How To Simplify Numbering Electrical Wires With MAX Letatwin Printers?

2nd Feb 2026

Key Highlights

-

Wire numbering is critical in industrial electrical systems because it prevents confusion, reduces errors, and makes troubleshooting faster.

-

MAX Letatwin printers let professionals print clean, durable markings directly on tubes and heat-shrink sleeves.

-

They print quickly (up to 40mm/sec) with 300 dpi clarity, ideal for large batch, sequential wire numbering jobs.

-

One device works with tubes, shrink sleeves, and tapes, eliminating the need for multiple marking tools.

-

For best results, choose the right tube size, maintain your printer, and always use original MAX consumables.

-

DuraFast sells genuine MAX Letatwin printers and supplies, ensuring peak performance, reliable quality, and long-lasting markings.

In industrial electrical systems, messy, handwritten, or poorly marked wires can quickly lead to unnecessary confusion. Clear identification ensures technicians can quickly isolate issues without repeatedly tracing cables back to their source.

Thankfully, numbering wires doesn’t have to be slow, manual, or inconsistent. With MAX Letatwin printers, electricians can print clear, durable markings directly on tubes and heat-shrink sleeves, making wire identification far more accurate.

In this blog, we’ll show why wire numbering is crucial in industrial environments, how MAX Letatwin simplifies the entire process, best practices to get the cleanest results, and where to source genuine MAX printers and supplies for your projects.

Why Is Numbering Electrical Wires So Important in Industrial Settings?

Numbering electrical wires is extremely important in industrial settings. There are multiple machines, control panels, PLCs, and junction boxes running hundreds of conductors, which can add to the complexity. When the wires are not labelled, it becomes almost impossible to identify connections accurately during installation, repair, or emergency breakdowns.

Here are some key reasons why wire numbering is crucial:

-

Speeds up troubleshooting when a fault occurs. Technicians can trace circuits instantly.

-

Improves safety by reducing the chances of someone touching or disconnecting the wrong wire.

-

Prevents wiring mistakes during new installation or expansions of an existing system.

-

Supports clear documentation and aligns with electrical schematics and industrial standards.

-

Reduces downtime as machines get back to production faster.

-

Helps new technicians understand the system layout quickly, without relying on tribal knowledge.

In short, proper wire numbering is not just an organisational preference. It directly drives safer workflows, faster maintenance, and more reliable system performance across the entire plant.

How Does MAX Letatwin Simplify Numbering Electrical Wires for Professionals?

The MAX Letatwin LM-550A3BH/PC is designed specifically for electricians, electrical panel builders, and industrial maintenance teams. It helps them with fast, accurate, and durable wire identification. Instead of wasting time handwriting labels or dealing with slow, inconsistent printers, this device helps professionals print clean, high-resolution numbers and text directly onto tubes, heat-shrink sleeves, and tapes, ensuring electrical systems remain organised, easier to maintain, and compliant with industrial standards.

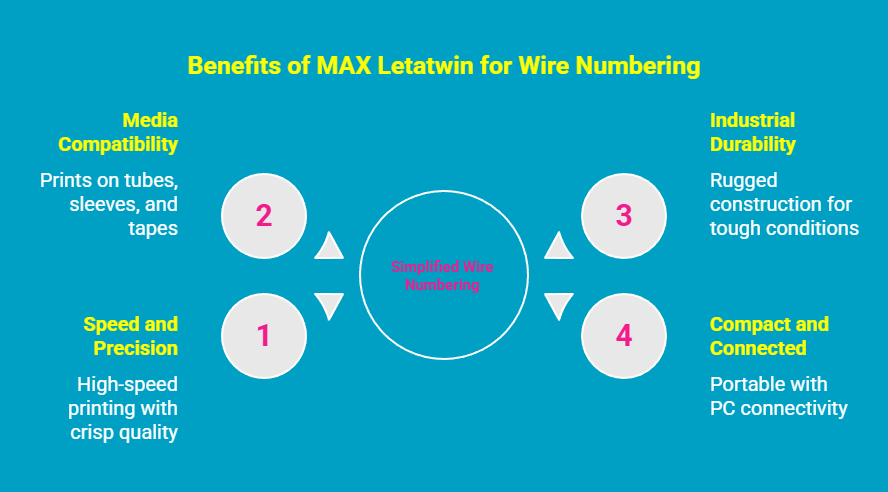

1. Speed and Precision in Every Print

The Letatwin offers high-speed thermal transfer printing (up to 40mm/sec) with crisp 300 dpi print quality, so technicians can generate large batches of wire markers quickly without compromising clarity. This is especially useful when printing long sequential runs of numbered wires for panels, harnesses, or PLC connections.

2. Compatible With Tubes and Heat-Shrink Sleeves

One of the biggest benefits of the Letatwin is that it can print directly on PVC tubes, heat-shrink sleeves, and tapes. This eliminates the need for separate machines for different media types. Whether you’re marking standard wire tubes or shrink sleeves for tighter cabinets, one device handles everything.

3. Industrial Durability That Lasts

The printer is built with rugged construction suitable for workshop and job-site environments, offering consistent print quality even in demanding conditions. It also supports low-temperature printing modes, ensuring the electric motor wire numbers remain sharp and legible. This is particularly useful when you're working in production lines, field sites, or cold industrial zones.

4. Compact, Connected, and Easy To Operate

Despite its industrial capabilities, the Letatwin remains compact and portable, making it easy to carry to on-site installations. It also connects to PC software for importing data, sequential numbering lists, or pre-prepared label files, allowing teams to speed up repetitive labelling tasks and minimise manual typing.

Together, these features make the MAX Letatwin a practical, time-saving tool that helps professionals standardise wire labels and deliver more compliant electrical installations.

How To Get the Best Results When Numbering Electrical Wires?

Getting crisp, durable, and accurate markings is not always about using the right printer or the right wire material. You also need to focus on choosing the correct sleeves and consumables that can withstand industrial conditions. A few small best practices can significantly reduce rework during installations or maintenance. Here they are:

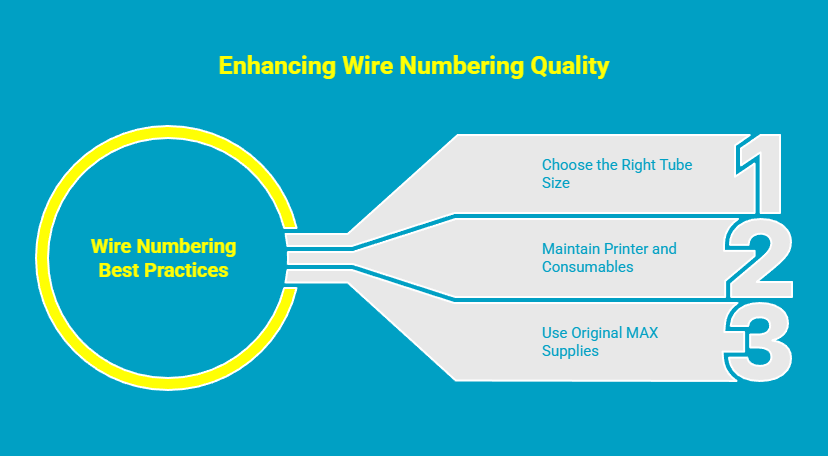

1. Choose the Right Tube Size for Each Wire

Make sure the tube or heat-shrink sleeve diameter matches the wire gauge you’re marking. A sleeve that’s too tight may tear or distort during shrinking, while a sleeve that’s too loose won’t sit firmly and may rotate, making the wire number harder to read later. Always pick a size according to the pre-shrink diameter. This ensures that the sleeve slides over the wire easily but still provides a snug fit after shrinking.

2. Keep Printer and Consumables in Optimal Condition

Clean the printer head periodically, replace ribbons before they get too worn, and store tubes and shrink sleeves away from heat or direct sunlight. Well-maintained equipment ensures consistent print density and prevents smudging. Simple care, like dust-free storage and regular inspection, keeps the print output sharp and prevents unexpected print failures.

3. Use Original MAX Letatwin Supplies

Original MAX tubes, shrink sleeves, ribbons, and tapes are engineered to work perfectly with the Letatwin’s thermal transfer system, ensuring better adhesion, sharper print contrast, and longer durability. Third-party consumables may appear cheaper, but they often compromise print clarity, cause more wastage, and may even shorten printhead life. Original supplies guarantee best-in-class results and reduce the overall total cost of ownership.

Looking for Genuine MAX Letatwin Printers for Numbering Electrical Wires? Choose DuraFast

If you’re looking for genuine MAX Letatwin printers and supplies, DuraFast is your trusted source. We don’t just stock the full range; we specialise in them. That means you get original MAX models, the correct tubes and shrink sleeves, and consumables engineered for flawless performance with these printers.

We only carry authentic MAX products because industrial labelling is not an area where “compatible” or low-grade supplies are worth the risk. With DuraFast, you get guaranteed quality, fast shipping, and personalised support from a team that actually understands electrical identification, so that you can order with confidence and keep your projects running on schedule.

Conclusion

An electrical panel wire numbering doesn’t have to be complicated. The right tools make all the difference. With MAX Letatwin printers, professionals can streamline wire identification, reduce mistakes, and maintain cleaner electrical wire numbering system with confidence. Whether you’re building a new industrial control panel or expanding existing machinery using new wire, using proper wire markers and genuine MAX consumables gives you speed, clarity, and long-lasting print quality. Invest in the right printing solution and supplies now, and you’ll save time and make ongoing maintenance dramatically easier for years to come.

Frequently Asked Questions

What are the standard methods for numbering electrical wires in a control panel?

Common methods for control panel wiring include printing on tubes or heat-shrink sleeves, printing adhesive tapes, and using engraved markers. Most professionals now prefer heat-shrink sleeves printed through machines like MAX Letatwin for clarity, accuracy, and faster installation.

Why is it important to number electrical wires during installation?

Electrical schematic wire numbering during installation ensures every connection can be traced instantly later. It reduces troubleshooting time during the hour of downtime, prevents too much reliance on electrical wire colors numbers, and prevents safety hazards during repairs.

How should numbered wires be labeled to ensure easy identification and maintenance?

Use clear numbering aligned with your schematic reference, positioned near the termination, and printed using durable sleeves or tape. Labels should remain readable after heat shrinking and should match the documentation of control circuits exactly for quick future identification.

What mistakes should I avoid when numbering electrical wires?

Avoid using generic markers, wrong tube sizes, handwritten labels, or cheap ink ribbon substitutes. Also, avoid skipping numbering on short runs and rely only on electrical wire color code numbers, because even small projects become difficult to maintain when wires aren’t consistently identified.

Where can I buy genuine MAX Letatwin printers and accessories for numbering electrical wires?

You can purchase original MAX Letatwin printers, tubes, shrink sleeves, and ribbons from MAX-certified dealers and reputable online stores like DuraFast. Always choose official supplies to ensure durability, sharp print quality, and full compatibility.