticity, expert guidance, and ongoing support, purchase the LETATWIN LM-550A3BH from DuraFast Label Company.

Contact DuraFast Label Company to get expert help choosing the right circuit breaker labelling printer and supplies.

Conclusion

Properly labelling a circuit breaker panel is a simple yet important step in maintaining a safe and organized electrical system. Clear, accurate labels reduce guesswork during maintenance, speed up troubleshooting, and help prevent costly or dangerous mistakes during emergencies. A well-maintained panel also supports code compliance and makes future upgrades or repairs far easier to manage.

By using durable labels, keeping the directory updated, and periodically verifying accuracy, homeowners and professionals can ensure the panel remains reliable over time. Investing a little effort upfront delivers long-term clarity, improved safety, and confidence whenever electrical work is required.

Frequently Asked Questions

What Are the Steps to Properly Label a Circuit Breaker Panel in My Home?

First, test each breaker by switching it off and noting what loses power. Record details, then create durable, clear labels with a label maker or printed directory. Apply labels neatly, ensuring accuracy, safety, and clarity.

What Tools or Materials Do I Need to Label Circuit Breakers?

You'll need tools to identify circuits, such as a circuit detector or a partner. Gather adhesive labels, a label maker, a pen, a notepad, and a flashlight to clearly see, write, and apply accurate circuit information safely inside.

How Can I Test Which Circuit Breaker Controls a Specific Outlet or Appliance?

Plug a tester or small appliance into the outlet. Switch breakers off one at a time until power stops. That breaker controls the outlet. For major appliances, have a partner watch while you test safely.

Are There Label Kits or Stickers Available Specifically for Circuit Breaker Panels?

Yes, many home improvement stores sell breaker panel label kits. They include pre-printed room, appliance, or number stickers used with a directory, helping organize circuits quickly, neatly, and consistently without custom printing or special tools.

What Is the Safest Way to Label a Circuit Breaker Without Turning Off the Power?

The safest method is using a circuit detector. Plug a transmitter into an outlet, then scan breakers with a receiver. It identifies circuits without flipping switches, reducing contact with live components and improving safety during.

What Are the Regulations for Electrical Panel Labels?

The National Electrical Code requires breaker panel labels to be clear, specific, and permanent. Each circuit must state its exact purpose. Vague descriptions are not allowed, ensuring safety, compliance, and clarity for anyone servicing panels.

How Often Should I Check and Update the Labels on My Circuit Breaker Panel?

You should review breaker panel labels annually for accuracy and legibility. Update them immediately after renovations, new appliances, or changes. Following proper labeling and electrical panel labeling best practices keeps circuit information current and reliable during maintenance or emergencies.