How To Select the Right Label Material for a Product?

21st May 2025

Choosing the right label material isn’t just about aesthetics; it’s about performance, durability, and compliance. Labels play an essential role in product branding, regulatory adherence, and functionality. Whether you're labeling a bottle of wine, a jar of salsa, or an industrial container, selecting the correct label material ensures that your product not only looks professional but withstands the environment it encounters.

Let’s explore popular label material types and provide guidance on how to match them with specific applications so your products make a lasting impression on the shelf and in the consumer's hands.

1. Understanding Label Material Basics

Label materials are made from a face stock (the visible part of the label), an adhesive layer, and a liner (which is peeled off during application). Each component must be considered when selecting a label.

Key factors:

- Durability:Will the label be exposed to water, sunlight, chemicals, or abrasion?

- Application surface:Smooth, rough, curved, or flat?

- Environmental conditions:Indoor, outdoor, refrigeration, or freezing temperatures?

- Adhesion needs:Permanent, removable, or repositionable?

Matching label material properties to your product’s environment ensures longevity and clarity.

2. Paper Labels: Cost-Effective and Versatile

Paper is one of the most widely used label materials due to its affordability and print versatility.

Pros:

- Budget-friendly

- Excellent print quality

- Compatible with both inkjet and laser printers

- Easy to apply and remove (depending on adhesive)

Cons:

- Not moisture-resistant

- Less durable for long-term or rugged applications

Best for:

- Dry goods

- Packaging inserts

- Mailing labels

- Product labeling for indoor use

Types:

- Matte paper (non-glossy, writable)

- Glossy paper (shiny, photo-quality)

- Kraft paper (rustic, eco-friendly aesthetic)

3. Polyester Labels: Rugged and Long-Lasting

Polyester (PET) labels are designed for durability in harsh environments. These synthetic labels withstand extreme temperatures, moisture, chemicals, and abrasions.

Pros:

- Waterproof and weatherproof

- Tear-resistant

- High tensile strength

- Excellent for industrial use

Cons:

- Higher cost than paper

- Typically not writable without special pens

Best for:

- Outdoor products

- Electronics and appliance labeling

- Industrial equipment

- Safety and warning labels

Finish options:

- Silver matte (commonly used for asset tags)

- White gloss or matte

- Clear polyester for transparent effects

4. Vinyl Labels: Flexible and Weatherproof

Vinyl labels offer excellent flexibility and adhesion, making them ideal for curved surfaces and outdoor use. Their durability and resistance to elements make them a strong choice for challenging applications.

Pros:

- Water-resistant

- UV-resistant

- Conforms to curves and irregular surfaces

Cons:

- Typically requires professional-grade printers

- More expensive than paper labels

Best for:

- Outdoor signage

- Bumper stickers

- Chemical containers

- Custom thermal transfer product labels

Vinyl labels are particularly well-suited for applications requiring both longevity and flexibility.

5. Polypropylene Labels: Economical and Durable

Polypropylene (BOPP) is a synthetic film that offers good durability and moisture resistance at a lower price point than polyester or vinyl.

Pros:

- Moisture-resistant

- Cost-effective synthetic option

- Resistant to oil and chemicals

Cons:

- Not as rugged as polyester

- Less flexible than vinyl

Best for:

- Food and beverage containers

- Health and beauty products

- Household cleaners

- Jar and bottle labels

Available in white, clear, and silver finishes, BOPP labels are a versatile choice for many industries.

6. Specialty Materials: Unique Needs Require Unique Labels

Some products demand materials with advanced or aesthetic features.

Examples include:

- Tamper-evident materials:Break or void when removed (ideal for pharmaceuticals and security packaging).

- Freezer-grade materials:Withstand freezing temperatures without peeling.

- Recycled or eco-friendly materials:Appeal to environmentally conscious consumers.

- Static cling labels:Used for temporary applications like car window decals.

Best for:

- Pharmaceuticals

- Sustainable brands

- Promotional labels

- Refrigerated or frozen goods

Selecting specialty materials often requires testing and consultation to ensure proper performance.

7. Environmental Exposure Considerations

Environmental conditions directly impact label material performance. Always assess:

- Temperature extremes:Freezer-grade or heat-resistant labels may be necessary.

- Moisture and humidity:Waterproof synthetics like BOPP or vinyl excel here.

- UV exposure:Outdoor products need UV-resistant materials.

- Chemical contact:Choose chemical-resistant films like polyester.

By evaluating the product lifecycle, you can anticipate conditions that may cause labels to degrade or fail.

8. Label Adhesive Options

Even the best label material can fail without the proper adhesive. Adhesives are formulated based on material compatibility, application temperature, and required permanence.

Types of adhesives:

- Permanent:Bonds securely and resists removal (standard for most product labels)

- Removable:Peels off cleanly without residue (ideal for temporary use)

- Freezer-grade:Maintains adhesion in low temperatures

- Aggressive:High-tack adhesive for hard-to-stick surfaces

Pro Tip: Test your label material and adhesive combo before committing to large batches.

9. Print Technology Compatibility

Different label materials are optimized for different print methods.

Inkjet-compatible materials:

- Glossy or matte paper

- Inkjet labelcoated with BOPP or polyester

Thermal transfer-compatible materials:

- Polyester and vinyl (requires ribbon)

- Synthetic materials with high heat tolerance

Direct thermal-compatible materials:

- Premium-coated direct thermalpaper for short-term use (e.g., shipping labels)

Choosing the wrong material can result in smudging, poor adhesion, or print fading. Match material to your printer type for best results.

10. Regulatory and Industry Standards

Certain industries have strict labeling requirements.

Examples:

- Food & Beverage:FDA-compliant materials for direct and indirect food contact

- Healthcare:Durable, legible labels with tamper-evident features

- Chemical:GHS labeling standards for hazardous materials

Review relevant regulations to ensure your label materials meet safety, compliance, and performance expectations.

11. BS5609-Certified GHS Labels for Hazardous Goods

If your product is shipped by sea and contains hazardous materials, you must comply with the Globally Harmonized System (GHS) for chemical labeling. In this context, choosing a BS5609-certified label material is essential for meeting international maritime safety standards.

What is BS5609?

BS5609 (British Standard 5609) is a certification for pressure-sensitive labels used on chemical drums and containers shipped by sea. To be certified, labels must pass rigorous durability tests, including saltwater immersion, abrasion, and UV exposure.

Why It Matters:

- Ensures labels remain legible and affixed during harsh marine conditions.

- Meets global regulatory standards for shipping hazardous goods.

- Helps avoid fines, shipment delays, and safety violations.

Best Materials for BS5609-Certified Labels:

- Polyester (PET): Excellent durability and chemical resistance.

- Polyethylene (PE): Flexible, durable, and water-resistant.

- Pair with high-quality thermal transfer ribbons for optimal adhesion and print durability.

12. Label Aesthetics and Branding Impact

Material choice affects more than durability — it shapes brand perception.

- Matte finishes create a natural or artisanal look

- Glossy finishes offer a sleek, professional appearance

- Clear materials create a "no-label" look for premium appeal

- Textured or metallic materials add visual interest

13. Testing and Prototyping

Before mass production, always test label performance:

- Apply to actual packaging under real conditions

- Assess for peeling, smudging, or fading

- Confirm legibility after exposure to light, moisture, or chemicals

Request samples from your supplier and conduct print and application tests to avoid costly errors.

14. Cost vs. Performance Trade-Offs

High-performance materials may cost more upfront but reduce long-term risks and reprinting costs.

Tips for cost-effective labeling:

- Use paper for low-risk, indoor applications

- Opt for BOPP over polyester when extreme durability isn't required

- Bulk ordering can reduce per-label costs

Balance your budget with your product's real-world needs for the best ROI.

15. Application Methods and Machinery

Your labeling process also affects material selection. Will you apply labels by hand or machine?

Manual application considerations:

- Flexible materials like vinyl are easier to apply by hand

- Avoid stiff labels that bubble on curved surfaces. Purchase high-quality color label printers onlineto address this issue.

Automated application:

- Ensure liner material is compatible with labeling machines

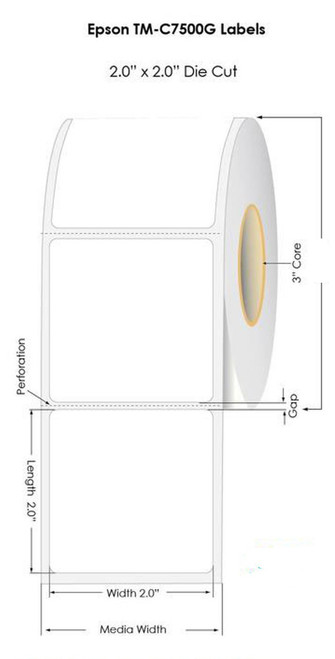

- Die-cut shapes should align precisely with machine specs

Consult your printer or applicator manufacturer to verify material compatibility.

Partner with DuraFast Label Company for Your Labeling Success

Selecting the right label material is a critical part of your product's success — from branding to compliance and durability. At DuraFast Label Company, we offer a wide variety of premium label materials, from cost-effective paper to high-performance synthetics like polyester, vinyl, and BOPP. Whether you need waterproof labels, custom thermal transfer labels, or eco-friendly options, our experts are here to guide you.

We also provide industry-leading high-quality color label printers, laser sheet labels for sale, and technical support to ensure you get the most out of every label you print. Trust us for quality, consistency, and service that elevates your product presentation.

Contact us today and let us help you find the perfect label material for your needs today.