What Is a Thermal Transfer Ribbon and How Does It Work?

9th Feb 2026

Key Highlights

- Thermal transfer ribbons are ink-coated films used in printers to create durable, smudge-proof, and fade-resistant labels.

- They work by transferring melted ink from the ribbon onto a label surface using controlled heat and pressure.

- The three main types of ribbons are wax (for paper labels), wax-resin (for coated or semi-synthetic materials), and resin (for harsh, industrial environments).

- Each ribbon contains three layers: a base film, an ink layer, and a backcoat, to ensure smooth operation and printhead protection.

- To choose the right ribbon, match it with your label material, consider environmental conditions, and balance performance with cost.

- Maintain print quality by cleaning your printhead, storing ribbons properly, and using correct printer settings to extend both ribbon and printer lifespan.

Printing durable, high-quality labels requires more than just the right printer. The ribbon directly influences how sharp the print looks, how well the barcode scans, and how long the label stays readable under real-world conditions.

Thermal transfer ribbons are designed to deliver consistent results across different label materials and environments, which is why selecting the correct ribbon type can significantly improve print reliability and reduce waste from reprints.

In this blog, we will explain how thermal transfer ribbons work, outline the differences between ribbon types, and guide you in choosing the best option for your specific application.

What Is a Thermal Transfer Ribbon?

A thermal transfer ribbon is essentially the “ink source” for thermal transfer printers. It is a thin film coated with a special ink layer that melts onto the label surface when heated by the printhead. If you've ever wondered how warehouses, factories, or retail stores get those sharp, long-lasting barcodes and product labels that never seem to smudge or fade, the secret behind that durability is often this thermal transfer ribbon.

Unlike direct thermal printing, which relies on heat-sensitive paper and fades over time, thermal transfer ribbons allow printing on paper, synthetic labels, and durable industrial materials, while also providing resistance against rubbing, chemicals, UV light, and harsh handling.

This is why industries like manufacturing, logistics, retail, and healthcare rely on thermal transfer ribbons for mission-critical labels, such as product IDs, shipping labels, pallet tags, compliance labels, and medical labelling, where clarity and durability are non-negotiable.

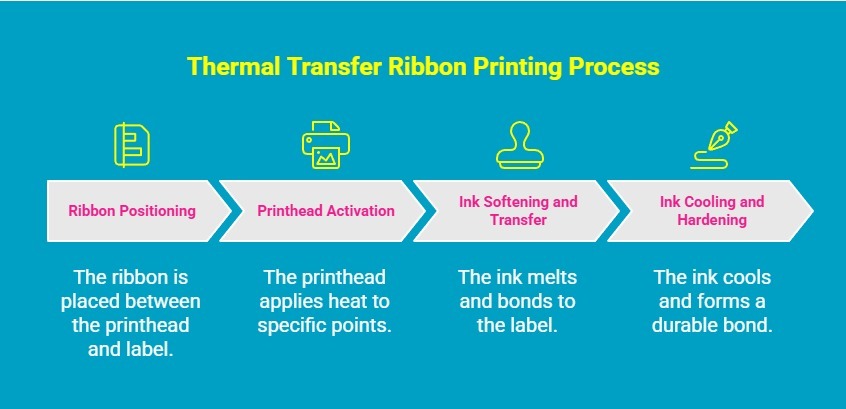

How Does a Thermal Transfer Ribbon Work?

A thermal transfer ribbon works through a controlled heat-transfer process where the printer melts the ink on the ribbon and bonds it onto the label surface. This is what enables thermal transfer printing to produce crisp barcodes, readable serial numbers, and durable identification labels that hold up in real-world environments like warehouses, production floors, and logistics hubs.

Stage 1: The Ribbon Is Positioned Between the Printhead and the Label

Inside the printer, the ribbon feeds right between the printhead and the label material. This alignment ensures the printhead can apply heat directly to the ink coating. For example, when printing shipping labels continuously on a conveyor line, this positioning keeps the ribbon and label moving in perfect sync to avoid misalignment or blurred output.

Stage 2: The Printhead Applies Heat to Specific Print Points

The printhead activates tiny heating elements only in areas where characters, barcodes, or graphics need to be printed. This precision is the reason barcodes made with thermal transfer technology can be scanned reliably, even when printed in small sizes like UPC codes on retail packaging.

Stage 3: The Ink Layer Softens and Transfers Onto the Label

When the heating elements apply heat, the ink melts and bonds to the label surface. For example, if you are printing on synthetic polypropylene labels used in chemical containers, this melted ink layer ensures the printed information does not rub off during handling.

Stage 4: The Ink Cools and Forms a Durable Bond

As soon as the label moves beyond the print point, the ink cools and hardens. This is why thermal transfer labels stay readable even after exposure to friction, temperature changes, or moisture, such as pallet labels stored in a cold warehouse or products transported across multiple handling points.

This mechanism produces consistent, high-quality prints suitable for both short-term and industrial-grade labeling needs.

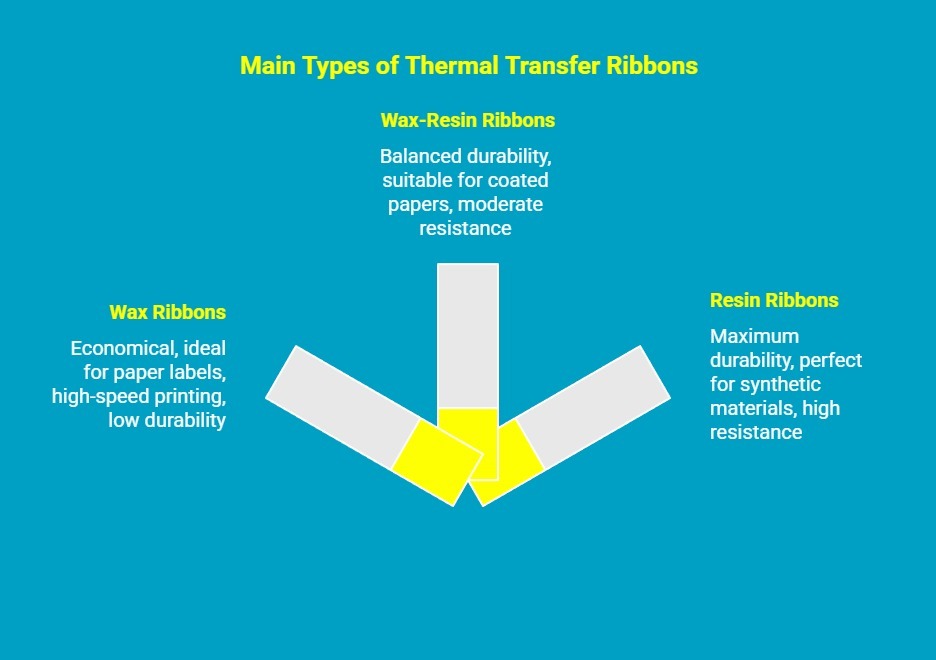

What Are the 3 Main Types of Thermal Transfer Ribbons?

Not all thermal transfer ribbons are created equal. The type of ribbon you choose directly affects your print quality, label durability, and overall printing cost. Here are three thermal transfer ribbon types commonly used:

1. Wax Ribbons

A wax thermal transfer ribbon is the most economical and commonly used type. It is ideal for printing on paper-based labels, such as shipping or retail labels. The ink is primarily made of wax, which melts easily at lower temperatures, making it suitable for high-speed printing. However, wax prints are less resistant to smudging or abrasion and are best suited for indoor, low-contact environments.

2. Wax-Resin Ribbons

Wax-resin ribbons strike a balance between print quality and durability. They contain a blend of wax and resin, allowing for greater resistance to moisture, scratches, and moderate chemicals. These ribbons work well on coated papers and some synthetic materials, making them ideal for product labeling, logistics, and semi-outdoor applications.

3. Resin Ribbons

A resin thermal transfer ribbon is designed for maximum durability and performance. The ink is fully resin-based, requiring higher printhead temperatures to transfer. The resulting prints are extremely resistant to heat, chemicals, solvents, and abrasion, perfect for synthetic materials like polyester, polypropylene, or vinyl. These industrial thermal transfer ribbons are commonly used in harsh factory environments, laboratory labeling, and outdoor applications.

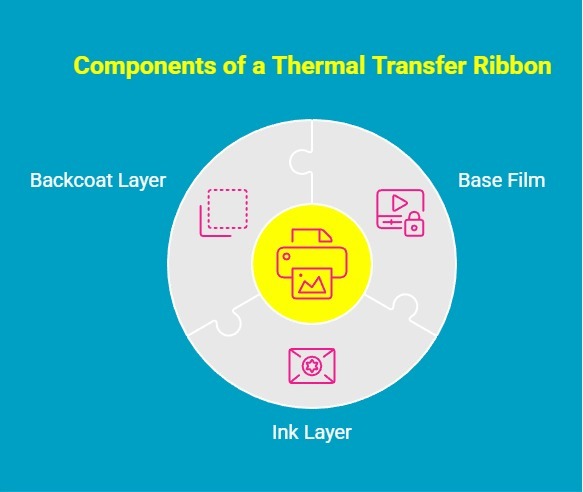

What Are the Main Components of a Thermal Transfer Ribbon?

A thermal transfer ribbon is made up of multiple layers, and each one directly impacts print quality, printer uptime, and long-term cost efficiency. Here are the main components:

1. Base Film

This polyester film acts as the structural foundation of the ribbon. It keeps the ribbon stable, maintains tension, and ensures smooth feeding through the printer. In practical terms, this means fewer ribbon wrinkles, fewer print errors, and smoother runs when printing at scale.

2. Ink Layer

This is the printable coating made of wax, resin, or a blend of both. When heated, this layer transfers the image onto your label. The formulation determines how sharp the print looks and how resistant it is to smudging, chemicals, or abrasion. In simple benefit terms: better print quality and better durability equals fewer reprints and fewer rejected labels.

3. Backcoat Layer

This is applied to the side of the ribbon that touches the printhead. It reduces static, friction, and heat buildup. The benefit to the end user: this layer helps prevent printhead damage, extends printhead life, and reduces maintenance costs over time. In other words, a high-quality ribbon with a proper backcoat directly saves money on expensive printhead replacements.

So each layer is not just a technical component. It plays a role in improving reliability, reducing downtime, and lowering the total cost of ownership..

Why the MAX Letatwin Printer Stands Out with Its Specialized Ink Ribbon Case?

Most leading barcode printers like Brother, Datamax, Godex, Printronix, Toshiba, and Zebra rely on standard thermal transfer ribbons to deliver clear, long-lasting prints on labels and tags. These ribbons, such as Brother TD4 and Titan Industrial ribbons, Datamax 360M ribbons, Godex Industrial and GE300 ribbons, Printronix ribbons, Toshiba 600m Near Edge ribbons, and Zebra ribbons, are designed for high-speed, high-volume printing. They perform exceptionally well across various substrates and applications, ensuring crisp barcodes and text that resist smudging, fading, and abrasion.

However, the MAX Letatwin Printer takes this a notch higher.

Where MAX Letatwin Is Different and Why It Matters?

While standard ribbons excel on flat labels, cable and wire marking is a very different application. The surface is round, uneven, and often tight to work with. This requires more controlled pressure, precise ink transfer, and stability, something traditional ribbon systems are not optimized for.

The Value of MAX’s Specialized Ink Ribbon Case

This is where the MAX Letatwin Printer stands out. Its specialized ink ribbon case is engineered specifically for cable and wire marking, not general label printing. The casing helps maintain consistent pressure and alignment on cylindrical surfaces such as power wires, network cables, patch cords, and control panel wiring. This results in clear, smudge-proof text that remains readable even after handling, installation, or environmental exposure.

Built-In Reliability for Industrial Use

By integrating the ribbon case into the printer itself, MAX reduces the risk of misalignment, jammed ribbon paths, and print inconsistency. For electrical contractors, panel builders, and industrial maintenance teams, this means faster labeling, fewer reprints, and dependable output in environments where clarity is safety-critical.

In short, MAX Letatwin is not just another printer using a different ribbon format. It is a solution purpose-built for wire and cable identification, and that specialization is what gives it a performance advantage in industrial, electrical, and networking applications.

Where Are Thermal Transfer Ribbons Most Commonly Used?

Thermal transfer printing ribbons are widely used across industries that require long-lasting, high-contrast labels capable of withstanding heat, moisture, or abrasion. Their versatility and print durability make them suitable for both paper and synthetic labels. Here are some of the most common use cases:

- Manufacturing and Warehousing: For product identification, barcodes, and inventory tracking labels that must remain readable throughout production and storage.

- Retail and Logistics: For shipping labels, shelf tags, and carton labeling, where smudge-resistant and scannable prints are essential.

- Healthcare and Laboratories: For specimen labels and medical equipment tagging that can endure sterilization, chemicals, or cold storage.

- Electronics and Automotive: For component and circuit labeling that resists high temperatures and exposure to solvents.

- Outdoor and Industrial Environments: For durable labels used in construction materials, chemical containers, and industrial machinery.

In short, wherever label readability and durability are critical, thermal transfer ribbons are the go-to printing medium.

How to Choose the Right Thermal Transfer Ribbon for Your Application?

Selecting the right thermal transfer ribbon is essential for achieving optimal print quality, label durability, and cost efficiency. The wrong ribbon can lead to smudged prints, fading, or premature label failure. Below are the three key factors to consider when making your choice:

Step 1: Match Ribbon to Label Material

Each ribbon type is designed for specific label materials. Choosing a mismatched combination can result in poor adhesion or inconsistent print quality.

- Use wax ribbons for matte or uncoated paper labels.

- Use wax-resin ribbons for coated papers or light synthetics.

- Use resin ribbons for fully synthetic materials like polyester or polypropylene.

Step 2: Consider Environmental Conditions

The environment where your labels will be used greatly impacts ribbon performance.

- For indoor, low-contact uses, wax ribbons are cost-effective and sufficient.

- For semi-outdoor or industrial conditions, wax-resin ribbons offer enhanced resistance to smudging and moisture.

- For extreme environments involving heat, chemicals, or abrasion, resin ribbons deliver maximum durability.

Step 3: Balance Cost and Performance

Higher-grade ribbons provide better resistance and longevity but come at a higher cost. Evaluate your operational needs before deciding.

- Wax ribbons are ideal for short-term or high-volume applications.

- Wax-resin ribbons balance affordability with durability.

- Resin ribbons are a premium choice for long-lasting, high-resistance labeling.

By aligning the ribbon type with your label material, environment, and durability needs, you can ensure consistent print quality, extended label life, and reduced reprints. Want to know how durable your labels are? Here is a guide to generating long-lasting print.

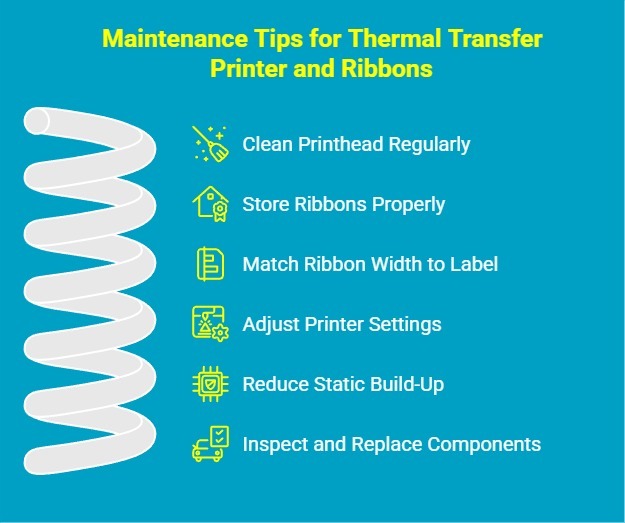

How Can You Maintain Print Quality and Extend Ribbon Performance?

Proper maintenance of your thermal transfer printer and ribbons ensures consistent print quality, minimizes downtime, and extends the life of your printhead. Here are some best practices to follow:

Maintaining your thermal transfer ribbons and printer correctly does more than improve print clarity. It helps reduce reprints, protects your printhead investment, and keeps your labeling process running smoothly without interruptions. Here are the key maintenance practices to focus on:

1. Clean the Printhead Regularly

Over time, dust, label adhesive, and ink residue can build up on the printhead surface. This leads to weak print density, streaks, and uneven barcode lines. Cleaning the printhead frequently with approved cleaning wipes or alcohol swabs keeps the print surface clear, preserves heat distribution, and reduces premature printhead wear.

2. Store Ribbons in a Controlled Environment

Ribbons can degrade if exposed to heat, humidity, or direct sunlight. Storing them in a cool and dry space keeps the ink coating stable and prevents it from softening or sticking to the film before use. Proper storage reduces waste and ensures the ribbon performs as expected from the very first label.

3. Match Ribbon Width to Label Width

A thermal transfer printer ribbon should always be slightly wider than the label being printed. This prevents the edges of the label from coming into direct contact with the printhead surface and helps avoid scratches or abrasions. This simple step can extend printhead life significantly and improve edge sharpness on printed text.

4. Adjust Printer Settings Based on Ribbon Type

Each ribbon formulation, such as wax, wax-resin, or resin, requires different heat and speed settings. Lower heat works best for wax ribbons, while resin ribbons often require higher temperatures. Using the correct settings prevents smudging, reduces wasted labels, and delivers more consistent print density.

5. Reduce or Prevent Static Build-Up

Static electricity can attract dust and particles that stick to the ribbon and damage the printhead. In dry environments, using anti-static measures, humidity control, or grounded equipment helps maintain stable ribbon performance and reduces the risk of contamination.

6. Inspect and Replace Wear Components on Time

Printers have consumable parts like rollers and printheads that naturally wear down. Regular inspection allows early detection of flat spots, alignment issues, or pressure inconsistencies. Replacing worn parts on schedule maintains proper contact between ribbon and label, ensuring consistent and accurate printing.

Following these maintenance tips ensures optimal ribbon performance, consistent print clarity, and extended printer longevity, keeping your labeling process efficient and cost-effective.

Where Can I Buy Quality Thermal Transfer Ribbons Online?

If you want reliable, premium thermal transfer ribbons that are guaranteed to perform, DuraFast is the destination professionals trust. We do not just offer ribbons. We supply genuine, high-grade wax, wax-resin, and resin ribbons engineered for industrial environments and compatible with top printer brands.

From paper to polyester to polypropylene label applications, every ribbon we sell is selected for crisp print clarity, rub resistance, chemical durability, and long-term readability. At DuraFast, you are not guessing your way through ribbon options. You are buying from experts who live and breathe industrial printing.

Final Thoughts

Thermal transfer ribbons might seem like a small part of your printing setup, but they make a big difference in print quality, durability, and overall operational efficiency. Understanding the right type of ribbon for your label material and environment ensures that your prints stay sharp, scannable, and long-lasting. You can instantly achieve consistent, professional-grade results across all labeling needs. Whether it’s product packaging, inventory tracking, or industrial labeling, a well-matched thermal transfer ribbon ensures every print stands the test of time.

Frequently Asked Questions

What is thermal transfer ribbon?

A printer ribbon is a thin film coated with ink, usually wax, resin, or a mix of both, that transfers printed images or text onto labels or tags using controlled heat and pressure from the printhead.

Are thermal transfer ribbons compatible with all label materials?

Compatibility depends on both the ribbon and label material. Wax ribbons suit paper, wax-resin works with coated labels, and resin ribbons are ideal for synthetic or durable industrial labeling applications.

Can I use a direct thermal label in a thermal transfer printer?

It’s possible, but not advisable. Direct thermal labels aren’t designed for use with ribbons and may lead to poor-quality prints, smudging, or even premature printhead wear and damage.

Do thermal transfer printer ribbons need to match?

The ribbon should match both your printer type and label material to ensure proper ink transfer, consistent print quality, and long-term durability in different usage environments.

What are thermal transfer ribbons used for?

They’re used to produce high-quality, long-lasting barcodes, product labels, and tags across industries like manufacturing, logistics, retail, and healthcare, where durability and readability are essential.

How long does thermal transfer ribbon last?

Thermal transfer ribbons typically last 12 to 24 months when stored correctly. They should be away from direct sunlight, moisture, and excessive heat to prevent ink degradation and ensure consistent print quality.

How do I install or replace a thermal transfer ribbon in my printer?

Open the printer cover, remove the used ribbon, and load the new roll as directed. Place it between the supply and take-up spools. Tighten it evenly before closing the cover and printing.

What is the thermal transfer ribbon price?

The price of thermal transfer ribbons varies based on size, material type (wax, wax-resin, or resin), and brand. On average, they range from $10 to $40 per roll, with high-performance options or color thermal transfer ribbon costing slightly more.