The Evolution of Label Printing: From Traditional Methods to AI-Driven Smart Labels

7th Jul 2025

What’s on a label today might be smarter than you think.

Think back to when a product label was little more than a printed sticker slapped on a box. It told you the brand, the product name, and maybe some directions or ingredients. But now? That same label can track inventory, update itself in real time, and communicate directly with your smartphone.

The labeling industry has undergone a seismic transformation—from manually typeset prints to advanced, AI-driven smart labeling systems. And with consumers demanding more information, businesses chasing efficiency, and regulations tightening, this shift isn’t just exciting—it’s essential.

At DuraFast Label Company, we’ve been working right at the center of this change. Whether it's supporting small businesses with high-quality color label printers or helping industrial clients set up custom thermal transfer labels for compliance and logistics—we’ve seen what’s working, and we know what’s next.

In this article, we’ll walk through how label printing has evolved—from its traditional beginnings to the rise of digital and on-demand systems, the growing use of RFID and smart labels, and how artificial intelligence and automation are reshaping the way labels are created, printed, and managed.

A Brief Look Back: Traditional Label Printing and Its Limitations

Before the digital age, label printing was a labor-intensive process. Early labels were printed using letterpress—a relief printing technique where the image or text is raised above the surface. As time passed, offset printing, flexography, and gravure printing became standard.

Traditional Label Printing Methods:

-

Letterpress Printing: Used raised metal plates and was ideal for simple, small-batch labels.

-

Flexographic Printing: Used flexible plates and quick-drying inks, suitable for large volumes.

-

Offset Lithography: Offered higher image quality but involved costly setup and longer turnaround.

-

Gravure Printing: Best for extremely high-volume jobs due to long plate life and high image consistency.

While these methods served their era, they had significant constraints:

-

Long lead times

-

Expensive setup for short runs

-

Limited flexibility for variable data

-

Waste-heavy processes

-

Manual intervention at almost every step

This meant that businesses requiring frequent updates or custom labeling were often at a disadvantage—cost-wise and time-wise.

The Digital Turn: How On-Demand and Color Printing Changed Everything

When digital label printing hit the market in the late 20th century, it was more than just an upgrade in print technology—it was a radical shift that redefined how businesses of all sizes approach product labeling.

Before this, companies had to rely on analog methods that demanded long lead times and large minimum orders. This meant forecasting demand months in advance and storing thousands of pre-printed labels—many of which would become obsolete due to a product update, regulation change, or design refresh.

What Changed with Digital Label Printing?

Here’s a closer look at the major benefits that made digital printing a game-changer:

1. Shorter Print Runs Became Cost-Effective

Traditionally, printing a small batch of labels was prohibitively expensive due to setup costs like printing plates, dies, and ink calibration. Digital printers removed the need for all that. You could now print 50 labels just as easily and economically as 5,000.

For startups, craft brands, or seasonal products, this was a breakthrough. They could finally access professional-quality labels without bloated inventories or high upfront costs.

2. Customization Became Easier

Digital printing enabled variable data printing—the ability to change text, images, barcodes, or colors from one label to the next without stopping the print job.

This opened the door to:

-

Serial number tracking

-

Personalized packaging (e.g., "Share a Coke with…")

-

Localized branding for different markets

-

Private labeling for multiple resellers

3. Faster Turnaround Times

Need to launch a new flavor next week? Or respond to a sudden regulatory change? Digital printing slashed turnaround times from weeks to hours. With on-demand printing, businesses could design, approve, and print labels in-house or with a local partner almost instantly.

4. Full-Color Label Printing Became Accessible

Digital color printing eliminated the need for separate color plates. CMYK inkjet and laser technologies enabled rich, photo-quality graphics without extra setup costs.

That meant businesses didn’t have to compromise on branding. You could have professional-looking, eye-catching labels on every bottle, bag, or box—regardless of your company size.

The Shift in Printer Choices: Meeting Different Business Needs

As digital printing matured, businesses diversified their equipment to match specific applications. Let’s take a deeper look at the three main categories:

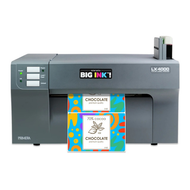

A. High-Quality Color Label Printers

These are the go-to for companies that need full-color branding on their labels—such as in:

-

Food & beverage

-

Health & beauty

-

Retail and boutique packaging

Printers like the Afinia L801, Epson ColorWorks C6500, or Primera LX500 deliver photo-quality images and vibrant colors, often on gloss, matte, or specialty substrates. Many of these printers also support waterproof and chemical-resistant inks, making them ideal for products exposed to moisture or abrasion.

Use Case Example: A coffee roaster prints custom, full-color labels for 10 seasonal blends each month. Instead of outsourcing to a print shop and waiting two weeks, they can print exactly the number of labels needed for each roast, updating the flavor notes, roast date, or QR code in real time.

B. Thermal Label Printers

These black-and-white workhorses are essential for logistics, barcoding, and warehouse environments.

-

Direct Thermal Printers: Use heat-sensitive paper; no ribbons needed. Best for short-life applications like shipping labels.

-

Thermal Transfer Printers: Use a ribbon to transfer ink onto the label. This results in labels that can withstand sunlight, chemicals, abrasion, and temperature extremes.

Use Case Example: A medical lab uses thermal transfer labels to ensure test sample information remains legible throughout transport and storage, even under refrigeration.

C. Hybrid and Variable Data Printers

Some printers combine both color and thermal capabilities or allow seamless switching between designs and data fields.

Use Case Example: A winery uses a hybrid system to print full-color branding while embedding a unique serial code and bottling date on each label for tracking and authenticity.

Thermal Transfer and Laser Sheet Labels in the Digital Era

As digital printing made in-house production viable, businesses adopted different label materials and formats to fit their workflow. Two of the most popular formats emerged: thermal transfer labels and laser sheet labels.

Thermal Transfer Labels

Why they matter:

These labels offer superior durability, especially for environments where the label will face friction, chemicals, moisture, or UV light.

How it works:

A printer uses a thermal printhead and ribbon to transfer wax, resin, or a wax-resin mix onto the label surface.

Best for:

-

Barcoding

-

Shipping and logistics

-

Warehouse bin labels

-

Medical and laboratory labeling

-

Outdoor storage

Label Material Options:

-

Polyester

-

Polypropylene

-

Vinyl

-

Paper (with protective coatings)

Advantages:

-

Crisp, smudge-resistant text

-

Long-term readability

-

Excellent resistance to harsh conditions

-

Laser Sheet Labels

Why they matter:

Laser sheet labels are a cost-effective option for businesses that already own a standard office laser printer. They allow you to print multiple labels per page—perfect for small runs, test batches, or internal use.

Best for:

-

Office labeling

-

Mail merge applications

-

Product samples

-

Packaging slips or inserts

Advantages:

-

No specialized printer required

-

Easy to store and use

-

Available in dozens of layouts and sizes

The Business Impact: What This Digital Shift Enabled

The widespread adoption of on-demand digital label printing changed the game for many businesses. Here are three specific benefits worth underscoring:

1. Faster Go-to-Market

Brands no longer had to wait weeks for custom labels to arrive. They could launch products almost instantly—especially valuable in fast-moving industries like beauty, supplements, and food & beverage.

2. Improved Inventory Management

Instead of warehousing thousands of pre-printed labels, companies could print only what they needed. This:

-

Reduced waste

-

Freed up storage space

-

Allowed for quick updates to designs or data

3. Lower Barrier to Entry for Innovation

Want to A/B test two label designs? Try a seasonal variation? Offer limited-edition SKUs?

Digital printing gave businesses the freedom to experiment without committing to massive label orders.

RFID, QR Codes, and the Rise of Smart Labels

Digital printing solved many problems—but the industry wasn’t done evolving. As supply chains globalized and product tracking became critical, labels started getting smarter.

What Are Smart Labels?

Smart labels include any type of label that stores or transmits data. This might be via:

-

QR codes readable by mobile devices

-

Temperature-sensitive materials that change color with conditions

These aren’t passive pieces of paper anymore. Smart labels now act as mini communication hubs.

Where Are Smart Labels Used?

-

Retail: Track inventory, fight theft, improve checkout speed

-

Pharmaceuticals: Monitor temperature and expiration

-

Food & Beverage: Improve traceability and transparency

-

Logistics: Enable real-time tracking and condition monitoring

For businesses, the benefits are substantial:

-

Reduced errors in inventory and logistics

-

Better compliance with regulatory tracking requirements

-

Enhanced customer engagement through scannable content

Imagine a wine label that not only tells you the year and vineyard, but also shows pairing suggestions when scanned with a phone. Or a pharma label that alerts you if the product was exposed to unsafe temperatures.

Smart labeling has made that a reality—and it’s only getting more intelligent.

Artificial Intelligence: The Next Shift in Label Printing

As labeling systems become more integrated with digital supply chains, artificial intelligence is taking center stage.

How AI Is Reshaping Label Printing

Predictive Analytics

AI systems can now predict print volume needs, reducing waste and ensuring just-in-time production. Businesses no longer need to overstock labels “just in case.”

Automated Quality Control

Through machine vision, AI can detect misprints, alignment issues, and color inconsistencies in real time—reducing manual QA efforts and returns.

Dynamic Label Design

AI tools can automatically generate label variations based on data inputs like language, regulatory standards, region, or SKU. This is particularly useful for companies operating across multiple markets.

Real-Time Personalization

For direct-to-consumer brands, AI makes it possible to personalize labels at the individual level—think names, colors, even personalized messages on packaging.

AI-Powered Compliance Updates

Labeling regulations often change across regions or industries. AI-enabled systems can flag outdated content and recommend updates instantly, keeping businesses compliant without manual research.

Automation: Printing Meets Smart Manufacturing

As the labeling industry evolves, automation is playing an increasingly central role in transforming production floors into smart manufacturing environments. While artificial intelligence is revolutionizing decision-making, real-world automation is handling the physical tasks that used to require teams of operators and hours of manual labor.

Together, AI and automation are not just speeding up the process—they're making it more reliable, scalable, and cost-effective.

What Does Label Printing Automation Actually Mean?

Label printing automation refers to a combination of hardware and software technologies working in sync to eliminate manual intervention throughout the labeling process. It connects different systems—design tools, printers, packaging lines, and inventory platforms—to create a seamless, fully integrated labeling workflow.

Here's a closer look at how this works in practice:

Key Components of Label Printing Automation

1. Print Scheduling Integration with ERP and Inventory Systems

Modern businesses operate with Enterprise Resource Planning (ERP) systems to track inventory, manage orders, and forecast demand. By integrating label printing into these systems, companies can automatically generate labels based on real-time inventory data or production needs.

For example:

When a new batch is scheduled in the ERP system, labels can be auto-generated with the correct product name, expiration date, and batch number.

Shipping labels can be printed on-demand the moment a packing slip is created.

Benefits:

-

Eliminates manual label generation

-

Ensures consistency between what’s printed and what’s packed

-

Reduces errors due to mislabeling or outdated information

2. Robotic Label Applicators on Production Lines

Label application used to be one of the most labor-intensive aspects of packaging. Now, robotic applicators—paired with high-speed thermal label printers—can apply hundreds of labels per minute with pinpoint accuracy.

These machines can handle:

-

Front/back labeling

-

Wrap-around labeling for bottles and jars

-

Corner labeling for boxes

-

Tamper-evident seals

They're also capable of adjusting in real time for variations in package size or alignment, further reducing waste.

Benefits:

-

Consistent, accurate application

-

Reduced labor costs

-

Scalable operations for high-volume production

3. Automated Material Handling for Blank Stock and Finished Rolls

Efficiency doesn’t stop at the printer. Automated feeders and rewinders are being used to load blank label rolls and unload printed ones without interrupting the print process.

Automated label roll management helps:

-

Prevent production delays due to manual roll changes

-

Maintain alignment and tension for better print quality

-

Reduce waste from misfeeds or roll damage

Advanced systems can even detect low material levels and alert operators—or automatically switch to a new roll mid-run.

4. Software That Synchronizes Label Design with Packaging Runs

Perhaps one of the most important parts of labeling automation is label design synchronization. This involves software platforms that ensure the label artwork, barcodes, compliance information, and other data are always accurate and up-to-date for every packaging run.

Examples include:

-

Automatically updating nutrition facts on food labels based on the latest formulation

-

Updating serial numbers, lot numbers, or expiration dates from a central database

-

Managing multiple product SKUs from a single design template

This becomes especially powerful when paired with high-quality color label printers or systems producing custom thermal transfer labels, where visual clarity and accuracy are non-negotiable.

The Synergy of AI and Automation: Why Integration Matters

Automation doesn’t operate in isolation. The real value emerges when it works in tandem with artificial intelligence.

AI algorithms can:

-

Predict print volumes based on sales trends

-

Schedule label runs during off-peak hours to save energy

-

Adjust print quality based on material type or environmental conditions

-

Flag inconsistencies in data before they reach the printer

Together with automation, this intelligent labeling workflow can:

-

Minimize human error

-

Accelerate production cycles

-

Support traceability and compliance

-

Optimize resource use across the board

Why High-Quality Thermal Label Printers Are Central to Automation

Thermal printing—particularly thermal transfer—is well-suited for automation because of its reliability, speed, and durability. Many of the best thermal label printers now offer full support for industrial automation protocols, enabling direct connection to PLCs (Programmable Logic Controllers), MES (Manufacturing Execution Systems), and ERP platforms.

These printers:

-

Can be mounted directly onto robotic applicators

-

Accept variable data inputs from databases in real time

-

Offer remote monitoring and diagnostics to reduce downtime

When producing custom thermal transfer labels, this matters greatly—especially in industries like food, pharmaceuticals, manufacturing, and logistics, where both compliance and speed are essential.

Real-World Impact of Labeling Automation

Let’s consider what this looks like in actual operations:

Logistics & Fulfillment

A warehouse receives an order. The ERP system generates a pick list. Simultaneously, it sends instructions to the printer to create a shipping label with customer data, a barcode, and tracking information. A robotic arm picks the box, applies the label, and sends it to the loading dock—without human intervention.

Manufacturing

A bottling line fills and seals bottles of hand sanitizer. Sensors detect each bottle, and a robotic applicator places a label printed just seconds earlier by a connected thermal transfer printer. The label includes product data, an expiration date, and a regulatory symbol. All synchronized automatically through a MES interface.

Food Production

A bakery updates its ingredients. The system pushes the change to a central label design file. At the next production run, the new ingredient list prints automatically on every label—with the correct batch number, date, and allergen notice. A robotic applicator applies the updated labels seamlessly.

Benefits Across the Board

Label printing automation delivers tangible business results:

-

Accuracy: Reduces mislabeling, which can lead to recalls or compliance penalties.

-

Speed: Accelerates throughput without sacrificing quality.

-

Efficiency: Minimizes waste and labor costs.

-

Scalability: Easily handles increased demand or new product lines.

Most importantly, automation frees up your staff to focus on value-added tasks—like quality control, innovation, or customer engagement—instead of label prep and manual data entry.

Sustainability and the Demand for Eco-Friendly Labels

Consumers are demanding sustainable packaging, and labels are part of that equation.

Green Labeling Strategies:

-

Recyclable label materials

-

Biodegradable adhesives

-

Eco-friendly thermal ribbons

-

On-demand printing to reduce waste

-

Laser sheet labels optimized for reduced toner use

Smart and AI-enabled systems can now optimize label dimensions, placement, and even materials based on carbon footprint reduction targets. Even thermal label printers are being designed with lower energy requirements and recyclable components.

The Regulatory Factor: Staying Compliant in a Changing World

As smart labels and AI become more common, regulations around labeling are growing more complex.

Industries like food, pharmaceuticals, and chemicals must meet strict guidelines around:

-

Ingredient listing

-

Country of origin

-

Hazard warnings

-

Tamper evidence

-

Temperature tracking

Smart systems now assist in maintaining compliance through:

-

Automated audits of label content

-

Real-time updates based on regulation changes

-

Version control to ensure outdated labels aren’t reused

That’s especially important for businesses handling high volumes or frequent product changes.

Is Your Label Printing Strategy Ready for the Future?

Ask yourself this: are your labels doing enough?

Are they just identifiers—or are they working tools that drive efficiency, compliance, and customer engagement?

If you’re still relying on outdated methods or disconnected systems, it’s time to reassess.

At DuraFast Label Company, we help businesses prepare for what’s next in labeling. Whether you're upgrading to high-quality thermal label printers, sourcing custom thermal transfer labels for specific workflows, or needing precision with your color label printers—we offer one of the most comprehensive selections of industrial and commercial printing solutions in North America.

With our range of laser sheet labels and thermal transfer options, you can create durable, professional labels without outsourcing. And with on-demand printers that scale from desktop units to production-grade machines, there’s a fit for every size of business.

Order now from DuraFast Label Company and see how the right printing tools can help your business meet rising demands, stay compliant, and increase operational efficiency. From high-quality color label printers to durable thermal label printers—we have the tools that meet your needs now and into the future.