What Are OSHA Electrical Panel Labeling Requirements?

12th Feb 2026

Key Highlights

-

OSHA electrical panel labeling improves workplace electrical safety.

-

Proper labels help prevent accidents, downtime, and costly violations.

-

Requirements include identification, warnings, clearance, and durability.

-

Regular audits and consistent labeling reduce OSHA inspection risks.

-

Using compliant tools simplifies long-term compliance.

Electrical panels are often overlooked until something goes wrong. Missing labels, unclear warnings, or blocked access can turn routine maintenance into a serious safety risk, leading to confusion, delayed responses, and costly violations during inspections or emergencies.

What happens when electrical panels aren’t clearly labeled? Workers are forced to guess during maintenance or emergencies, increasing the risk of mistakes, delayed response, and accidental contact with energized equipment. OSHA electrical panel labeling requirements exist to eliminate that uncertainty and improve safety.

In this blog, we break down what OSHA electrical panel labeling really means, why it matters, the key components and clearance rules, common mistakes that lead to violations, and the best practices, tools, and resources businesses can use to stay compliant and safe.

What Does ‘OSHA Electrical Panel Labeling’ Mean?

OSHA electrical panel labeling refers to the mandatory identification and warning information applied to electrical panels to communicate hazards, circuits, and operational risks. These labels support employee awareness, safe maintenance practices, and regulatory compliance across commercial, industrial, and institutional facilities.

To understand this better, OSHA focuses on several labeling fundamentals:

-

Clear identification of electrical panels and equipment.

-

Visible warnings for energized components.

-

Accurate circuit and breaker descriptions.

-

Labels are readable under normal working conditions.

Ultimately, OSHA electrical panel labeling ensures workers can quickly understand electrical risks and act safely.

Want to make sure your labels meet industry rules and inspections? This guide shows how to ensure labels are compliant with industry regulations, so your documentation stays audit-ready and error-free.

Why Is It Essential to Follow OSHA Electrical Panel Labeling Requirements?

Following OSHA electrical panel labeling requirements is critical because electrical hazards remain a leading cause of workplace injuries. Proper labeling minimizes confusion, speeds emergency response, and ensures employees and contractors understand risks before interacting with electrical systems.

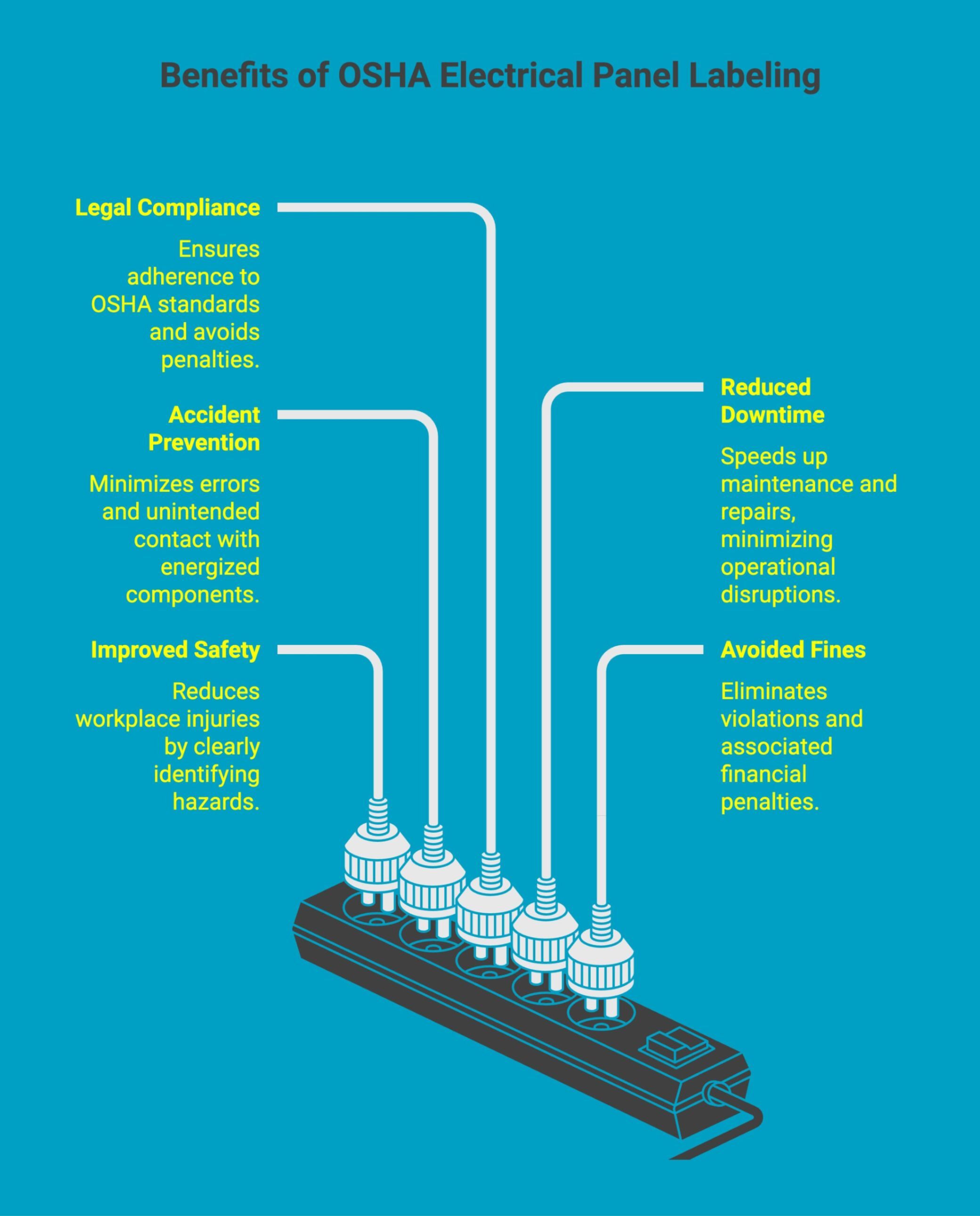

Key safety and operational benefits include:

-

Improves workplace electrical safety by clearly identifying hazards, live circuits, and shutdown points, helping workers make informed decisions before interacting with electrical panels.

-

Prevents accidents and misoperations by reducing guesswork, incorrect breaker selection, and unintended contact with energized components during routine tasks or emergencies.

-

Ensures legal and regulatory compliance by aligning panel identification with OSHA requirements, helping organizations pass inspections and audits with confidence.

-

Reduces downtime during maintenance by allowing technicians to quickly locate the correct circuits and equipment, speeding repairs and minimizing operational disruptions.

-

Avoids OSHA fines and penalties by eliminating common violations related to missing, unclear, or outdated electrical panel labeling.

Proper compliance safeguards employees, minimizes operational risk, and keeps business operations running safely and uninterrupted.

What Are the Key Components of OSHA Electrical Panel Labeling Requirements?

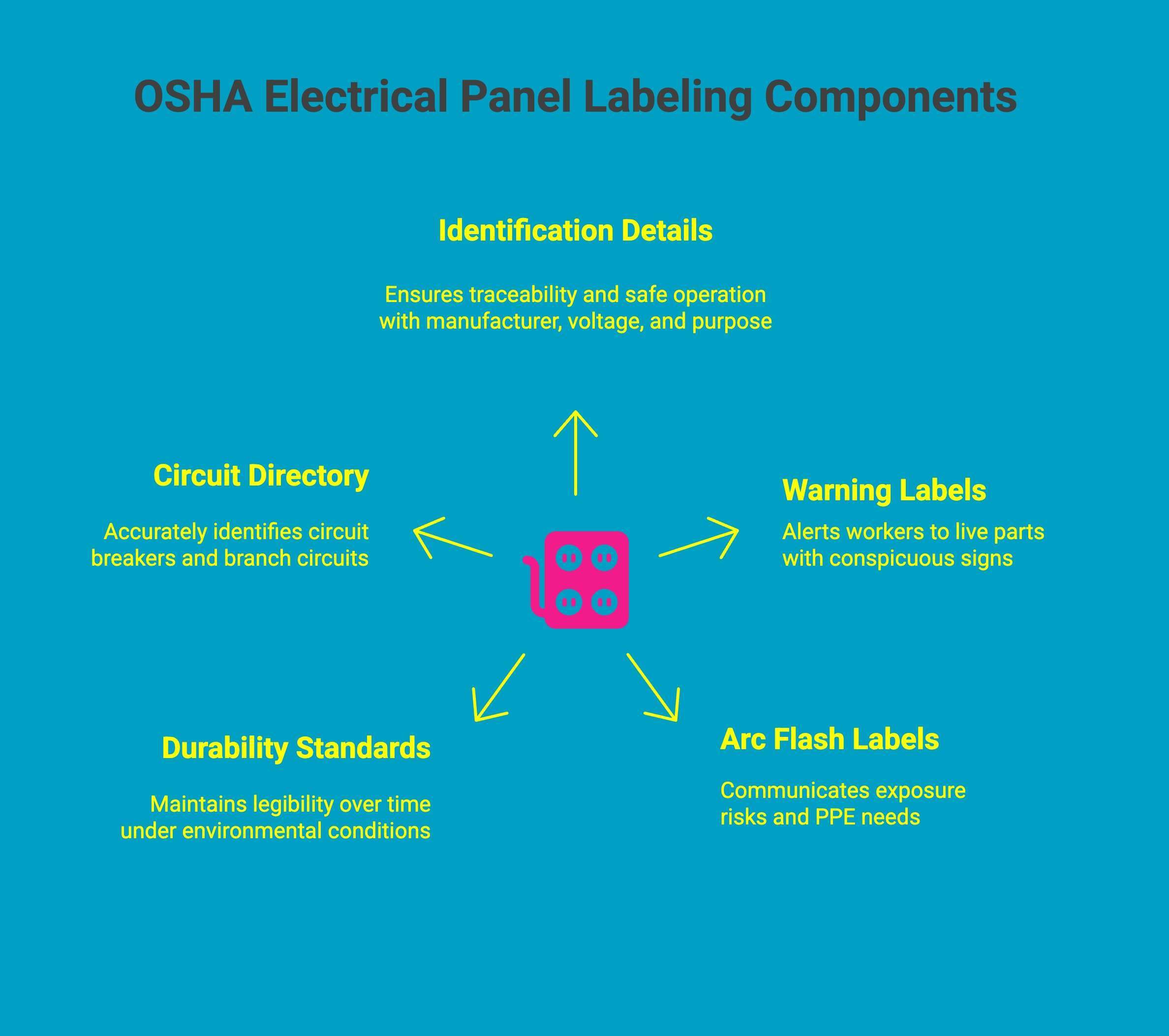

OSHA electrical panel labeling requirements define the minimum information needed to clearly communicate hazards, equipment purpose, and operational limits. These components support occupational safety by helping workers identify energized systems, understand risks, and interact with a proper electrical panel in line with health standards.

These requirements are organized into the following core components:

1. Required Identification Details

OSHA regulations require clear identification of service equipment and electrical equipment to ensure traceability and safe operation. Labels should include the manufacturer’s name, voltage ratings, and the specific purpose of use, helping reduce the risk of errors during inspection, maintenance, or emergency response activities.

2. Warning and Hazard Label Requirements

Warning labels must alert workers to live parts using conspicuous warning signs and appropriate safety signs. The wording of any sign should clearly communicate hazards, supporting workplace safety and compliance with health administration expectations across facilities in the United States.

3. Arc Flash and PPE Label Requirements

Arc flash labels communicate exposure risks and required protective measures. These labels support accident prevention tags by clearly indicating hazard boundaries and personal protective equipment needs, ensuring workers understand risks before interacting with energized systems or similar branch circuit equipment.

4. Durability and Readability Standards

OSHA expects labels to maintain sufficient durability under environmental conditions. Labels should use a white background with white lettering where required for contrast and clarity, ensuring information remains legible over time and continues to provide sufficient information for safe use.

5. Circuit Directory and Breaker Label Rules

Circuit directories must accurately identify circuit breakers and branch circuits. Labels should clearly distinguish loads, indicate similar branch circuit equipment, and help technicians isolate power safely, reducing confusion and supporting consistent compliance with workplace electrical safety expectations.

Together, these components ensure electrical panels communicate hazards clearly, remain compliant, and support long-term safety.

Learn why choosing the right labels for harsh environments matters, and how durable materials improve readability, longevity, and performance.

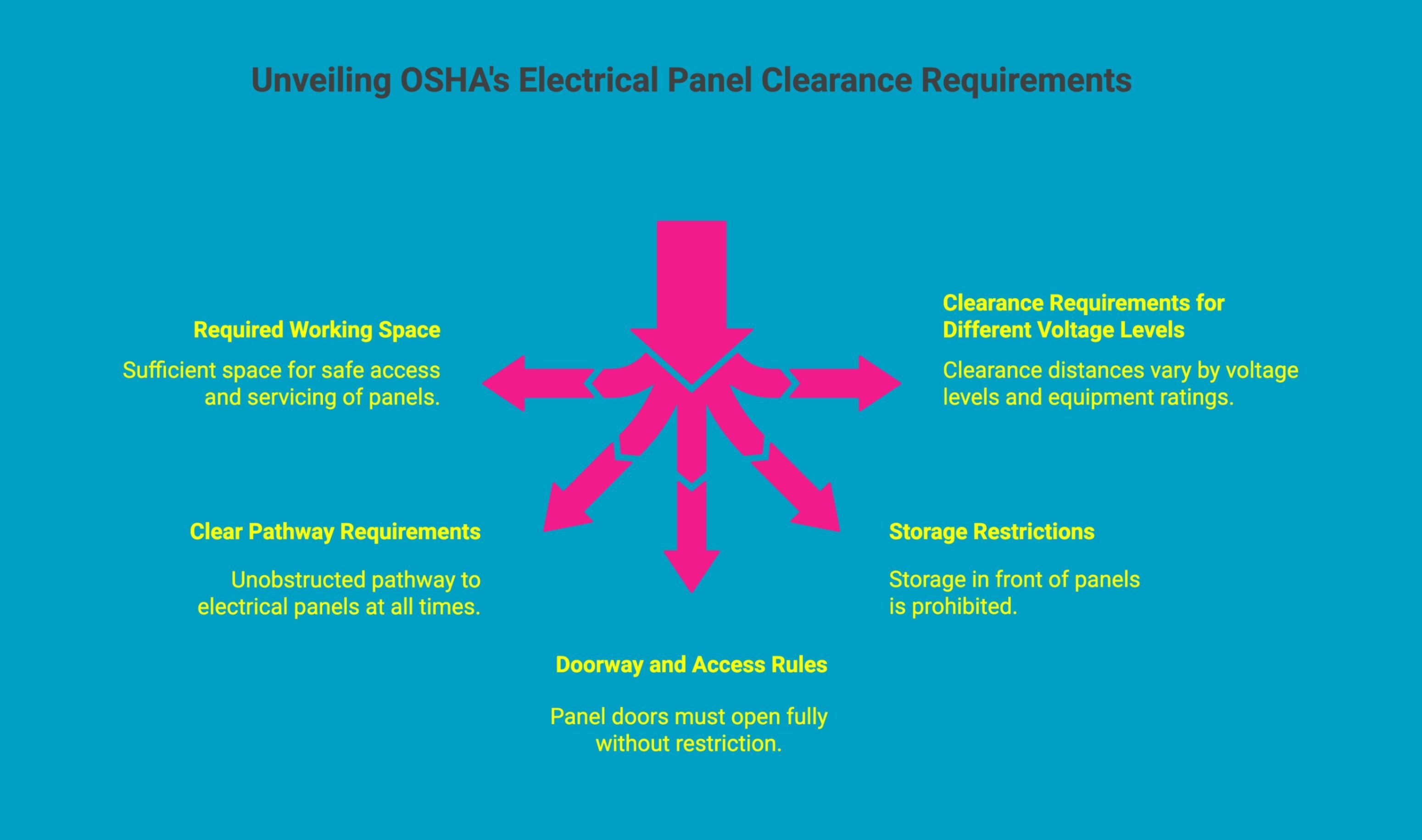

What Are OSHA’s Electrical Panel Clearance Requirements?

OSHA electrical panel clearance requirements define how much unobstructed space must be maintained around electrical panels to protect workers and equipment. These rules support safe interaction with machinery, reduce hazards near power supply sources, and align clearance practices with nationally recognized electrical safety frameworks.

OSHA outlines clearance compliance through the following requirements:

1. Required Working Space (Depth, Width, Height)

Clearances must allow safe access to panels supplying wiring, feeders, and conductors without obstruction. OSHA aligns with the National Electric Code and National Fire Protection Association guidance, ensuring sufficient space around enclosures to safely service similar branch circuit distribution equipment under normal and emergency conditions.

2. Clear Pathway Requirements

OSHA requires a clear pathway to electrical panels at all times. Safety labels, safety symbols, and a visible safety alert symbol help reinforce access rules, while safety instruction signs communicate that blocked pathways increase exposure risks and compromise electrical safety during urgent maintenance or shutdown scenarios.

3. Doorway and Access Rules

Panel access doors must open fully without restriction. OSHA discourages any negative suggestion that partial access is acceptable, requiring unobstructed entry points marked with safety notice messaging. These rules help ensure fast response when working near energized machinery or distribution systems.

4. Storage Restrictions in Front of Panels

Storage in front of panels is prohibited to prevent restricted access to markings, message panel details, and equipment specifications. Obstructions can hide maximum fault current information and interfere with compliance expectations supported by NFPA and Electrical Safety Foundation International guidance.

5. Clearance Requirements for Different Voltage Levels

Clearance distances vary by voltage levels and equipment ratings. OSHA references NFPA standards to ensure sufficient spacing based on electrical load, panel design, and system capacity, protecting workers from arc hazards while maintaining visibility of required safety markings and trademark identifiers.

Maintaining proper clearance ensures panels remain accessible, hazards are visible, and electrical systems stay compliant and safe.

Need help understanding label compliance across global standards? This resource breaks down OSHA, GHS, EU, and other regulatory requirements to help you stay compliant in any industry.

How Does OSHA Enforce Compliance for Electrical Panel Labeling?

OSHA enforces electrical panel labeling compliance through inspections, documentation reviews, and corrective enforcement actions. These processes ensure businesses properly apply electrical panel labels OSHA requires, reduce workplace hazards, and consistently osha and label electric panels in accordance with federal electrical safety expectations.

OSHA enforcement is carried out through the following mechanisms:

1. How Do OSHA Inspection and Audit Procedures Work?

OSHA conducts scheduled and unannounced inspections to verify OSHA electrical panel box labeling accuracy. Inspectors assess the visibility, placement, and condition of labels, ensuring panels clearly communicate hazards and align with OSHA electrical safety labels standards during routine operations and emergency scenarios.

2. How OSHA Issues Citations for Labeling Violations?

Citations are issued when inspectors identify missing, unclear, or incorrect labeling. Violations often involve outdated information, unreadable text, or improper placement, demonstrating failure to meet the electrical panel labels OSHA requirements designed to protect workers from electrical hazards.

3. What Are the Common OSHA Penalties and Fine Structures?

Penalties vary based on severity, repeat violations, and risk level. Minor labeling issues may result in warnings, while serious or repeated failures can trigger significant fines, reinforcing OSHA’s focus on proactive electrical hazard communication and compliance accountability.

4. How Can Employers Correct Violations?

Employers must correct violations within specified timeframes by updating labels, restoring visibility, and improving accuracy. Follow-up documentation or reinspection may be required to confirm corrective actions and ensure ongoing compliance with OSHA labeling standards.

5. What Recordkeeping and Documentation Does OSHA Require?

OSHA expects employers to maintain records of inspections, corrections, and labeling updates. Proper documentation demonstrates compliance efforts, supports audits, and helps organizations track changes to electrical systems over time.

Effective enforcement encourages consistent labeling practices, safer workplaces, and long-term regulatory compliance.

What Are the Best Practices for Labeling Electrical Panels?

Applying best practices helps organizations meet and exceed electrical panel labeling requirements OSHA sets for workplace safety. Consistent, well-designed labels improve clarity, reduce confusion, and support long-term compliance with OSHA electrical labeling requirements across inspections, training programs, and daily facility operations.

Recommended best practices include the following:

1. Use Clear, Durable Labels

Labels should remain legible in industrial environments and resist fading, moisture, and wear. Clear text, strong contrast, and durable materials ensure critical safety information stays visible, supporting compliance and reducing misinterpretation during maintenance or emergency situations.

2. Follow OSHA and NEC Guidance

Align labeling with OSHA standards and NEC references to ensure accuracy and consistency. Following recognized guidelines helps businesses meet regulatory expectations while maintaining clarity across electrical systems, inspections, and employee safety training efforts.

3. Maintain Consistent Formatting

Using consistent fonts, colors, and layout improves recognition and reduces confusion. Standardized formatting helps workers quickly identify hazards and equipment, improving response time and reinforcing safe electrical practices throughout the facility.

4. Place Labels at Eye Level

Position labels where they are easily seen without obstruction. Eye-level placement ensures workers notice warnings and identification details before interacting with electrical panels, supporting proactive hazard awareness and safer decision-making.

5. Update Labels After Changes

Any system modification should trigger label updates. Keeping labels current ensures accuracy, supports audits, and prevents errors caused by outdated or misleading information during troubleshooting or emergency response.

Strong labeling practices strengthen compliance, protect workers, and create safer electrical environments overall.

Wondering how to protect labels from water, heat, and chemicals? Discover the science behind waterproof, heat-resistant, and chemical-proof labels and what you need to choose the right materials.

What Common Electrical Panel Labeling Mistakes Lead to OSHA Violations?

Many electrical panel labeling violations happen because of routine oversights rather than deliberate noncompliance. These mistakes reduce hazard visibility, delay emergency response, and increase the likelihood of citations during inspections, especially in busy or constantly changing work environments.

The most frequent compliance mistakes include:

1. Blocked Access Around Panels

Placing equipment, storage, or furniture near panels restricts access and violates safety rules. Blocked panels slow emergency shutoffs and create dangerous working conditions during maintenance or fault situations.

2. Insufficient Clearance Dimensions

Failing to maintain the required working space around panels limits safe movement and increases exposure risk. Inadequate clearance often goes unnoticed until inspections or emergency access are needed.

3. Missing or Incorrect Labels

Panels without proper identification or warning labels leave workers guessing. Incorrect or unclear labels increase the chance of improper handling and unsafe interactions with energized systems.

4. Obstructed Exit Routes

Panels located near blocked exits or pathways compromise evacuation and emergency response. Obstructions reduce visibility and delay access when time is critical.

5. Outdated or Inconsistent Information

Changes to systems without updating labels create confusion. Inconsistent or outdated information undermines safety procedures and increases the risk of operational errors.

Avoiding these mistakes strengthens compliance and significantly reduces OSHA violation risks.

How Can Businesses Prevent These Issues?

Preventing electrical panel labeling issues requires consistent attention, proactive maintenance, and structured safety routines. When businesses make labeling part of daily operations, they reduce hazards, avoid compliance failures, and ensure workers can access and understand panel information quickly and safely.

Effective prevention strategies include the following:

1. Conduct Routine Walkthroughs

Regular inspections help identify blocked access, fading labels, missing markings, and clearance violations early. Routine walkthroughs ensure problems are corrected before inspections and reinforce ongoing compliance across all electrical areas.

2. Keep Panel Areas Clean

Maintaining clear, uncluttered spaces around panels improves visibility and accessibility. Removing storage items and debris prevents accidental obstructions and ensures panels remain safe to reach during emergencies or maintenance activities.

3. Use Highly Visible Materials

Bright, durable labeling materials improve readability and reduce miscommunication. High-contrast labels help workers identify hazards instantly, even in low-light or high-traffic areas where visibility challenges are common.

4. Educate Employees on Etiquette

Teaching employees proper panel etiquette, such as avoiding storage nearby, respecting clearance markings, and reporting damaged labels, helps maintain consistent safety practices and prevents recurring violations.

5. Clearly Mark Clearance Zones

Visible floor markings and signage around panels reinforce no-storage rules and maintain safe access paths. Clearly marked zones prevent accidental encroachment and support consistent compliance throughout the facility.

Proactive prevention helps businesses maintain safety, improve compliance, and avoid costly violations.

Looking for the perfect label printer for your business? This complete guide walks you through how to choose the right label printer based on your needs, volume, and desired results.

What Tools and Resources Can Help You Comply With OSHA Electrical Panel Labeling Standards?

Complying with OSHA electrical panel labeling standards is easier when businesses combine the right hands-on tools with authoritative reference materials. Together, these support accurate labeling, long-term durability, and readiness for inspections or audits.

What Tools Can You Use for OSHA-Compliant Electrical Panel Labeling?

These tools help teams apply, maintain, and manage compliant electrical panel labels in real-world operating environments:

-

Industrial label makers for electrical applications that produce clear, durable labels suitable for panels, wires, and enclosures.

-

OSHA-compliant label templates and software that standardize wording, layout, and formatting to reduce errors.

-

Durable label materials such as vinyl, polyester, and laminated options are designed to resist heat, moisture, and wear.

-

Lockout/tagout (LOTO) labeling systems are used to clearly mark energy isolation points during maintenance or repairs.

-

Arc-flash and electrical hazard label kits that communicate risks and required precautions near energized equipment.

-

Barcode or QR code labeling tools that support maintenance tracking, asset identification, and digital recordkeeping.

What Resources Should You Reference for OSHA Electrical Panel Labeling?

Authoritative resources help organizations interpret requirements correctly and stay aligned with current safety expectations:

-

OSHA standards (29 CFR 1910 Subpart S), defining workplace electrical safety and labeling requirements.

-

National Electrical Code (NEC / NFPA 70), providing technical guidance on electrical installations and identification.

-

NFPA 70E, which addresses electrical safety practices, hazard awareness, and worker protection.

-

Manufacturer labeling guidelines that specify proper identification for electrical equipment and components.

-

Facility safety policies and risk assessments that tailor labeling practices to site-specific hazards.

-

Local authority or electrical inspector guidance that clarifies regional enforcement expectations and interpretations.

Using well-chosen tools alongside trusted regulatory resources reduces labeling errors, simplifies inspections, and supports consistent, long-term OSHA compliance.

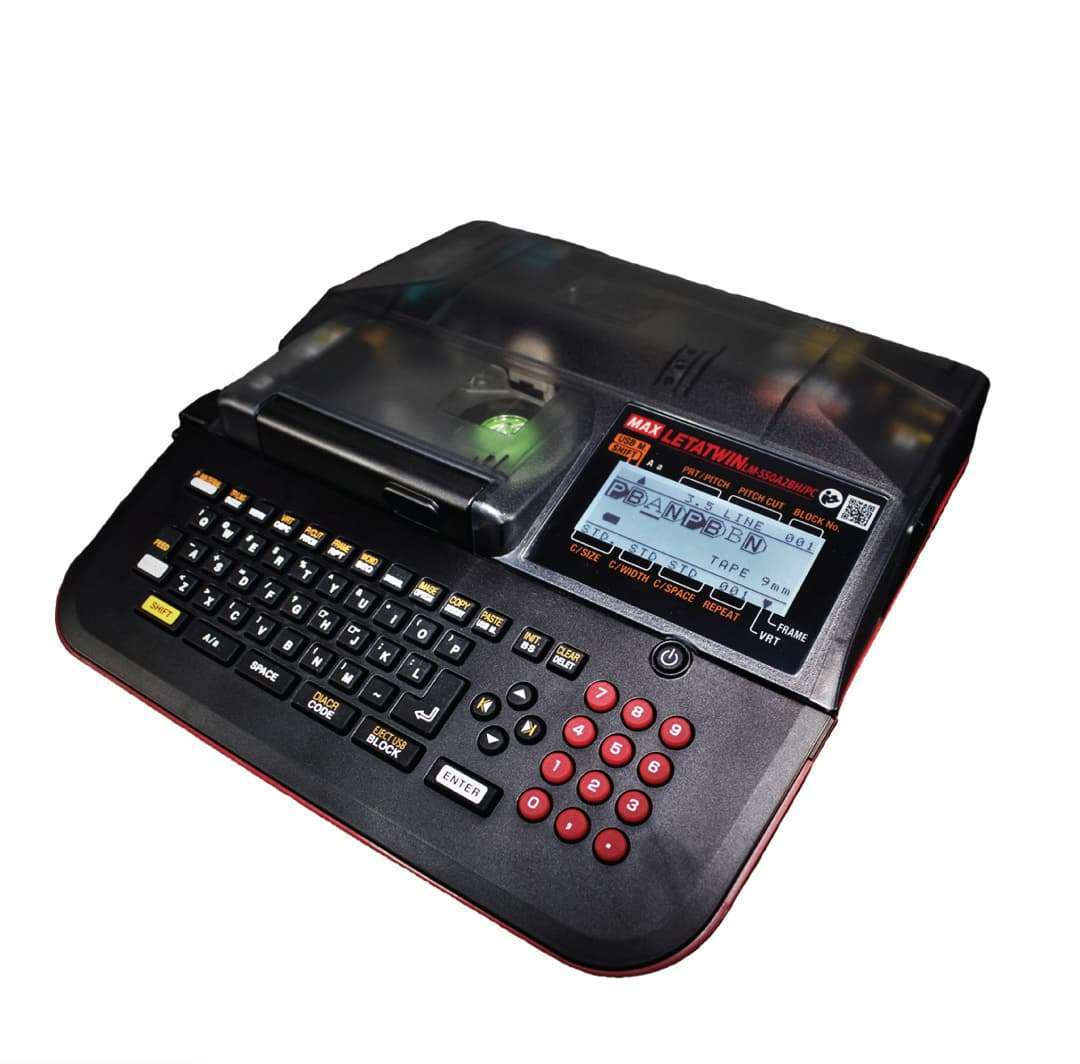

Which Label Printer Helps You Meet OSHA Electrical Panel Labeling Requirements?

Electrical labeling often fails in real-world environments, not because standards are unclear, but because labels don’t last. Fading text, peeling materials, and inconsistent formatting can quickly turn a compliant installation into a safety risk or inspection issue.

At DuraFast Label Company, we supply proven electrical labeling solutions like the MAX LETATWIN LM-550A3BH, a printer built specifically for environments where clarity, durability, and compliance matter. It supports wire markers, panel labels, and heat-shrink tubing designed to stay legible in demanding industrial conditions.

Key advantages of the printer include:

-

Labels that are easy to read at a glance, even in busy or low-light environments.

-

Materials built to withstand heat, moisture, and harsh industrial exposure.

-

Consistent formatting that keeps all labels professional and easy to understand.

-

Features designed specifically for real-world electrical and industrial labeling needs.

Using a specialized printer removes guesswork, speeds up labeling, and simplifies ongoing compliance. At DuraFast Label Company, we help you get electrical labeling right the first time. Contact us today for all your labeling needs and expert guidance.

Conclusion

OSHA electrical panel labeling requirements exist to protect workers, ensure safe electrical access, and support regulatory compliance. By applying proper labels, maintaining clearance, using durable materials, and conducting routine checks, businesses can reduce risks, avoid penalties, and maintain safer electrical environments long-term.

Frequently Asked Questions

What types of labels must be placed on electrical panels for OSHA compliance?

OSHA requires electrical panels to display identification labels, warning and hazard labels, and circuit directories. These labels help communicate electrical risks, equipment purpose, and safe access requirements to employees, contractors, and emergency responders clearly.

What information is mandatory on an electrical panel label according to OSHA?

Mandatory information typically includes panel identification, voltage levels, hazard warnings, and accurate circuit descriptions. Labels must be legible, durable, and positioned for visibility so workers can quickly understand electrical risks before interaction.

What are some common mistakes companies make with electrical panel labeling under OSHA standards?

Common mistakes include missing labels, outdated circuit directories, blocked access, insufficient clearance, and labels that fade or peel. These errors reduce hazard awareness and frequently result in OSHA citations during workplace inspections.

Does OSHA have requirements for the visibility or durability of electrical panel labels?

Yes, OSHA expects electrical panel labels to be clearly visible, legible, and durable. Labels must withstand environmental conditions without fading, peeling, or becoming unreadable, ensuring long-term safety communication within the workplace.

What are the most common electrical code violations?

Common electrical code violations include blocked panel access, missing labeling, improper clearance, overloaded circuits, and outdated equipment. These issues increase safety risks and often trigger OSHA citations during electrical safety inspections.

What are electrical safety standards, and who enforces them?

Electrical safety standards define safe installation, operation, and maintenance practices for electrical systems. OSHA enforces workplace compliance, while codes like the NEC provide technical guidance adopted by regulatory authorities.

What are the regulatory requirements for electrical panel labels?

Regulatory requirements mandate that electrical panels display identification, hazard warnings, and circuit information. Labels must remain readable, accurate, and accessible to support safe operation, maintenance, and emergency response under OSHA guidelines.

Why is electrical labeling important for electrical installations?

Electrical labeling is important because it communicates hazards, prevents accidental contact, and speeds troubleshooting. Clear labels protect workers, reduce downtime, support compliance, and improve overall safety throughout electrical installations and facilities.

Do OSHA labeling requirements differ for new versus existing electrical panels?

OSHA labeling requirements do not differ for new versus existing electrical panels. Both must be clearly labeled to identify hazards, voltage, and circuits. However, older panels may require updates to meet current standards during modifications, inspections, and audits.