How to Do Wire Printing the Right Way?

16th Jan 2026

Key Highlights

- Wire printing ensures wires are clearly labeled for safety, efficiency, and compliance across industrial applications.

- Common methods include inkjet, thermal transfer, laser marking, and hot stamping, each suited to different needs.

- Choose your method based on wire material, environment, production scale, and durability requirements.

- Top printers like the Epson LW-PX700, LW-PX400, and LW-PX900 deliver fast, durable, and precise results.

- Custom printed wire labels offer a professional finish and durability for large or complex projects.

- Follow best practices like surface cleaning, consistent formatting, and material-specific printing for lasting results.

- DuraFast Label Company offers premium wire printers, custom labels, and expert support trusted across Canada.

Ever spent hours tracing unlabeled wires just to find the right connection? In industries like electronics, aerospace, or cable manufacturing, unclear markings can cause confusion, errors, and costly downtime.

That’s where wire printing makes all the difference, ensuring every wire is clearly identified, easy to track, and ready for efficient installation.

The challenge lies in choosing the right printing method. Some inks fade under heat, some smudge with handling, and others simply don’t last. Selecting the wrong one can lead to wasted materials and inconsistent results.

In this blog, you’ll learn how wire printing works and which methods deliver the most reliable, long-lasting results for your specific needs.

What Is Wire Printing and Why Does It Matter?

Wire printing isn't just about organization; it’s about clarity and safety. In complex systems like data centers or control panels, every wire plays a critical role. Without clear labels, a quick repair can turn into hours of confusion or costly mistakes.

Proper wire printing keeps cables easy to identify, speeds up maintenance, and reduces errors. It also supports compliance and ensures labels stay readable under heat, chemicals, and wear, keeping operations smooth and reliable.

When choosing an electrical wire label printer, it’s worth paying attention to a few key features:

- Thermal transfer technology: Produces durable, smudge-proof, and UV-resistant labels.

- Portability: Lightweight, battery-powered models are perfect for fieldwork or on-site installations.

- Connectivity: Bluetooth-enabled printers with intuitive mobile apps make labeling fast and seamless.

- High resolution: A 300 dpi print head ensures crisp text, barcodes, and serial numbers.

In short, wire printing matters because it keeps your projects organized, your systems compliant, and your workflow running smoothly, regardless of the setup's complexity.

Looking to upgrade your labeling process? Get a label quote and start creating clear, durable wire labels that last.

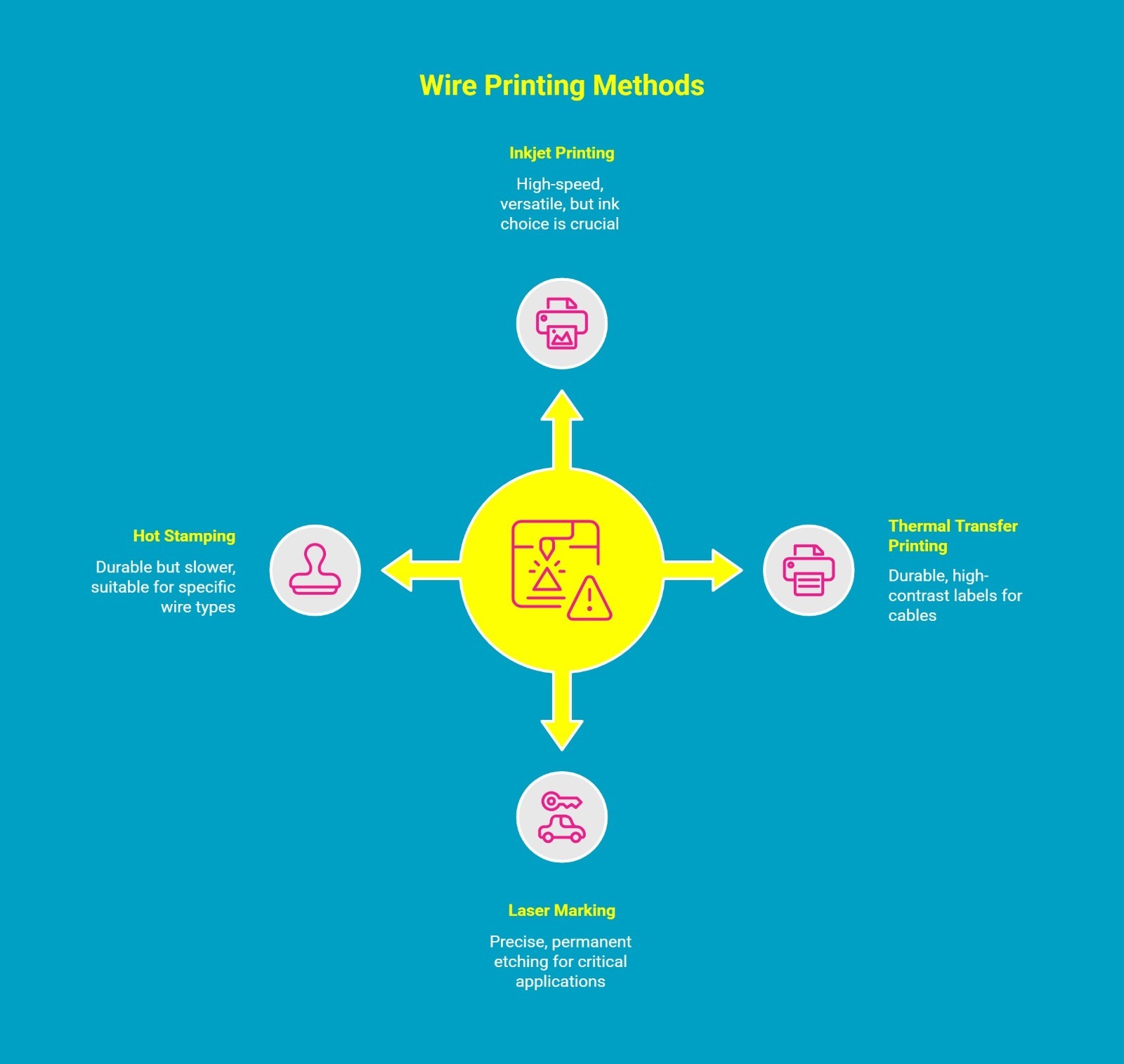

What Are the Main Wire Printing Methods Used Today?

Wire printing has evolved far beyond simple labeling tapes. Today’s methods are designed for speed, durability, and adaptability to different wire materials and environments.

The right printing technique depends on your production scale, wire type, and long-term performance requirements. Here are the main methods used across industries:

1. Inkjet Printing

Inkjet wire printing is one of the most versatile and widely used methods. It’s ideal for high-speed production lines as it can print directly on moving wires without halting the process.

Inkjet systems offer excellent readability and flexibility in font size and spacing. However, the ink must be chosen carefully to ensure it adheres well and resists fading under heat or chemical exposure.

2. Thermal Transfer Printing

This method is perfect for creating long-lasting, high-contrast labels. Thermal transfer printers use heat to transfer durable ink from a ribbon onto specialized label material.

The result is a clear, long-lasting print that resists abrasion, moisture, and UV light. It’s commonly used for pre-cut or continuous label rolls applied to cables after printing.

3. Laser Marking

Laser wire printing delivers unmatched precision and permanence. Instead of using ink, it etches text directly onto the wire’s insulation surface.

This makes it resistant to smudging, solvents, and wear, which is ideal for aerospace, defense, and automotive applications where reliability is critical.

4. Hot Stamping

Though an older technique, hot stamping is still used for specific wire types. It uses heat and pressure to transfer pigment from a foil onto the wire surface. The result is a durable mark, though it’s slower and less flexible compared to modern methods like inkjet or laser.

Each method offers distinct advantages depending on your operational needs. Whether you prioritize speed, durability, or flexibility, choosing the right wire printing process ensures clear and lasting identification for every application.

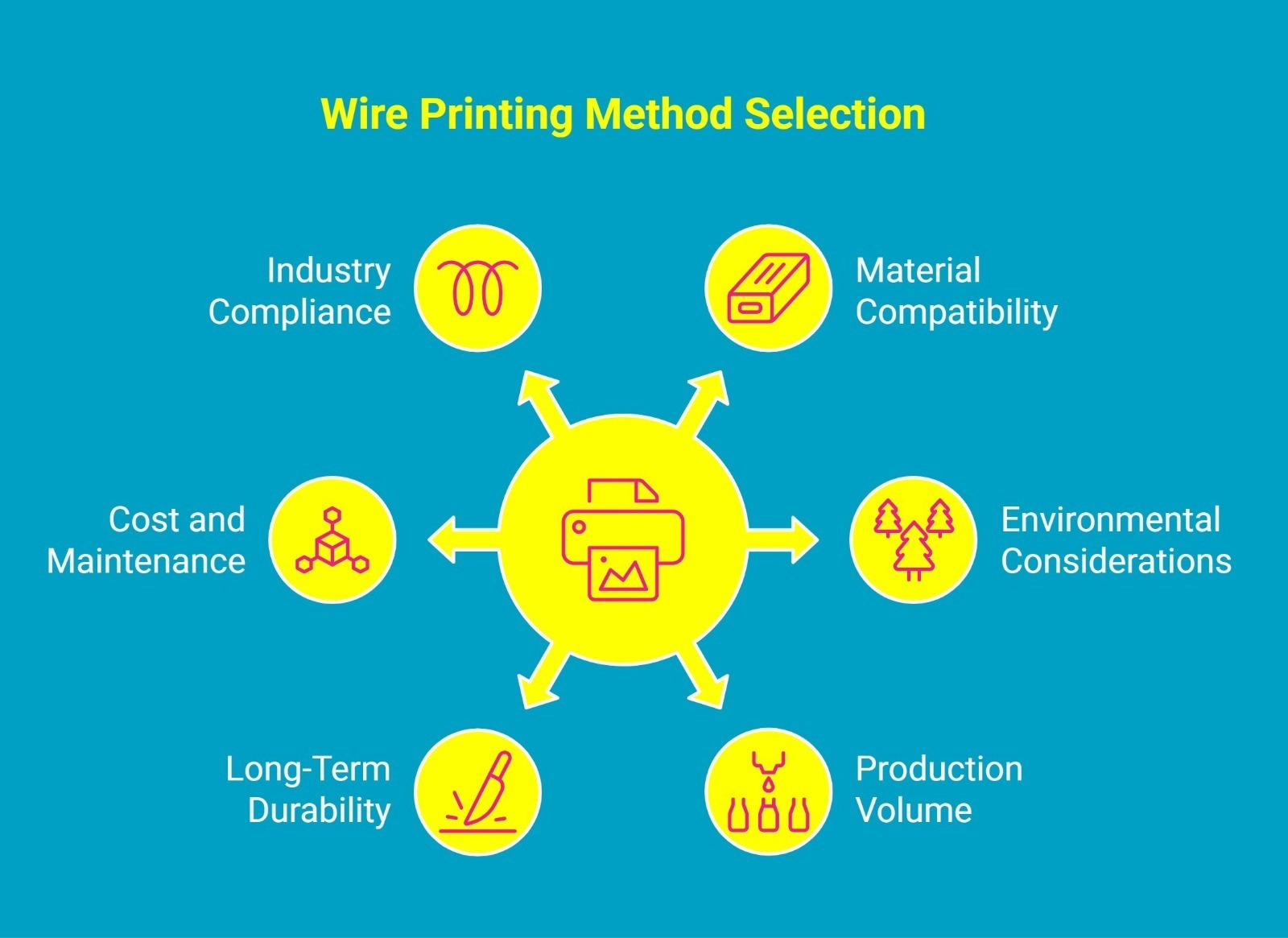

How Do You Choose the Right Wire Printing Method?

Picking the best wire printing method goes beyond budget or convenience. It’s about finding the perfect match for your materials, environment, and long-term reliability. The right choice ensures your markings stay clear, durable, and compliant no matter where they’re used. Here’s what to consider before making your decision:

1. Know Your Wire Material

Not all insulation types react the same way to printing. PVC, Teflon, and silicone wires each have unique surface properties. Inkjet printing may struggle on glossy coatings, while laser marking works best on matte or non-reflective surfaces. Always match the method to your wire’s insulation for maximum print adhesion and clarity.

2. Consider the Environment

Will your wires be exposed to heat, chemicals, or outdoor conditions? If so, durability becomes critical. Thermal transfer and laser marking hold up well in harsh environments, while inkjet works best in clean, indoor spaces.

3. Match Speed to Production Volume

For high-speed, continuous production lines, inkjet systems are hard to beat. They print directly on moving wires with minimal downtime. For smaller batches or custom labeling, thermal transfer printers offer precision and flexibility.

4. Prioritize Long-Term Durability

If you need labels that last for years, especially in aerospace or automotive applications, laser marking is the most reliable choice. For general use, thermal transfer provides durable and cost-effective results that hold up through everyday wear and tear.

5. Balance Cost and Maintenance

Each method has its trade-offs. Inkjet printers require ink refills and routine cleaning. Laser systems cost more upfront but need less maintenance. Thermal transfer printers strike a balance with dependable performance at a reasonable price.

6. Check Industry Compliance

In regulated industries like aviation, defense, or medical manufacturing, label quality is non-negotiable. Ensure your chosen method meets standards for legibility, permanence, and safety compliance.

Choosing the right wire printing method is about aligning technology with your goals. When you get it right, you’ll save time, reduce errors, and keep every connection clearly identified for years to come.

Which Are the Top 3 Wire Printers Worth Buying?

Choosing the right wire printer can make labeling faster, cleaner, and more reliable. The best ones deliver crisp, durable prints that hold up under any conditions.

If you want professional results without the hassle, here are three wire printers that truly stand out.

Epson LabelWorks LW-PX700 1" (24mm) Portable Label and Wire Marker Printer

The Epson LabelWorks LW-PX700 is a powerhouse for anyone who demands clear, professional, and durable labeling in fast-paced environments. From marking cables and tools to creating safety labels, this printer brings precision and efficiency right to your workspace or job site. Compact, portable, and built to last, it’s designed to keep up with the toughest labeling challenges.

Why You’ll Love the LW-PX700

- Versatile Labeling Power: Prints labels up to 1 inch (24mm) wide, perfect for everything from wires to safety signs.

- Instant Access Hotkeys: Dedicated buttons let you jump straight to common label formats without wasting time navigating menus.

- Add Your Own Style: Import and store up to five custom images such as company logos or warning symbols for professional branding.

- Less Waste, More Savings: Epson’s rollback technology cuts down tape margins to save material on every print.

- Effortless Batch Printing: The mixed-length feature prints multiple label sizes in one strip, separated neatly with the half-cut function.

- Rugged Yet Portable: Built for industrial and field work while staying light enough to carry anywhere.

- Guaranteed to Last: Protected by a lifetime warranty for total peace of mind.

The Epson LW-PX700 isn’t just a label maker; it’s a dependable partner for organized, efficient, and professional labeling in any environment.

2. Epson LabelWorks LW-PX400 Industrial Label Printer

The Epson LabelWorks LW-PX400 is the perfect mix of portability and performance for professionals who need reliable, on-the-go labeling. Designed for datacom installers, electricians, and field technicians, this compact printer brings flexibility to every workspace. With wireless connectivity and multi-material support, it handles everything from wire markers to heat shrink tubing with effortless precision.

Why the LW-PX400 Stands Out:

- Truly Wireless Printing: Print labels directly from your iOS or Android device using Bluetooth and Epson’s Label Editor Mobile App.

- Versatile Connectivity: Connect via Bluetooth or USB to your Windows PC, or use USB with Mac through Label Editor Lite Software for easy editing.

- Multi-Material Support: Works with heat shrink tubes, vinyl tape, magnetic tape, polyester tape, and even iron-on labels for complete versatility.

- Professional Labeling Tools: Create barcodes, QR codes, and templates using Epson’s free Label Editor Software for fully customized designs.

- Automatic Precision Cutting: Each label is neatly separated for clean, consistent results every time.

- Compact and Durable Build: Lightweight and protected by a rugged Drop-Guard Cover that absorbs impact during fieldwork.

- Lifetime Warranty: Backed by Epson’s trusted warranty, offering long-term value and peace of mind.

The Epson LW-PX400 combines mobility, durability, and wireless convenience, making it an essential tool for professionals who need high-quality labeling wherever the job takes them.

3. Epson LabelWorks LW-PX900 Industrial Label Printer

The Epson LabelWorks LW-PX900 is the ultimate choice for professionals who need fast, high-quality, and dependable wire printing. Designed for industrial environments, this powerhouse delivers 360 dpi high-resolution labels with unmatched clarity and durability.

Why the LW-PX900 Is a Game Changer:

- High-Speed Performance: Prints at impressive speeds while maintaining top-tier precision, ideal for large-scale labeling projects.

- Wide Label Range: Handles labels up to 1.5 inches (36mm) wide and is compatible with all LabelWorks PX tapes for maximum flexibility.

- Crisp Print Quality: Produces 360 dpi high-resolution output for professional-grade results on every print.

- Smart Efficiency Features: Auto-cut, auto-rewind, and mix-length printing save time and reduce tape waste.

- Pick-and-Print Convenience: Prevents label loss during batch printing, keeping your workflow seamless and organized.

- Intuitive Operation: Features a bright, backlit LCD screen and quick-access industrial hotkeys for effortless label creation.

- Rugged and Reliable: Engineered for industrial use, backed by a lifetime warranty for lasting confidence.

The Epson LW-PX900 takes wire printing to the next level, combining speed, precision, and durability in one powerful, professional-grade label maker.

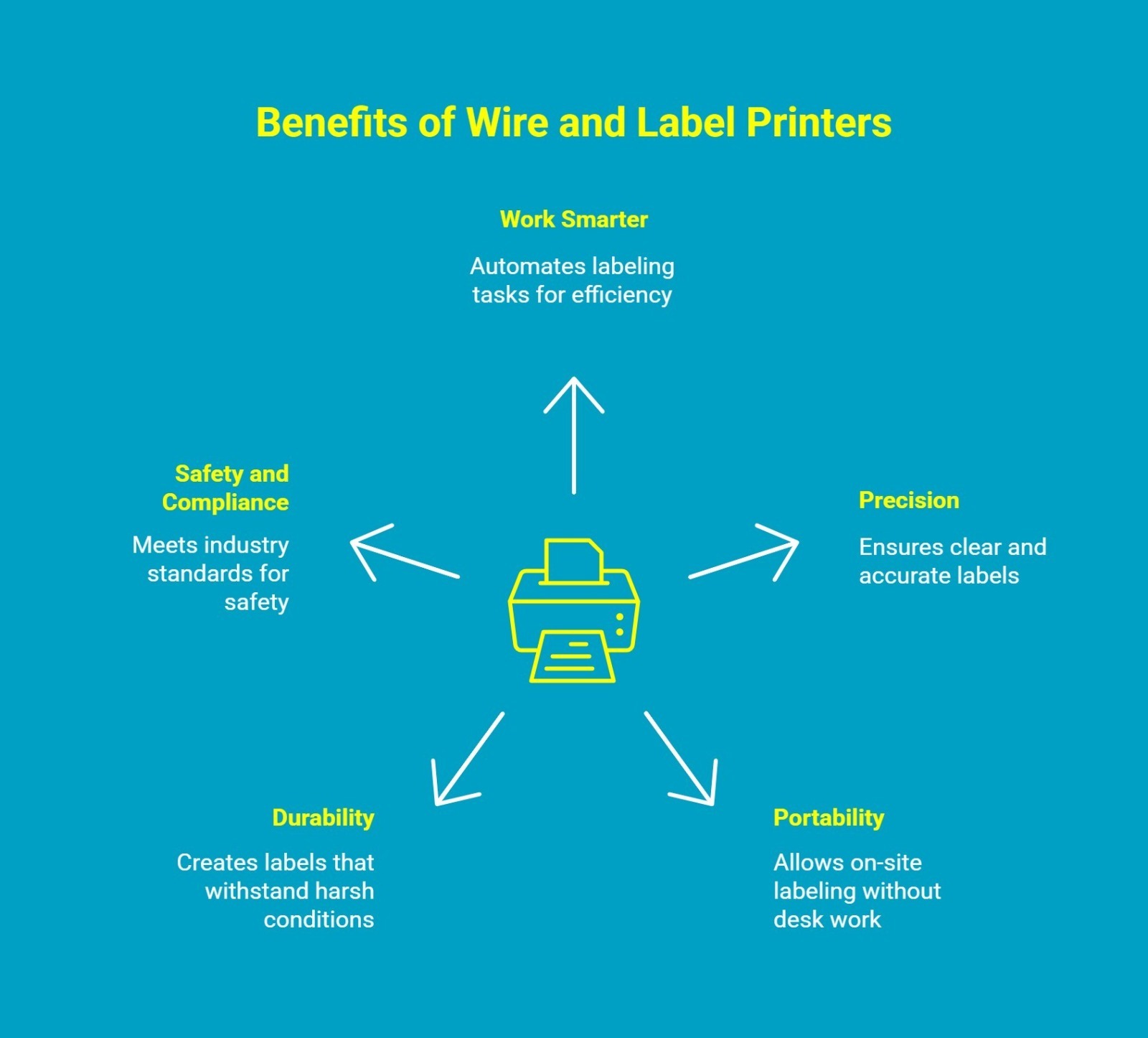

How Do Wire Printers and Label Printing Machines Help Simplify the Process?

Wire printers have completely changed how professionals organize and manage electrical systems. Instead of spending hours handwriting or manually tagging wires, you can now create crisp, durable labels in seconds.

These wire label printing machines simplify every step from design to application, saving time while improving accuracy and consistency.

Here’s how wire printers make the entire labeling process faster, smarter, and far more efficient for professionals in any industry.

1. Work Smarter, Not Harder

Automatic cutting, batch printing, and mix-length features make wire labeling quick and hassle-free. You can print multiple label sizes at once and avoid tedious manual trimming or alignment.

2. Precision That Speaks Volumes

High-resolution printing ensures every label, barcode, or symbol is perfectly sharp and easy to read. Clear labeling prevents costly errors and makes maintenance faster and safer.

3. Portable Power for On-the-Go Work

Modern wire printers are compact, wireless, and battery powered, so you can label directly on-site. Whether you’re in a workshop or on a job site, you can print exactly what you need without returning to your desk.

4. Built for Tough Conditions

Industrial grade printers use durable materials and advanced print technology to create labels that last. They resist heat, chemicals, and wear, making them ideal for demanding environments.

5. Safety and Compliance Made Simple

Consistent, legible labels ensure your projects meet safety standards and industry regulations. Technicians can trace connections faster, reducing risks and downtime.

Wire printers don’t just make labeling easier; they make it smarter. With the right machine, you get speed, precision, and durability all in one, helping you stay organized and efficient every step of the way.

When Should You Use Custom Printed Wire Labels?

There are times when basic labels just don’t cut it. If your project demands precision, durability, and a clean professional finish, custom printed wire labels are the way to go.

Here are the key situations where using them makes a real difference:

1. Big or Complex Installations

Working on control panels, server rooms, or large electrical systems? Custom printed labels make life easier. With every wire clearly marked in advance, you can trace connections in seconds and avoid costly mix-ups.

2. Tough Working Conditions

In environments where heat, chemicals, or outdoor exposure are a challenge, you need labels that last. Custom options use specialized materials and adhesives that stay put and stay readable even under pressure.

3. Meeting Safety and Compliance Standards

Some industries have strict labeling requirements, and handwritten tags just won’t do. Custom labels ensure your wiring meets safety codes, inspection standards, and regulatory compliance every time.

4. Adding a Professional Touch

Want your work to look as good as it performs? Custom labels can include your logo, color codes, or barcodes, giving your projects a polished, branded appearance that reflects professionalism and pride.

5. High-Volume or Repetitive Jobs

If you print the same labels over and over, why not simplify? Custom pre-printed labels come ready to apply, helping you save hours and stay consistent across multiple projects.

Custom printed wire labels aren’t just about organization; they’re about confidence. They help you work faster, stay compliant, and deliver a professional finish that lasts.

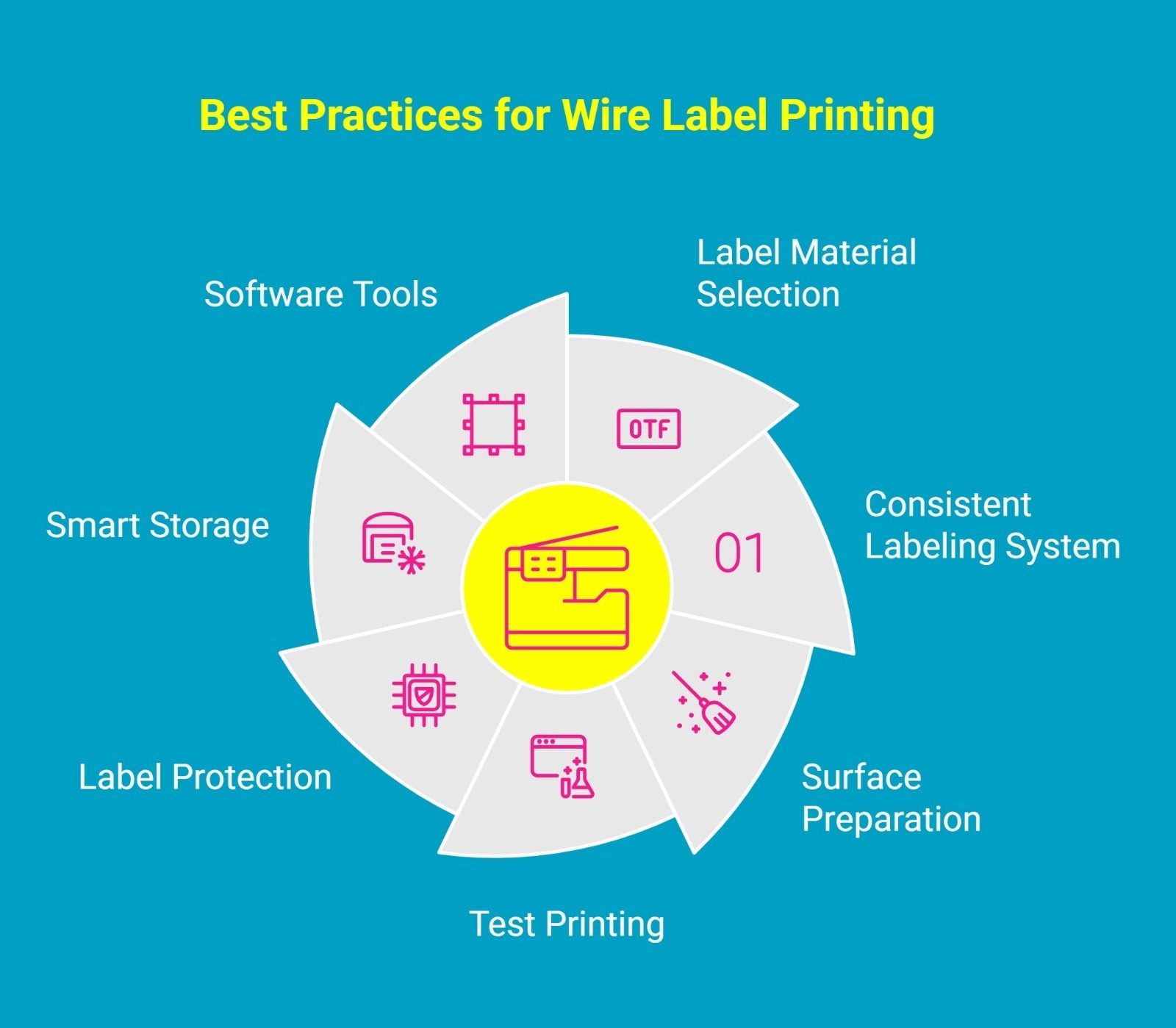

How Can You Get Perfect Results with Wire Label Printing?

Getting durable, professional wire labels is about more than just having a great printer. The real difference lies in how you plan, prepare, and print. A few simple but strategic steps can drastically improve the quality, readability, and lifespan of your labels while also saving time and reducing waste. Here are the best practices every professional should follow.

1. Pick the Perfect Label Material

Not all labels are built for the same job. Consider your environment before you start printing. Heat shrink tubing is best for high-temperature conditions where durability is critical.

Vinyl and polyester labels offer flexibility for general wiring tasks, while UV-resistant materials are essential for outdoor applications exposed to sunlight. Choosing the right label type ensures your markings stay legible and secure no matter the environment.

2. Keep a Consistent Labeling System

Establish a clear, uniform labeling format before printing. Decide on font size, color codes, and placement so your system remains consistent across projects.

This makes future troubleshooting and maintenance easier since every technician can instantly recognize what each wire represents. A standardized system also improves compliance with industry and safety regulations.

3. Prep Before You Print

Surface preparation makes a huge difference in how long labels last. Wipe each wire clean with a lint-free cloth before applying labels to remove dirt, oil, or moisture. Skipping this step often leads to poor adhesion and peeling labels over time, especially in high-traffic or high-heat environments.

4. Run a Test First

Before committing to a full batch, print a few sample labels. Check for readability, size accuracy, and alignment. This small step helps you catch formatting errors early, saving both materials and time.

It’s also an easy way to verify that your chosen font and print density are clear enough for your specific application.

5. Protect Your Work

Labels endure plenty of wear and tear, especially in industrial settings. To keep them intact, use laminated or self-laminating labels that protect printed text from abrasion, chemicals, and fading.

These added layers act like a shield, preserving your hard work even in the toughest conditions.

6. Store Smartly

Proper storage extends the life of your label materials and printing supplies. Keep label rolls, ribbons, and cartridges in a cool, dry space away from direct sunlight or extreme temperatures.

This prevents adhesive degradation and ensures consistent print quality every time you use them.

7. Use the Right Software Tools

Don’t underestimate the power of good software. Use your printer’s dedicated software or mobile app to design clear, compliant labels with barcodes, QR codes, and custom templates.

Make sure your settings are optimized for the material you’re printing on by adjusting print speed, temperature, and density for the best finish.

Following these best practices ensures your wire labels are durable, easy to read, and built to last. With the right approach, you’ll turn every labeling task into a smooth, efficient, and professional process.

Why DuraFast Is Canada’s Go-To Choice for Reliable Labeling Solutions?

Struggling with labels that fade, peel, or fail when you need them most? In fast-paced industrial environments, unreliable labeling can cause confusion, downtime, and costly mistakes.

That’s where we at DuraFast Label Company come in. We provide professional-grade wire printers and durable labeling solutions trusted by businesses across Canada to keep their operations organized, efficient, and compliant.

Why Professionals Trust Us for Labeling That Lasts:

- All-in-One Labeling Hub: We offer everything you need to get the job done right from wire and cable printers to heat shrink tubing and industrial label tapes. Our goal is to make labeling simple, seamless, and built to last.

- Backed by Trusted Brands: We partner with leading manufacturers like Epson, Brady, and Primera to deliver reliable, high-performance printers and supplies that meet the toughest industry standards.

- Custom Solutions for Unique Needs: Every business is different, so we provide custom label printing services designed around your exact specifications, whether you need wire wraps, color-coded labels, or branded materials.

- Fast Shipping and Local Expertise: With a Canada-based warehouse and a knowledgeable support team, we ensure quick delivery and personalized service every step of the way.

At DuraFast Label Company, we’re committed to helping you print smarter, faster, and stronger.

Ready to get started? Reach out to our team today!

Conclusion

Every connection tells a story, and a clearly printed label is proof of craftsmanship, not just compliance. Wire printing isn’t about keeping things neat; it’s about taking pride in precision. It shows attention to detail, respect for the work, and care for those who’ll maintain it long after the project is done.

Because in the end, the real difference between a job completed and a job mastered often comes down to something as small and as powerful as the label on a wire.

Frequently Asked Questions

What’s the best printer for wire labels?

The best printer depends on your needs. The Epson LabelWorks LW-PX400 and the Epson LabelWorks LW-PX700 are top choices for portability, durability, and high-quality printing in industrial applications.

Can I print directly on wires?

No, you can’t print directly on wires. Instead, use a wire label printer to print on heat-shrink tubes or self-laminating labels that are applied to the wire for lasting readability.

Are heat-shrink tubes better than adhesive wire labels?

Heat-shrink tubes are more durable and permanent, while adhesive labels are faster and easier to apply. Choose heat-shrink for long-term use and adhesive labels for flexible, quick applications.

How to print from phone through wire?

Connect your phone to the printer via USB or adapter, install the printer driver or app, select the document, choose the printer, and tap print to begin.

Do electrical wire label printers come with pre-made label templates?

Yes, most electrical wire label printers include built-in or downloadable templates for common wire and cable markings. These templates simplify setup and ensure consistent, compliant labeling across all your projects.

How do I use a label printer to mark electrical wires and cables safely?

Design your label using the printer’s software or app, print on heat-shrink tubes or self-laminating labels, and apply them to clean, unpowered wires. Always follow safety guidelines and use insulated tools when labeling.