What Should You Know About UL Certified Wire and Cable?

11th Feb 2026

Key Highlights

-

UL-certified wires are rigorously tested to withstand heat, stress, and electrical loads safely.

-

Check the UL mark and cable-jacket labels (per the UL marking guide) to verify authentic certification.

-

UL-listed wiring meets building codes for residential and commercial installations.

-

UL standards (UL 83, UL 44, UL 4703, etc.) cover everything from THHN building wire to PV solar and fire-alarm cables.

-

UL-certified cables ensure long-term reliability with proven durability, flame resistance, and insulation integrity.

-

Marking tools like the MAX LETATWIN LM-550A3BH support UL-compliant, durable wire identification.

Wiring a home, office, or industrial project comes with high stakes, mistakes can lead to overheating, fire hazards, or costly downtime. Many people struggle with choosing the right wire and cable, wondering if it’s truly safe and reliable. That’s where UL certified wire and cable comes in, taking the guesswork out of electrical safety.

Without proper certification, even seemingly sturdy wiring can fail under heat, stress, or long-term use. From residential renovations to large commercial builds, knowing your wiring meets strict safety and performance standards is essential for peace of mind, regulatory compliance, and long-lasting results.

This blog will walk you through what UL certification means, why it matters, the key standards, and how to identify genuine UL-listed wire and cable for safe, code-compliant installations.

What is UL Certified Wire and Cable?

UL-certified wire and cable means the product has been independently tested by Underwriters Laboratories to verify that it meets strict safety and performance standards. These tests go far beyond a simple “safe to use” claim, they measure how the wire performs under real-world stress.

A UL certification confirms that the wire has been evaluated for critical factors such as:

-

Flammability: How the insulation behaves in a fire and whether it self-extinguishes.

-

Temperature rating: How much heat the conductor and insulation can safely withstand.

-

Voltage rating: Maximum operating voltage the cable can handle without breakdown.

-

Insulation integrity: Resistance to cracking, moisture, abrasion, and aging.

-

Mechanical durability: Performance under bending, pulling, and installation stress.

When you see the UL mark printed on the cable jacket, it indicates the product meets the applicable UL standard (such as UL 83 for THHN/THWN-2 or UL 4703 for PV cable). The required markings on the jacket follow UL’s official identification guidelines, helping you confirm authenticity at a glance.

Many products also carry CSA certification, which means the cable complies with both U.S. and Canadian safety requirements, useful for cross-border or multinational installations.

In short, UL-certified wiring gives you verified safety, documented performance, and code-compliant reliability, whether you’re working on residential, commercial, or industrial projects.

Why UL Certification Matters In Commercial And Residential Projects?

UL certification is essential because it ties directly to safe performance and NEC code compliance. A UL-certified cable is tested to ensure it can withstand real electrical and environmental demands without becoming a hazard.

UL testing helps prevent issues such as:

-

Cable overheating in high-load circuits

-

Insulation breakdown under heat, bending, or installation stress

-

Flame spread during fault conditions

-

Voltage failure caused by poor materials or construction

For professionals, UL-listed wiring offers:

-

Faster, smoother inspection approvals

-

Clear alignment with NEC requirements and recognized UL standards

-

Reduced liability and installation errors

For homeowners and building owners, UL certification means:

-

Lower risk of electrical failures and fire hazards

-

Confidence that wiring meets verified safety and performance criteria

Using uncertified wire increases the likelihood of overheating, conductor impurities, and insulation failure, problems that can lead to costly or dangerous outcomes. UL’s required markings help ensure each cable is correctly identified and properly installed.

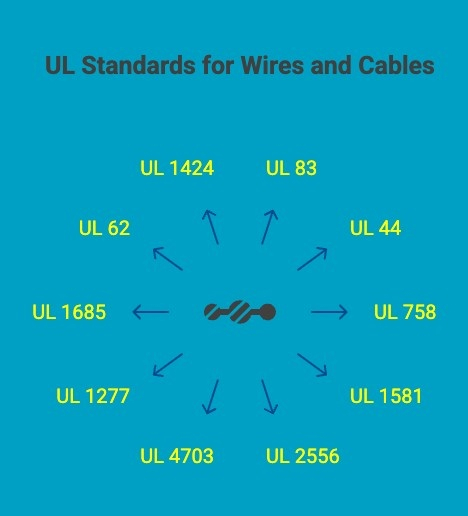

What are the Key UL Standards for Wire and Cable?

UL standards exist to define how different types of wire and cable should perform under heat, electrical load, fire, and environmental stress. Knowing these standards helps you choose the right cable, ensure NEC compliance, and reduce real-world risks like overheating, insulation failure, or fire propagation.

Major UL standards include:

-

UL 83 – Thermoplastic-Insulated Wires and Cables: Covers common building wires like THHN and THWN; essential for everyday branch-circuit wiring.

-

UL 44 – Thermoset-Insulated Wires and Cables: For rubber-like, heat-resistant insulation (e.g., XHHW), suited to harsher environments.

-

UL 758 – Appliance Wiring Material (AWM): Governs internal wiring for appliances, tools, and HVAC units.

-

UL 1581 – Reference Standard: The testing “playbook” for flame, heat, bending, sunlight, and durability; referenced by many other UL standards.

-

UL 2556 – Wire and Cable Test Methods: Defines how to measure insulation quality, electrical integrity, and mechanical strength.

-

UL 4703 – Photovoltaic (PV) Wire: Ensures PV cables withstand UV, heat, and high-voltage outdoor conditions.

-

UL 1277 – Electrical Power and Control Tray Cables (TC): For industrial tray cable systems; ensures mechanical and fire-resistance performance.

-

UL 1685 – Vertical-Tray Fire-Propagation and Smoke Test: Evaluates flame spread in tray systems.

-

UL 62 – Flexible Cords and Cables: Covers extension cords, power cords, and other movable cables.

-

UL 1424 – Power-Limited Fire-Alarm Cables: Specifies safety requirements for low-voltage fire-alarm wiring.

Understanding these standards lets you select the right cable for each application with confidence, ensuring safety, durability, and compliance across residential, commercial, and industrial projects.

What Are the Key Benefits of Using UL-Certified Wire and Cable?

Choosing UL certified wire and cable gives you way more than just a working product, it gives you peace of mind!

The biggest benefit is knowing the wire has been verified for performance and safety for wire and cable, so you’re not guessing about safety or quality. Every product goes through rigorous evaluation for things like heat performance, insulation strength, fire resistance, and long-term durability.

Because UL wire and cable is verified by an independent safety organization, it’s easier to trust that what you’re installing will hold up under real-world conditions.

Next, let’s take a closer look at the specific benefits that make UL-listed wiring such a smart choice for any project:

1. Enhanced Safety and Fire Protection

Using UL certified wire and cable dramatically reduces the risk of electrical hazards!

Every product is tested for flame resistance, overheating, and insulation integrity, ensuring it performs safely even under demanding conditions.

This is one of the biggest reasons electricians and inspectors trust UL wire and cable on both residential and commercial jobs.

2. Verified Quality and Performance

As UL certification requires strict compliance with recognized UL standards for wire and cable, you know the product has been pushed, stressed, and evaluated in controlled testing environments.

That means you’re installing wiring that consistently delivers the performance it promises.

3. Compliance With Industry and Regulatory Requirements

Local building codes, inspectors, and project specifications often expect or require UL listed wire and cable.

Choosing products that follow UL guidelines, and that are easy to interpret using the UL wire and cable marking and application guide, helps ensure your project passes inspections without delays.

4. Increased Reliability and Long-Term Durability

UL testing looks at how a cable holds up over time, not just on day one. From heat and moisture exposure to mechanical stress, UL-standard wire and cable is designed to last.

This long-term durability is especially important in commercial environments and critical residential systems where failure simply isn’t an option.

By choosing UL-certified wiring, you’re investing in consistent performance, reduced maintenance, and peace of mind, knowing that the cables will continue to operate safely and efficiently throughout their lifespan.

What is The Difference Between UL Listed and UL Recognized Cables?

When working with UL-certified wire and cable, you may encounter two different labels: UL Listed and UL Recognized. Both indicate that UL has evaluated the product, but they serve distinct purposes:

-

UL Listed cables are tested as complete, end-to-end products for general use. They meet full UL standards and are suitable for direct installation in residential, commercial, or industrial projects.

-

UL Recognized components are intended for use as part of a larger system or product. They are evaluated for safety in specific applications but are not considered standalone products.

Here’s a quick comparison table:

|

Feature |

UL Listed Cable |

UL Recognized Cable |

|---|---|---|

|

Use |

Complete product ready for installation |

Component of a larger product or system |

|

Testing |

Full UL testing per applicable wire and cable standards |

Tested for specific safety properties within a system |

|

Marking |

UL Listed symbol and application info; meets field labeling requirements |

UL Recognized component symbol; intended for incorporation into a final product |

|

Application |

Residential, commercial, industrial, and code-compliant installations |

Appliances, machinery, control panels, or assemblies |

|

NEC/Code Compliance |

Meets NEC code requirements for building and commercial wiring |

Compliance relies on integration into a UL-approved system |

|

Typical Industries |

Construction, electrical contracting, commercial buildings |

Manufacturing, industrial automation, equipment assembly |

|

Example |

THHN/THWN building wire |

Wire used inside a motor or control panel |

Understanding the difference between UL Listed and UL Recognized cables ensures proper selection, safe installation, and compliance with code and industry standards, reducing the risk of failures or inspection issues.

What Are The Different Types Of UL Certified Wires And Cables?

UL certified wire and cable comes in a variety of types, each designed for specific applications. From residential homes to industrial plants, and even specialized systems like solar or fire alarms, choosing the right type ensures safety, reliability, and compliance with UL standards for wire and cable.

Here’s a breakdown of the main categories:

1. Building & Residential Wiring

These wires are designed for everyday home and building applications:

-

THHN / THWN Building Wire: Standard thermoplastic wires used in walls and conduit for general power distribution.

-

XHHW and Other Thermoset Building Wires: Heat- and moisture-resistant wiring for more demanding environments.

-

NM-B (Nonmetallic-Sheathed Cable): Commonly used for indoor residential wiring, easy to install in walls and ceilings.

-

UF-B Underground Feeder Cable: Designed for direct burial, perfect for outdoor or underground circuits.

2. Industrial & Commercial Wiring

These cables are built for tougher, higher-load environments:

-

MC Cable (Metal-Clad Cable): Rugged wiring with metal sheathing for industrial and commercial spaces.

-

Tray Cable (TC / TC-ER): Ideal for cable trays and exposed runs in factories or large buildings.

-

Control and Instrumentation Cable: Specialized cables for controlling machinery and transmitting data in industrial settings.

3. Low-Voltage & Life-Safety Cables

These cables support critical systems that keep buildings safe and connected:

-

Fire Alarm Cable (FPL, FPLR, FPLP): UL-listed wires designed to maintain operation during a fire.

-

Communications/Data Cable (CM, CMR, CMP): For networking, phone lines, and data transmission.

-

Coaxial Cable: Often used for video, internet, and broadband connections.

4. Specialty Application Cables

Specialized UL-certified wires for unique environments:

-

PV Solar Wire (PV Wire): Sunlight and weather-resistant wires for photovoltaic solar installations.

-

Flexible Cords and Power Cords: Portable, bendable cables for tools, appliances, and equipment.

Selecting the right UL-certified wire or cable ensures safe, code-compliant installations tailored to each environment. Proper choice not only prevents failures and hazards but also supports long-term reliability, regulatory compliance, and optimal system performance.

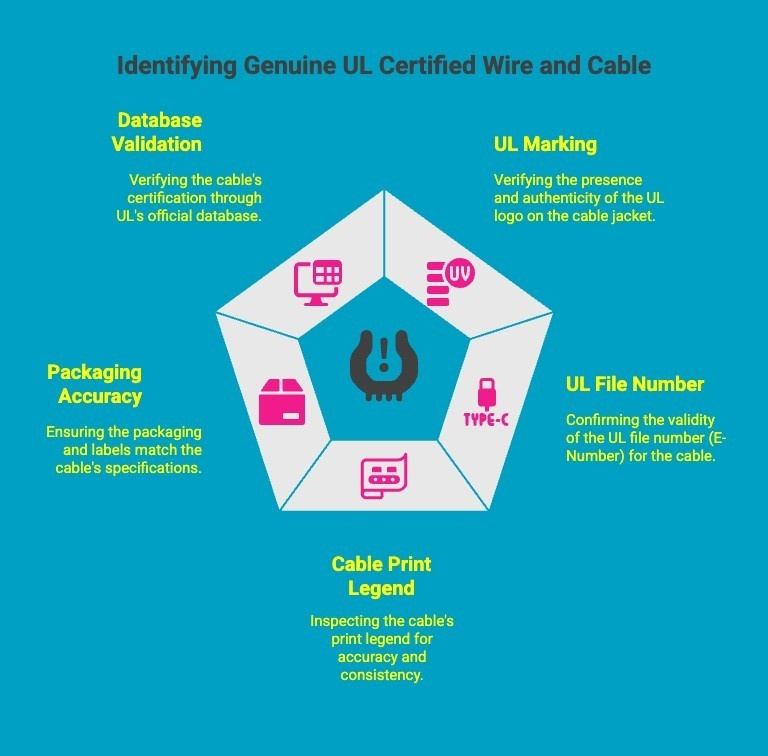

How To Identify Genuine UL Certified Wire And Cable?

Choosing UL certified wire and cable is smart, but how do you know it’s real?

There are simple ways to check, ensuring you get safe, reliable products that meet UL standards for wire and cable.

Here’s a quick guide:

1. Check the UL Marking on the Cable Jacket

The easiest way to spot genuine UL-certified wire is by inspecting the jacket. Look for the UL mark, usually a circle or square with “UL” inside. It confirms the wire or cable meets recognized UL wire and cable standards.

2. Verify the UL File Number (E-Number)

Most UL-certified wires come with a unique E-number. This file number links directly to UL’s records, letting you confirm that the manufacturer and product have been officially tested and approved according to UL standards for wire and cable.

3. Inspect the Cable Print Legend

The print legend on the cable jacket provides key info: voltage rating, insulation type, temperature rating, and certification symbols.

Cross-checking this against the UL labeling guide ensures the product is genuinely UL listed and safe for your application.

4. Confirm Packaging and Label Accuracy

Authentic UL-certified wire and cable comes with proper packaging, including labels, batch numbers, and manufacturer info.

Mismatched or missing labels can be a red flag, so always confirm everything aligns with UL wire and cable marking and application guide instructions.

5. Validate Certification Through UL’s Database

UL maintains an online database where you can verify products.

Enter the E-number, product name, or manufacturer to confirm the wire or cable is truly UL certified, giving you confidence that your installation meets recognized safety and performance standards.

How Does the MAX LETATWIN LM-550A3BH Printer Support UL-Compliant Wire Labeling?

Clear, durable labeling is essential when building UL-compliant wire and cable assemblies or control panels. The MAX LETATWIN LM-550A2BH/PC Tube and Tape Printer (LM91352) from DuraFast Label Company delivers high-quality, long-lasting labels for wires, cables, and components, ensuring critical information, like part numbers, warnings, or voltage ratings, remains legible for the life of the product.

For UL compliance, legible and permanent markings aren’t just helpful, they are often required by code.

With DuraFast Label Company's advanced software, you can design and print custom markers that withstand heat, abrasion, and daily wear, making traceability easy for inspectors, electricians, and maintenance teams.

For complex systems or large projects, the MAX LETATWIN LM-550A3BH ensures your wiring is organized, professional, and fully aligned with UL identification standards, supporting safety, efficiency, and long-term compliance.

Ensure your wiring meets UL standards and remains easy to identify and maintain. Contact DuraFast Label Company today to learn how the MAX LETATWIN LM-550A3BH can support your project!

Conclusion

When it comes to wiring your home, office, or industrial project, cutting corners isn’t an option, and that’s exactly why UL certified wire and cable matters. From safety and fire resistance to long-term reliability, UL certification ensures every product has been validated according to UL requirements for wire and cable.

Whether you’re a homeowner, contractor, or engineer, choosing UL-listed wiring means you’re installing products you can trust to perform under real-world conditions.

With clear markings, code compliance, and a variety of options for residential, commercial, and specialty applications, UL-certified wire and cable gives peace of mind from day one and for years to come.

In short, it’s more than wiring, it’s reliability, safety, and confidence you can see.

Frequently Asked Questions

How do I choose the right UL wire and cable for my project?

Select certified cable based on voltage, amount of current, insulation, and environmental factors. Use UL Solutions guide information, follow ul listing safety standards, consider cable tray use, and review product information to avoid lot of confusion across the supply chain.

What are the basic specifications for UL listed wire and cable?

UL listed cable products include voltage, insulation, temperature limits, environmental impact, and unique identifier style numbers. These safety standards follow the national electrical code, safety science principles, and UL Solutions guidance to ensure compatibility across global markets and a sustainable world.

What is the process for manufacturers to get UL certification for their wires and cables?

A cable manufacturer submits designs for cable testing, environmental impact review, and rigorous testing. UL Solutions performs audits, quality assurance checks, and evaluates international standards before granting ul recognition for standalone products used in the cable industry and international markets.

How do I identify UL certification markings on wires and cables?

Look for the UL symbol, ul listing number, style code, and manufacturer ID. These markings offer a direct link to UL Product IQ, allowing users to access UL certification data and verify safety science compliance for certified cable installations.

Where can I find comparison charts for different UL certified wires and cables?

Use UL Solutions Project Files, UL Product IQ, and other online sources offering digital tools, business information, and valuable information. These platforms help compare environmental factors, cable tray use requirements, and international standards influencing cable products across global markets.

How can I choose the right UL certified wire or cable for my application?

Match ul listing specifications with environmental factors, extreme temperatures, and application needs. Review product information, UL Solutions best practices, and sustainability challenges to ensure the certified cable performs reliably and meets the national electrical code across the supply chain.

Are there different UL certification types for hook-up and lead wires?

Yes. UL Solutions assigns style numbers defining insulation, cable testing requirements, and safety standards. These categories prevent lot of confusion by clarifying broader term classifications for international markets, environmental impact considerations, and standalone products in the cable industry.

What Are UL, CSA, and CE Markings?

UL, founded by William Henry Merrill, represents US safety science; CSA certifies Canadian consumer goods; CE supports European international standards. Together, these markings help ensure cable products remain compliant across global markets with consistent safety expectations.

Do the style numbers for Appliance Wiring Material (e.g., 1015) have any significance?

Yes. Style numbers act as a unique identifier defining insulation, environmental impact, voltage, and cable testing rules. These UL Solutions classifications provide valuable information for selecting wiring that meets international standards and supports a sustainable world.

How Does UL Certified Products Differ From Non-Certified Options?

UL certified cable undergoes rigorous testing, quality assurance checks, and UL Solutions evaluation. Non certified items may fail under extreme temperatures, lack product information, and ignore safety standards, creating risks in the supply chain and broader international markets.