Thermal Transfer vs Direct Thermal Printing: What’s the Difference?

5th Sep 2025

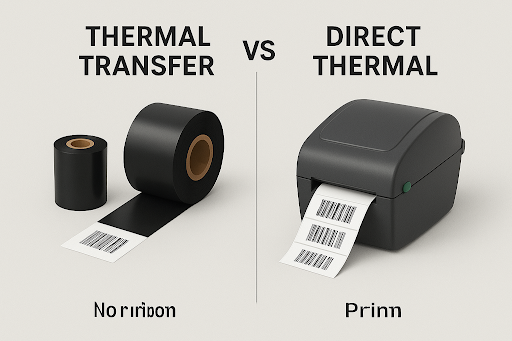

If you’ve ever searched for the right method, you’ve probably come across the debate of thermal transfer vs direct thermal printing. They might look like the same technology, but they’re actually quite different. Many businesses struggle to decide which printing method is best for their labels, barcodes, or shipping needs. Both printing technologies have specific benefits, and choosing the right one can save you time, money, and frustration.

Did you know that the way your labels are printed can affect how long they last, how easy they are to scan, and how professional they look? Think of it like comparing two tools in a toolbox. Each one is useful, but they work best in different situations.

In this guide, we’ll keep things simple and help you understand the basics of direct thermal vs ribbon printing so you can make the right choice for your business.

What is Direct Thermal Printing?

Direct thermal printing uses heat-sensitive paper to create an image directly on the label. There’s no ink, toner, or ribbon involved. The printhead applies heat, and the paper reacts to produce your text or barcode.

Pros of Direct Thermal Printing:

- No ribbons or cartridges to buy, making it cost-effective.

- Easy to operate and maintain.

- Perfect for short-term labels like UPS/Fedex shipping labels or receipts.

Cons of Direct Thermal Printing:

- Labels can fade over time, especially with heat, light, or friction.

- Not ideal for long-term product labels or outdoor use.

Direct thermal printers are popular in retail, logistics, and healthcare, where labels are used for a shorter period and don’t need to last for years.

What is Thermal Transfer Printing?

Thermal transfer printing uses a thermal transfer printer ribbon that gets heated by the printhead and transfers ink directly onto the label. This process creates sharp, durable, and long-lasting prints, making it ideal for barcodes, shipping labels, and product tags where clarity and resistance to fading are important.

Pros of Thermal Transfer Printing:

- Produces labels that resist heat, moisture, and chemicals.

- Works on a wide range of materials like paper, polyester, and polypropylene.

- Great for product labeling, asset tagging, and barcodes that need to last.

Cons of Thermal Transfer Printing:

- Requires ribbons, which add to the ongoing cost.

- Slightly more complex than direct thermal printing.

If you want labels that last for years, especially in tough environments, thermal transfer printing is the better choice.

How to Decide Between Direct Thermal and Thermal Transfer

When comparing thermal transfer vs direct thermal, think about how long you need your labels to last and where they’ll be used.

- If you need shipping labels that only need to survive a few days, direct thermal is perfect.

- If you need product labels that will be exposed to heat, chemicals, or rough handling, thermal transfer is the safer bet.

Everyday Examples to Make It Clear

- Direct Thermal Example: Printing a shipping label for a package that will be delivered within 3–5 days.

- Thermal Transfer Example: Printing a chemical drum label that must remain readable for years in outdoor conditions.

- Thermal Transfer Example number 2: barcode that needs to be scanable for many years

By matching the right printing method with the right application, you’ll save money and avoid reprints.

Ribbons and Printers: What You Need to Know

Once you choose thermal transfer printing, you’ll also need to select the right ribbon. A thermal transfer ribbon comes in different types, like wax, wax-resin, or resin, each designed for specific durability levels.

For example, if you’re using a thermal label printer, Zebra, you’ll find compatible ribbons that ensure your printer delivers high-quality, long-lasting labels.

Conclusion

Both printing methods have their place, and the right choice depends on your label’s purpose. Direct thermal is perfect for short-term needs, while thermal transfer ensures long-lasting durability. Choosing wisely will save you money, prevent wasted labels, and keep your business running smoothly.

At DuraFast Label Company, we make it easy to find the right printers, ribbons, and supplies to fit your labeling needs. Explore our wide range of printers, ribbons, and labels today and start creating professional-quality prints that last.

FAQs

- Which is cheaper: direct thermal or thermal transfer printing?

Direct thermal is generally cheaper upfront since you don’t need ribbons. However, thermal transfer can be more cost-effective in the long run if you need durable labels that don’t require reprints.

- Do thermal transfer ribbons work with all printers?

No. Ribbons must match the specifications of your printer. For example, a Zebra thermal printer ribbon is designed specifically for Zebra models.

- How long do direct thermal labels last?

Typically, they last 6 to 12 months before fading, depending on storage conditions.

- Can I use thermal transfer printing for outdoor labels?

Yes. Thermal transfer is the best choice for outdoor or industrial applications where labels need to withstand harsh conditions.

- Is it hard to switch from direct thermal to thermal transfer printing?

Not at all. Most printers can handle both methods, but you’ll need to add a thermal transfer printer ribbon to switch.

- Do thermal printers need ink or toner?

No. Neither direct thermal nor thermal transfer printers use ink or toner. Direct thermal uses heat-sensitive paper, while thermal transfer uses ribbons.

- What’s the best printer for shipping labels?

The Godex DT4x, aA direct thermal printer is usually best shipping label printer since the labels only need to last until delivery. The Godex DT4x can print standard 4x6 shipping labels used by UPS, Fedex and all the other leading shipping companies.

- Can I print in color with thermal transfer?

Yes. Thermal transfer can produce labels in different colors by using colored ribbons, unlike direct thermal, which is limited to black prints.