How to Mark Electrical Wires: Top Techniques and Tips

21st Jan 2026

Key Highlights

• Properly marking electrical wires prevents confusion, improves safety, and saves time during installation or maintenance.

• Common labeling methods include wrap-around markers, sleeve markers, and self-laminating adhesive labels.

• Use durable materials like vinyl, polyester, or heat-shrink tubing for long-lasting, professional wire identification.

• Label both ends of every wire, keep cable markings consistent, and document your labeling system for easy reference.

• Choose cable labels that match your project environment such as adhesive for home use or heat-shrink for industrial and high-heat areas.

• Avoid common mistakes like poor placement, inconsistent codes, or using low-quality materials that fade or peel.

• For reliable wire labeling tools and materials, trust DuraFast Label for durable products, fast delivery, and expert support.

Ever opened a junction box only to find a confusing tangle of identical wires that all look the same? It’s one of the most common and frustrating issues in any wiring project.

When wires aren’t properly labeled, even a simple fix can turn into hours of trial and error, unnecessary rework, or safety risks. That’s why understanding how to mark electrical wires correctly is essential for both professionals and DIY enthusiasts.

From identifying circuits to maintaining motor connections, clear labeling makes troubleshooting and system modifications faster and safer.

In this guide, you’ll discover effective wire marking methods, explore reliable labeling materials, and see how a professional wire printer can make the process effortless. These practical tips will help you keep your wiring organized, durable, and easy to maintain.

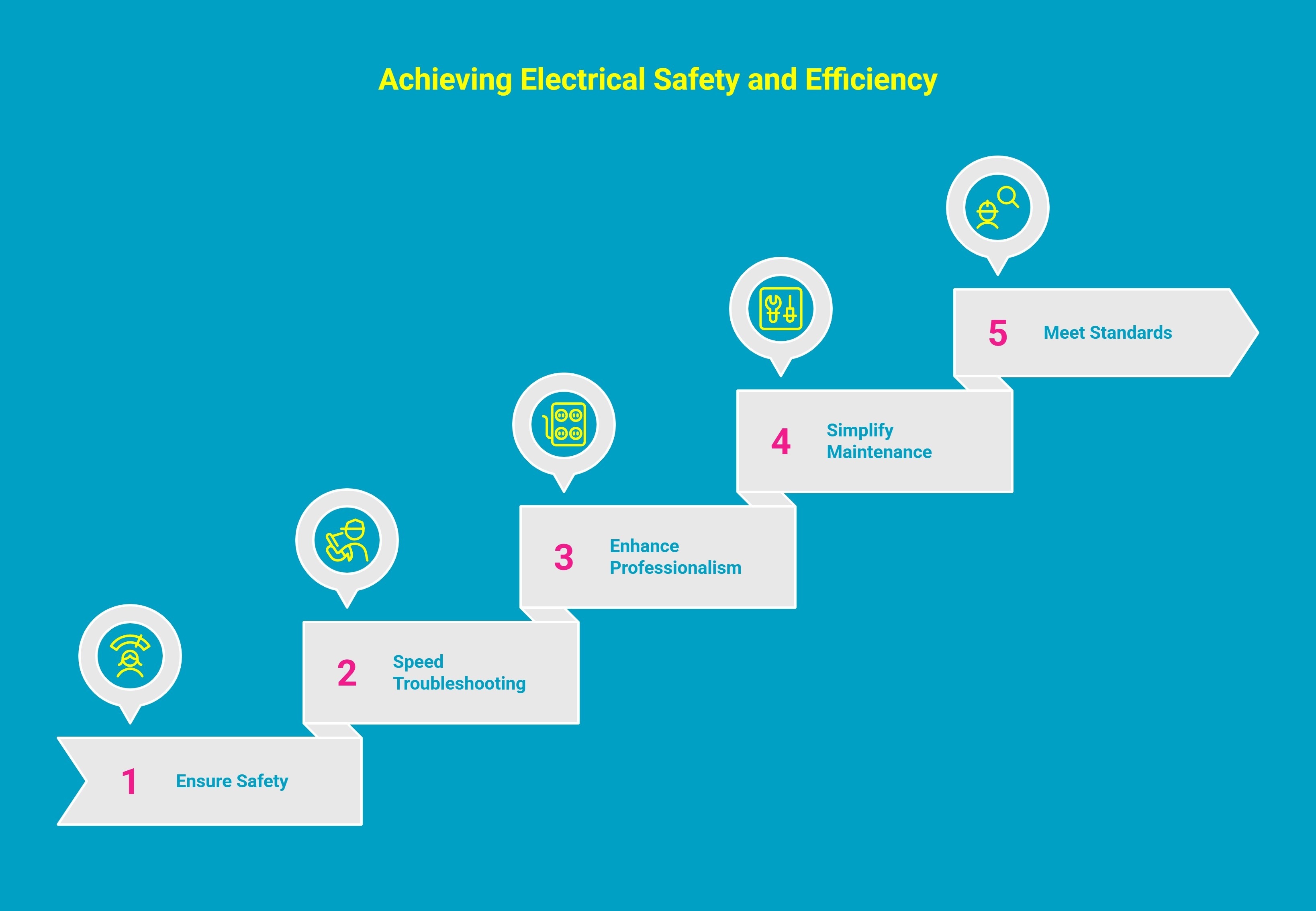

Why Should You Always Label Your Electrical Wires?

When it comes to electrical work, even the most skilled technician can face problems if the wiring isn’t clearly labeled. A well-marked system is not just about neatness; it is about safety, efficiency, and long-term reliability. Taking a few extra minutes to label your wires properly can prevent costly mistakes and make every future task easier.

Why Electrical Wire Labeling Matters:

-

Improves Safety: Clear labeling helps identify live, ground, and data lines, reducing the risk of electrical shocks, shorts, and accidental disconnections.

-

Simplifies Troubleshooting: Marked wires make it faster to trace circuits, locate faults, and perform repairs without guesswork.

-

Shows Professionalism: Clean, organized labels demonstrate craftsmanship and attention to detail, whether in home panels or industrial systems.

-

Eases Future Maintenance: Consistent markings ensure anyone servicing the system later can quickly identify connections and work safely.

-

Supports Compliance: Proper identification helps meet NEC and inspection requirements, avoiding potential safety violations or project delays.

Clear wire labeling keeps every connection easy to identify, reduces errors, and ensures your electrical systems remain safe and efficient for years to come.

What Are the Most Common Methods for Marking Electrical Wires?

When it comes to cable labeling, choosing the right method makes all the difference. The type of insulation, number of wires, and whether the cable is already connected all affect how well a label adheres and stays readable over time. Using the right approach ensures your labels remain clear, durable, and compliant for any application.

For wires that are already connected, wrap-around markers are your best option. If you are working with wires before they are terminated, you have more choices. Here are the primary methods:

1. Wrap-Around Markers

Wrap-around markers are adhesive electrical wiring labels designed to wrap around cables or wires after they’ve been terminated. They’re used when labels need to be applied without disconnecting any connections, making them perfect for upgrades or retrofits.

The self-laminating versions include a clear overlay that protects printed text from smudging, heat, and moisture for long-lasting clarity.

2. Sleeve Markers

Wrap-around markers are adhesive electrical wiring labels designed to wrap around cables or wires after they’ve been terminated. They’re used when labels need to be applied without disconnecting any connections, making them perfect for upgrades or retrofits.

The self-laminating versions include a clear overlay that protects printed text from smudging, heat, and moisture for long-lasting clarity.

Both methods meet ANSI and UL labeling recommendations, ensuring your wire identification is reliable, safe, and inspection-ready for any environment.

Tools of the Trade: How to Label Electrical Wires Like a Pro?

Choosing the best product for labeling can completely change how smoothly your electrical projects run. The right tools make your work safer, faster, and more organized.

Whether you’re labeling a few wires in your garage or managing miles of cabling in an industrial plant, having dependable wire-marking products ensures accuracy and professionalism every time.

1. Pre-Printed Electrical Wire Markers

Pre-printed electrical wire markers are a go-to choice for electricians who want quick, professional results. These ready-to-use labels come with numbers, letters, or symbols already printed, so you can easily match each wire to its function.

Made from durable materials like vinyl or polyester, they resist wear, heat, and moisture. They’re perfect for busy environments like control panels or data centers where clarity and consistency matter.

2. Write-On Wire Labels

When you need flexibility, write-on labels are your best friend. These electrical wire marking labels allow you to jot down any custom note directly onto the label with a permanent marker.

They’re great for one-off projects or situations where each wire serves a unique purpose. Once wrapped around the wire, they stay secure and easy to read, offering a simple and affordable solution for small-scale jobs.

3. Heat-Shrink Tubing Labels

If you’re working in demanding environments, heat-shrink labels are hard to beat. Made from special tubing that shrinks tightly when heated, these labels won’t peel, fade, or come loose.

They’re resistant to oil, water, and chemicals, making them ideal for industrial systems and electric motor wire marking & connections. Once applied, they give a clean, professional look that lasts for years.

4. Adhesive Electrical Wire Marking Labels

Adhesive labels are among the most versatile and widely used options. They come in rolls or sheets and stick directly onto wires or cables. Most are made from heavy-duty vinyl or polyester to handle heat and humidity.

These labels are ideal for everyday use, providing a balance between durability, readability, and convenience across both residential and commercial setups.

5. Electrical Wire Marking Machines

If you work with a large volume of wires, an electrical wire marking machine can save you hours of manual effort. These printers let you create custom labels with text, barcodes, or serial numbers, ensuring perfect precision every time.

Many models connect to computers or mobile apps so you can design and print labels in batches. It’s the ultimate tool for professionals who value accuracy and speed.

6. Color-Coded Sleeves and Rings

Sometimes, the simplest solution is the most effective. Color-coded sleeves and rings make it easy to identify circuits or functions at a glance.

Each color can represent a specific phase, polarity, or connection type. They’re durable, reusable, and work great in combination with traditional electrical wire markings for quick, visual organization.

Each of these tools helps you stay organized, efficient, and safe. Choosing the right mix of products ensures your labeling system fits your workflow, whether you’re managing a few connections or wiring an entire facility.

How Does an Electrical Wire Printer Simplify the Labeling Process?

Labeling electrical wires manually can be time-consuming and prone to inconsistencies. Handwritten tags may smudge, fade, or vary in size, making them difficult to read over time. An electrical wire printer eliminates these issues by producing clear, durable, and uniform labels designed specifically for professional environments.

Here are some of the key ways a wire printer simplifies and improves the labeling process:

1. Prints Clear Labels That Stay Readable

A wire printer delivers sharp, high-contrast text that remains easy to read for years. Whether you’re printing numbers, barcodes, or circuit identifiers, every label looks professional and consistent.

2. Cuts Labeling Time Dramatically

Instead of writing labels one by one, you can print entire sets in seconds. Many printers let you import data directly from spreadsheets or design files, reducing repetitive work and avoiding costly errors.

3. Handles Any Labeling Job with Ease

Modern wire printers work with a wide range of materials, including heat-shrink tubing, self-laminating wrap-around labels, and adhesive tapes. That means one device can handle everything from panel labels to cable bundles.

4. Elevates the Look of Your Work

Printed labels give wiring a clean, uniform appearance that reflects attention to detail. Beyond aesthetics, this level of consistency helps meet NEC, ANSI, and UL labeling standards.

5. Keeps Labels Durable and Reliable

High-quality printers use long-lasting inks and materials that withstand heat, oil, and vibration. Your labels stay intact and legible even in tough industrial environments.

Using a wire printer not only streamlines your workflow but also ensures every label meets professional standards for safety, clarity, and durability.

What’s the Best Way to Label Electrical Wires for Every Type of Project?

A well-labeled wiring system is the difference between smooth maintenance and costly guesswork. Whether you’re tackling a quick home project or managing complex industrial wiring, your labeling method determines how safely and efficiently that system runs.

Let’s look at how to label electrical wires the right way for each application.

1. Smart Labeling for Home and Residential Projects

For residential wiring, clarity and simplicity are key. Write-on or pre-printed electrical wire markers make it easy to identify circuits during upgrades or repairs. They’re quick to apply, affordable, and perfect for small projects like lighting, appliances, or outlets.

Tips for home labeling:

-

Use numbered or color-coded markers to match your breaker connections

-

Label both ends of every wire for easy tracing during maintenance

-

Cover labels with clear tape or sleeves in areas exposed to dust or moisture

2. Durable Labeling for Commercial and Industrial Systems

In factories and large facilities, wiring systems are complex and subject to harsh environments. Here, durability and consistency are essential. Adhesive electrical wire marking labels and heat-shrink tubing are ideal because they resist oil, chemicals, and heat. Many professionals also use electrical wire printers to produce uniform, professional-grade labels.

Tips for industrial labeling:

-

Choose laminated or heat-shrink labels for long-lasting results

-

Include numbers, voltage ratings, and connection details on each label

-

Use color-coded systems to quickly identify circuits or phases

3. Precision Labeling for Motors and Machinery

When labeling electric motor wire marking & connections, precision matters. A single wrong label can lead to performance issues or damage. Heat-shrink labels offer a snug, durable fit that resists vibration and heat, keeping your markings clear and secure.

Tips for motor labeling:

-

Apply abrasion-resistant labels near terminal ends for clarity

-

Follow manufacturer-recommended color codes for consistency

-

Use an electrical wire printer for neat, legible, and long-lasting results

4. Organized Labeling for Data and Network Cabling

Data and communication wiring needs labels that are compact, flexible, and easy to read. Adhesive or flag-style labels are perfect for organizing Ethernet, audio, or control cables in tight spaces.

Tips for data labeling:

-

Label both ends of each cable ties to simplify troubleshooting

-

Use small adhesive markers that don’t obstruct connectors

-

Group cables neatly and maintain a clear labeling map

The right labeling approach saves hours of troubleshooting and ensures long-term safety. Investing in durable, high-quality labels means fewer mistakes, faster maintenance, and a cleaner, more efficient wiring system overall.

Top Wire Labeling Mistakes That Cost You Time (and How to Avoid Them)

Even when your wiring job is technically perfect, poor labeling can undo all that hard work. Faded labels, inconsistent markings, or missing identifiers can turn simple maintenance into a frustrating guessing game. Worse, unclear labeling can cause costly electrical errors or safety hazards.

Below, we’ll look at the most common mistakes people make in wire marking system and how you can avoid them with smart, reliable solutions.

Problem 1. Using Low-Quality Labels That Don’t Last

Cheap paper labels or weak adhesives quickly peel, fade, or fall off under heat or moisture.

Fix: Use industrial-grade vinyl, polyester, or heat-shrink labels designed to withstand harsh environments. Heat shrink tubing works best for wires exposed to vibration or movement.

Problem 2. Mixing Labeling Styles or Systems

Combining numbers, colors, or letters randomly creates confusion and inspection issues.

Fix: Use one consistent system, such as numeric for circuits and color coded for voltage, and keep a master legend for reference.

Problem 3. Labeling Only One End of Each Wire

When only one end is labeled, tracing wires during maintenance becomes tedious.

Fix: Label both ends near terminals and junctions for quick identification and fewer mix ups.

Problem 4. Poor Legibility and Placement

Handwritten or hidden labels lose clarity over time.

Fix: Print labels using a professional wire marking machine with bold fonts and high contrast. Place them where they are clearly visible.

Problem 5. Leaving Labels Unprotected

Even quality labels degrade without protection in hot or oily environments.

Fix: Use clear heat shrink sleeves or laminates to protect labels, especially on motor connections or high vibration areas.

Problem 6: Skipping Documentation

Without a labeling log, even perfect labels can confuse future technicians.

Fix: Keep a simple digital or printed record linking each label to its circuit or connection point.

Durable materials, consistent systems, and proper protection keep your wiring clear, compliant, and easy to maintain, saving time and preventing costly errors.

Why DuraFast Label Is the Go-To Choice for Reliable Wire Marking?

Nothing is more frustrating than watching your carefully labeled wires fade, peel, or fall off after a few months. Poor-quality labels don’t just waste time; they lead to confusion, safety risks, and unnecessary rework.

For anyone who values accuracy and organization, choosing a dependable labeling brand is key, and that’s where DuraFast Label Company truly stands out.

We specialize in industrial-grade labels, printers, and supplies built for long-lasting performance. Every product is designed to deliver sharp, durable results that can handle tough environments such as electrical panels, machinery, and outdoor installations.

What makes DuraFast a trusted choice:

-

Labels that withstand heat, humidity, and abrasion without losing clarity

-

A complete range of products including printers, ink, and accessories

-

Easy-to-use labeling systems ideal for both professionals and DIY users

-

Reliable customer support and fast delivery across Canada and the US

With DuraFast, you are not just purchasing labels; you are investing in precision, organization, and peace of mind.

Ready to upgrade your labeling process? Contact Us today!

Conclusion

Great electrical work isn’t just about making the right connections; it’s about making them clear. A well-labeled system speaks volumes about your precision, professionalism, and pride in your craft.

Labeling isn’t a task to rush; it’s the detail that defines quality. Each marker you place is a statement of care, clarity, and confidence in your work.

Label with purpose, wire with pride, and let your work stand as a mark of true craftsmanship.

Frequently Asked Questions

Can I print my own electrical wire labels?

Yes, you can print wire labels using a laser or thermal transfer printer. Self-laminating polyester sheets create durable, professional markers for reliable cable labeling.

Are heat-shrink labels better than adhesive labels?

Heat-shrink labels are more durable for harsh environments, while adhesive labels are easier to apply after termination. Both work well depending on the project’s conditions.

What are electrical wire marker numbers used for?

Electrical wire marker numbers identify and organize wires within circuits or panels, helping trace connections quickly during installation, maintenance, or troubleshooting.

Do I need a special printer for wire labeling?

A dedicated electrical wire printer ensures the best results, but you can also use a laser printer with compatible label sheets for smaller or occasional tasks.

How do I label electric motor wires correctly?

Use heat-resistant, vibration-proof labels showing voltage, phase, and terminal data. Follow standard color codes and ensure clarity for safe, accurate motor wiring.

Where can I purchase reliable wire marking labels online?

You can find high-quality wire labeling products and printers at DuraFast Label, offering durable materials, fast delivery, and expert support.

Where can I purchase reliable wire marking labels online?

You can buy durable wire marking labels and printers from DuraFast Label. They offer high-quality materials, fast shipping, and expert guidance for professional labeling projects.

What do the standard colors and codes on electrical wire labels mean?

Electrical wire label colors indicate function: black for power, white for neutral, green or green-yellow for ground, red for secondary live, and blue for low-voltage or control circuits.