A Deep Dive into Thermal Label Printing: Everything You Need to Know About Direct Thermal and Thermal Transfer

5th Aug 2025

Is your business struggling with smudged labels, fading text, or printer breakdowns in the middle of a busy day?

You're not alone. Label printing issues cost businesses time, money, and customer satisfaction. In a world where speed, accuracy, and durability are critical, choosing the right label printing method can make or break your workflow.

At DuraFast Label Company, we specialize in providing high-quality label printing solutions designed for serious professionals. Whether you run a warehouse, pharmacy, food production line, or retail operation, our selection of thermal label printers and consumables is built for demanding environments. We offer both direct thermal and thermal transfer printing systems, along with compatible Intermec and Toshiba TEC thermal ribbons, thermal POS receipt printers, and durable labels made to perform under pressure.

In this article, we break down everything you need to know about thermal label printing—specifically the two most common methods: direct thermal and thermal transfer. We'll cover how each technology works, when to use them, how they compare in terms of cost and performance, and how to choose the right solution for your needs.

How Thermal Label Printing Works

Thermal printing technology uses heat to produce images on labels or receipts, eliminating the need for traditional ink, toner, or ribbons (in some cases). It’s faster, cleaner, and generally more reliable for industrial and commercial use than conventional printing.

There are two main types:

- Direct Thermal Printing

- Thermal Transfer Printing

Each has its strengths, limitations, and ideal use cases. Let’s examine how these two methods differ.

Direct Thermal Printing: Simplicity Meets Speed

In fast-paced business environments, label printing needs to be efficient, cost-effective, and easy to manage. Direct thermal printing delivers on all three fronts—especially in operations that prioritize speed and short-term functionality over long-term durability.

What Is Direct Thermal Printing?

Direct thermal printing is a no-ink, no-toner method that relies entirely on heat-sensitive materials to produce images and text. The labels used are coated with a special thermochromic layer—a chemical compound that reacts when exposed to heat. When the printhead in a direct thermal printer applies heat to precise spots on the label, those spots darken, forming letters, barcodes, or graphics.

This process is frictionless and ultra-efficient. It doesn't require moving print mechanisms to apply ink or ribbon layers. Instead, it's the label itself that changes color, eliminating several consumables and moving parts from the process.

How It Works: The Mechanics Behind the Magic

Key components and steps in direct thermal printing:

Heat-Sensitive Media:

Only direct thermal paper or labels can be used. These materials are specially coated to react to heat.

Thermal Printhead:

The printer's thermal printhead contains microscopic heating elements arranged in a line. Each element corresponds to a tiny dot in the print area.

Contact and Heat Activation:

As the media passes under the printhead, specific elements heat up. When they come into contact with the thermally sensitive layer, the coating reacts, turning black in the shape of your text or barcode.

Print Control:

The process is controlled by your software or printer driver, which sends instructions on what needs to be printed and where. Print speed and density can often be adjusted, depending on the requirements.

There’s no ribbon, ink cartridge, or toner involved, which makes the process simpler, cleaner, and faster than many other printing technologies.

Advantages of Direct Thermal Printing

1. Lower Operational Costs

Since there's no ribbon, ink, or toner involved, you're cutting out a major chunk of consumable expenses. You only need to purchase direct thermal labels—nothing more.

2. Minimal Maintenance

Fewer moving parts and consumables mean there's less that can go wrong. No ribbons to jam, fewer cleaning cycles, and less mechanical wear and tear. It’s ideal for businesses that don’t have time or resources for frequent maintenance.

3. Quiet and Fast

Thermal printing is generally much quieter than dot-matrix or impact printers and significantly faster than inkjets. That’s particularly useful in customer-facing environments where noise reduction is important (like at a POS counter).

4. Smaller Footprint

Because they require fewer internal components, direct thermal printers tend to be more compact and portable. This makes them ideal for kiosks, mobile printing setups, and constrained workspaces.

5. Eco-Friendly Simplicity

No need for ribbons or toner cartridges means fewer materials are manufactured, shipped, and disposed of. This makes direct thermal printing more environmentally friendly, especially for businesses aiming to minimize waste.

Limitations of Direct Thermal Printing

1. Susceptible to Environmental Conditions

Direct thermal labels are vulnerable to heat, light, humidity, abrasion, and chemicals. Over time, exposure to these elements can cause the print to fade or darken unnecessarily. This makes them unsuitable for archival or industrial use.

2. Limited Lifespan

Most direct thermal labels are readable for up to 6–12 months, depending on storage and usage conditions. This is fine for shipping or temporary tagging but problematic for anything long-term.

3. Monochrome Only

Direct thermal printing can only produce images in black (or very limited grayscale). If your labels require brand-specific colors, visual warnings (like GHS labels), or product packaging appeal, this isn’t the right technology.

4. Surface Sensitivity

Rough handling or contact with oils and cleaners can damage the print. Even fingernail scratches can leave marks on the label surface if pressure is applied.

5. Printhead Wear

Although maintenance is low, using low-quality or non-topcoated labels can cause buildup or abrasion on the printhead, shortening its lifespan. While printheads in these printers are fairly durable, they can be expensive to replace.

Best Use Cases for Direct Thermal Printing

Direct thermal technology shines in high-volume, short-term labeling applications where speed and simplicity outweigh longevity.

Shipping Labels:

Ideal for logistics and ecommerce businesses (UPS, FedEx, USPS), where labels are used for just a few days.

Retail Receipts:

Most point-of-sale (POS) systems use direct thermal receipt printers due to their fast output and minimal maintenance.

Food Packaging:

Fresh food items often require labels that are applied and consumed quickly, such as deli tags, meat wrappers, or bakery labels.

Inventory & Shelf Tags:

Especially in retail or warehouse environments where items turn over rapidly and frequent label changes are needed.

Event or Transit Tickets:

Tickets that are valid for short periods (like bus or event passes) benefit from the speed and low cost of direct thermal output.

Label Options for Direct Thermal Printing

Your choice of label material significantly impacts print quality, resistance, and application suitability.

1. Non-Topcoated Direct Thermal Labels

Use Case: Basic, budget-friendly labeling for short-term indoor use

Pros: Most affordable option; works well for shipping and logistics

Cons: Highly sensitive to light, heat, and abrasion; fades quickly

2. Premium Topcoated Direct Thermal Labels

Use Case: Labels exposed to moderate handling or environmental stress

Pros: Topcoat adds a protective layer that increases resistance to moisture, abrasion, and light

Cons: Slightly higher cost, but significantly longer shelf-life and readability

Pro Tip: If you’re experiencing fading, smudging, or premature print failure, consider upgrading to topcoated labels. They're especially useful in humid or variable-temperature environments.

Should You Choose Direct Thermal Printing?

Direct thermal printing is ideal if:

- Your labels are used temporarily (under 12 months)

- You're in a high-volume, low-costlabeling environment

- You want low-maintenanceprinting with minimal setup

- You don’t need color or long-term durability

Avoid it if:

- Your labels are stored in hot, bright, or wet environments

- You need high-resolution brandingor color-coded labels

- You’re labeling items for multi-year tracking or regulatory compliance

Thermal Transfer Printing: Longevity and Durability

When durability is non-negotiable, thermal transfer printing rises to the challenge. Whether you're labeling products for the outdoors, archiving inventory for years, or tagging chemical containers, this technology ensures your labels won’t fade, smudge, or break down under pressure. Unlike direct thermal printing, which relies on heat-sensitive paper, thermal transfer printing uses ribbons and robust materials to create long-lasting, highly resistant labels.

What Is Thermal Transfer Printing?

Thermal transfer printing is a heat-based printing process that uses a ribbon made of wax, resin, or a wax-resin combination. When the printhead applies heat, it melts the ribbon's ink, transferring it onto the surface of the label or tag.

This process is known for producing exceptionally durable, high-contrast images and text that can withstand tough environments, including extreme temperatures, chemicals, UV light, moisture, and abrasion.

Unlike direct thermal printing, which is more suited to short-term use, thermal transfer printing creates labels that last for years, making it ideal for long-term tracking, compliance labeling, and rugged industrial use.

How It Works: The Science Behind the System

Here’s a breakdown of how thermal transfer printing works:

Thermal Transfer Printer

The printer contains a thermal printhead that heats up specific elements based on your image or barcode design.

Thermal Transfer Ribbon

The ribbon sits between the printhead and the label. It's coated with wax, resin, or a hybrid of both. When heated, the ink melts and adheres to the label surface.

Media Material

Unlike direct thermal, this system supports a wide range of media, including coated paper, polypropylene, polyester, and vinyl. This versatility is key to creating labels that resist environmental damage.

Heat Application

The printhead heats specific dots on the ribbon, which transfers ink to the label in the desired pattern. The result is a permanent, smudge-proof image.

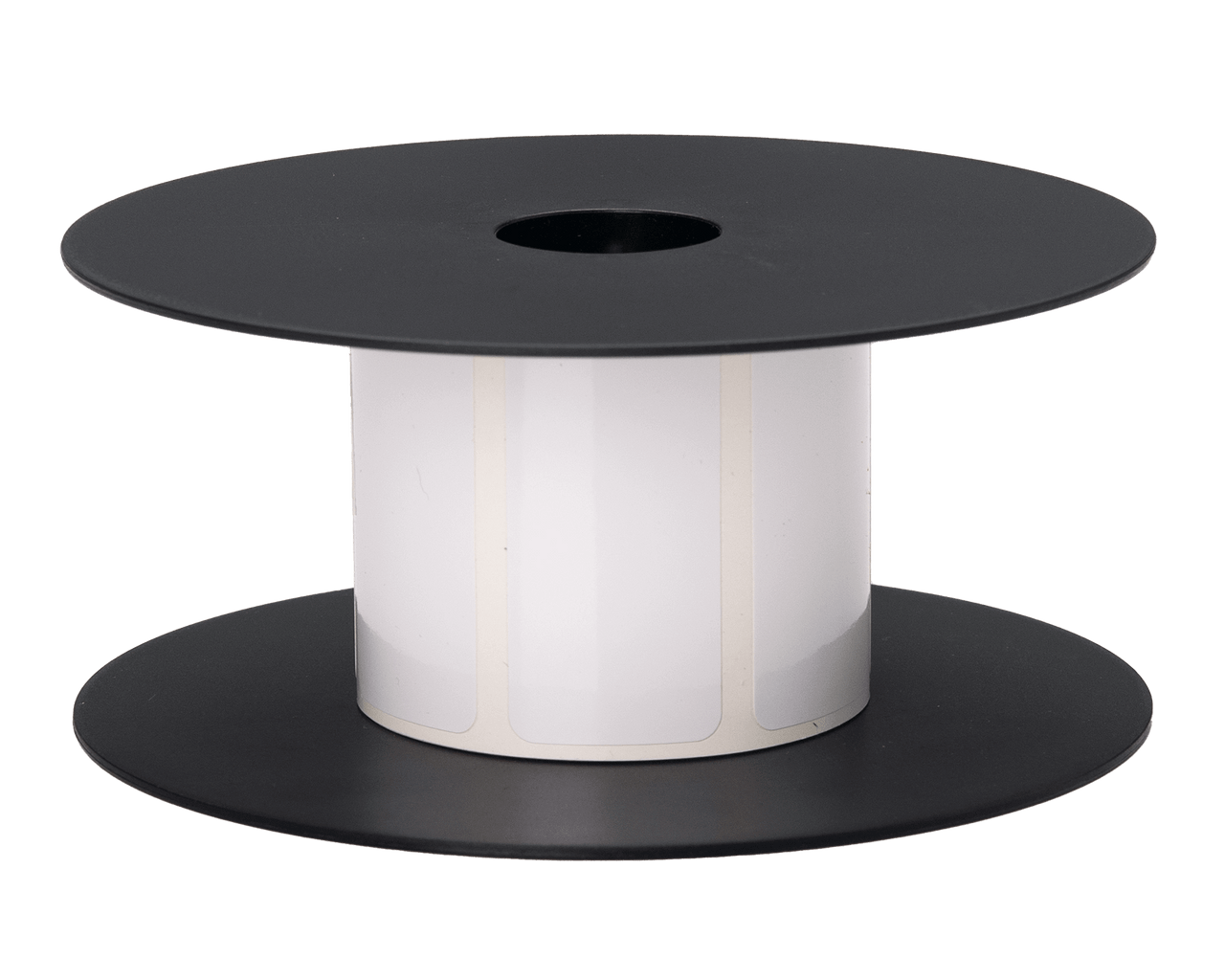

Ribbon Winding

After ink transfer, the used ribbon winds onto a take-up spool, keeping the printing process clean and consistent.

Advantages of Thermal Transfer Printing

1. High Durability Across Environments

Thermal transfer labels can withstand extreme heat, cold, humidity, chemicals, abrasion, and UV exposure. This makes them ideal for outdoor use, lab samples, manufacturing processes, and regulatory compliance.

2. Compatible with Numerous Substrates

Whether you're labeling flexible packaging, metal drums, circuit boards, or cryogenic vials, thermal transfer printing works with a wide variety of label materials, including:

- Coated and uncoated paper

- Polypropylene

- Polyester (Mylar)

- Polyimide

- Vinyl

3. Crisp, Long-Lasting Print Quality

Prints are smudge-proof and fade-resistant. This is crucial for barcodes that must be scannable years down the line or safety labels that need to remain legible in industrial settings.

4. Color Printing Options

Although it doesn’t offer full CMYK process color like inkjet printers, thermal transfer printing supports spot color by using ribbons in red, blue, green, white, or metallic shades. These are helpful for color-coded inventory systems, branding, and safety labels.

5. Better for Long-Term Archiving

Many industries, such as pharmaceuticals or asset management, require documentation and tracking over long periods. Thermal transfer printing ensures labels remain legible and compliant for the entire life of the product or record.

6. Consistent Performance

The ribbon acts as a buffer between the printhead and label, reducing wear on the printhead and extending its lifespan. Compared to direct thermal, printheads in thermal transfer printers often last longer, especially when paired with quality ribbons.

Limitations of Thermal Transfer Printing

1. Requires Ribbons

You’ll need to purchase and manage ribbons along with your label stock. These can be made of wax, resin, or a wax-resin hybrid, each suited for different environments. Ribbons add an extra consumable cost and require proper storage.

2. Higher Initial Investment and Maintenance

Thermal transfer printers typically have more moving parts than direct thermal models, leading to:

- Slightly more complex setup

- Ribbon loading and alignment

Occasional maintenance to clean and align the ribbon path

3. Slower Print Speed (in Some Cases)

Depending on your ribbon and media type, thermal transfer printing may be slower than direct thermal printing—especially when switching colors or using specialty materials.

4. Waste Management

Spent ribbons result in additional waste and disposal needs, though some suppliers offer eco-friendly or recyclable ribbon cores.

Best Use Cases for Thermal Transfer Printing

Thermal transfer printing excels in harsh, demanding environments where reliability and legibility matter for compliance, traceability, or safety.

Industrial Barcoding:

Durable barcodes for steel, lumber, electronics, and heavy equipment

1. Laboratory & Pharmaceutical Labels:

Vials, slides, and specimen containers that undergo freezing, thawing, or chemical exposure

2. Long-Term Asset Tracking:

Labeling IT equipment, tools, or inventory that needs to be tracked for years

3. Outdoor and Weatherproof Labels:

Gardening supplies, construction tags, and products stored outside

4. Healthcare and Compliance Labels:

Labels that must comply with FDA, GHS, or OSHA regulations

5. Warranty or Serial Number Tags:

For electronics, machinery, or appliances that require long-term tracking

6. Document Archiving:

Library systems, legal records, or patient files that need clear, scannable labels for decades

Label Options for Thermal Transfer Printing

Your choice of label material determines how your labels perform under specific conditions:

1. Paper Thermal Transfer Labels

Use Case: General purpose labeling (e.g., retail tags, shipping, inventory)

Pros: Affordable and widely available

Cons: Less durable; not ideal for moisture or chemical exposure

2. Polypropylene Thermal Transfer Labels

Use Case: Warehouse, retail, or product labeling with moderate exposure

Pros: Tear-resistant, moisture-resistant, flexible

Cons: Not ideal for high-temperature applications

3. Polyester and Synthetic Labels

Use Case: Harsh environments, compliance labeling, outdoor use

Pros: Extremely durable; resistant to chemicals, UV, abrasion, and extreme temps

Cons: Higher cost; requires resin ribbons for best results

4. Custom Thermal Transfer Labels

Use Case: Branding, product packaging, or special adhesives

Options: Custom die-cuts, colors, pre-printed logos, high-tack or removable adhesives

Pro Tip: Pair your label material with the right type of ribbon:

Wax ribbons – Ideal for coated paper in low-abrasion environments

Resin ribbons – Required for synthetics and high-durability needs

Wax-Resin ribbons – Balanced choice for coated paper and light synthetic use

Should You Choose Thermal Transfer Printing?

Choose thermal transfer printing if:

- You need labels that last more than a year

- Your application involves harsh or changing environments

- You require regulatory compliance (e.g., GHS, FDA, UL)

- You're using synthetic or specialty materials

- Your labels must stay legible and scannable over time

Avoid it if:

- You're printing short-term labels with low exposure

- You're managing tight budgets and want to avoid ribbon costs

- You’re printing monochrome shipping labels in bulk (direct thermal may be more efficient)

Comparing the Two: Direct Thermal vs. Thermal Transfer

|

Feature |

Direct Thermal |

Thermal Transfer |

|

Consumables |

Labels only |

Labels + Ribbons |

|

Durability |

Moderate |

High |

|

Image Lifespan |

Short-term |

Long-term |

|

Print Speed |

Fast |

Slightly slower |

|

Environmental Resistance |

Low |

High |

|

Cost per Label |

Lower |

Higher |

|

Maintenance |

Lower |

Higher |

|

Color Options |

Monochrome |

Available |

Key Takeaway: Use direct thermal printing for fast, short-term labeling. Use thermal transfer printing when durability and resistance are essential.

Cost Implications: Upfront vs. Long-Term Investment

Choosing between direct thermal and thermal transfer isn't just about print quality—it's also about cost-effectiveness. Here's how the costs compare:

Direct Thermal:

- Lower hardware cost

- No need for ribbons

- Less maintenance required

- Cheaper for high-volume, short-life applications

Thermal Transfer:

- Higher hardware and supply costs

- Requires compatible thermal ribbons (e.g., Intermec or Toshiba TEC)

- More robust output reduces need for reprinting

Hidden Costs to Consider:

- Label fade can result in re-labeling or customer service issues

- Worn-out printheads from low-quality paper can increase replacement costs

For businesses needing long-term labeling, thermal transfer often offers better value over time.

Label Materials: What Works Best?

For Direct Thermal:

- Paper-based labels

- Non-topcoated for short-term

- Topcoated for more protection

For Thermal Transfer:

- Paper (standard)

- Polyester (high durability)

- Polypropylene (chemical resistance)

Label selection directly affects print quality, durability, and total cost.

Matching Labels to Your Thermal Label Printers

Whether you're using desktop or industrial thermal barcode printers, pairing them with the right labels is essential. Here’s how to match:

Direct Thermal Printers:

- Use direct thermal labelsonly

- Ensure labels match printer width and DPI

Thermal Transfer Printers:

- Use ribbons compatible with your device

- Select appropriate label material (paper vs. film)

- Check for ribbon and label size compatibility

Common brands like Intermec and Toshiba TEC offer thermal ribbons engineered to pair with their specific printers, improving print clarity and lifespan.

Choosing the Right Thermal Ribbon

Ribbons come in three main types:

- Wax: For uncoated and matte paper labels; least durable but economical

- Wax/Resin: More durable; used for semi-gloss paper and some synthetics

- Resin: Maximum durability; best for high-resistance synthetic labels

- Recommended Brands:

- Intermec thermal ribbons: Known for consistent quality and print longevity

- Toshiba TEC thermal ribbons: Designed for high-resolution industrial printing

Thermal POS Receipt Printers: Where Direct Thermal Shines

Thermal POS receipt printers use direct thermal printing because:

- Speed is critical

- Labels and receipts are not stored long-term

- Low maintenance

- These printers are widely used in:

- Retail checkouts

- Hospitality (restaurants, hotels)

- Ticketing and transportation

They’re cost-effective, compact, and offer high-speed performance.

Thermal Barcode Printers: A Cross-Industry Staple

Thermal barcode printers are indispensable across multiple sectors:

- Healthcare: Patient IDs, specimen tracking

- Logistics: Shipment tracking, warehouse inventory

- Manufacturing: Product identification, compliance labeling

- Retail: Price tags, shelf labels

Thermal barcode printing is essential for accuracy and compliance in supply chains.

Key Questions to Ask Before You Choose

- How long does your label need to last?

- Will it be exposed to sunlight, heat, or chemicals?

- Do you need color printing or is black and white sufficient?

- What’s your average print volume?

- What kind of surface will you apply the label to?

Answering these helps identify whether a direct thermal or thermal transfer system fits best.

Custom Thermal Transfer Labels for Branding and Compliance

Need branded labels, specialty adhesives, or labels pre-printed with variable data? Custom thermal transfer labels can meet both marketing and regulatory demands.

Applications include:

- Chemical labeling (GHS compliance)

- Asset tracking with logos

- Unique barcodes for serialized products

- Durable outdoor branding

Work with suppliers who can deliver custom cuts, adhesives, and high-quality finishes.

Are You Ready to Upgrade Your Printing System?

Still trying to decide which thermal label printer setup is right for your operation? Whether you’re printing shelf tags, patient IDs, industrial barcodes, or food labels, choosing between direct thermal and thermal transfer printing could redefine how efficient and reliable your process becomes.

At DuraFast Label Company, we offer one of the most comprehensive selections of commercial and industrial-grade label printing solutions in the industry. Our catalog includes thermal transfer printers, thermal barcode printers, and thermal POS receipt printers from leading manufacturers. We also supply premium topcoated direct thermal labels, non-topcoated options, and custom thermal transfer labels that meet specific regulatory and performance standards. Plus, we carry genuine Intermec and Toshiba TEC thermal ribbons to keep your output crisp and dependable.

Need help selecting the right system for your workflow? Contact us today to speak with a specialist, or place your order online and streamline your operations with one of the best selections of thermal label printers available anywhere.