Why Terminal Block Labeling Standards Are Important?

12th Feb 2026

Key Highlights

-

Terminal block labeling improves electrical safety and reduces wiring errors.

-

International standards guide how terminals, wires, and circuits are identified.

-

Durable, readable labels are critical in industrial environments.

-

Consistent labeling speeds maintenance, inspections, and troubleshooting.

-

The right labeling tools simplify compliance and long-term reliability.

Terminal blocks sit at the heart of electrical panels, control cabinets, and machinery, yet they are often one of the most poorly labeled components. Unclear or missing terminal identifiers can lead to wiring mistakes, delayed troubleshooting, and costly downtime during maintenance or inspections.

Terminal block labeling standards make connections easy to understand. Clear labels help technicians work safely, find the right terminals quickly, and avoid mistakes that could damage equipment or cause safety risks.

In this guide, we explain what terminal block labeling means, why standards matter, which regulations apply, what information labels must include, common mistakes to avoid, and how the right tools can help you maintain compliant, professional electrical systems.

What Does Terminal Block Labeling Mean?

Terminal block labeling refers to the practice of clearly identifying terminals, connection points, and associated wiring using standardized markers, tags, or labels. These identifiers help technicians understand circuit flow, polarity, and function without guesswork.

Proper labeling ensures each terminal can be traced accurately across schematics, panels, and equipment, supporting safe installation, maintenance, and troubleshooting throughout the system’s lifecycle.

Why Is It Essential to Follow Terminal Block Labeling Standards?

Terminal block labeling standards are essential for maintaining safe, accurate, and reliable electrical systems. Without consistent labeling, installations become difficult to understand, risky to maintain, and prone to errors. Following standards ensures clarity, supports compliance, and keeps electrical assemblies functional and serviceable over their entire lifespan.

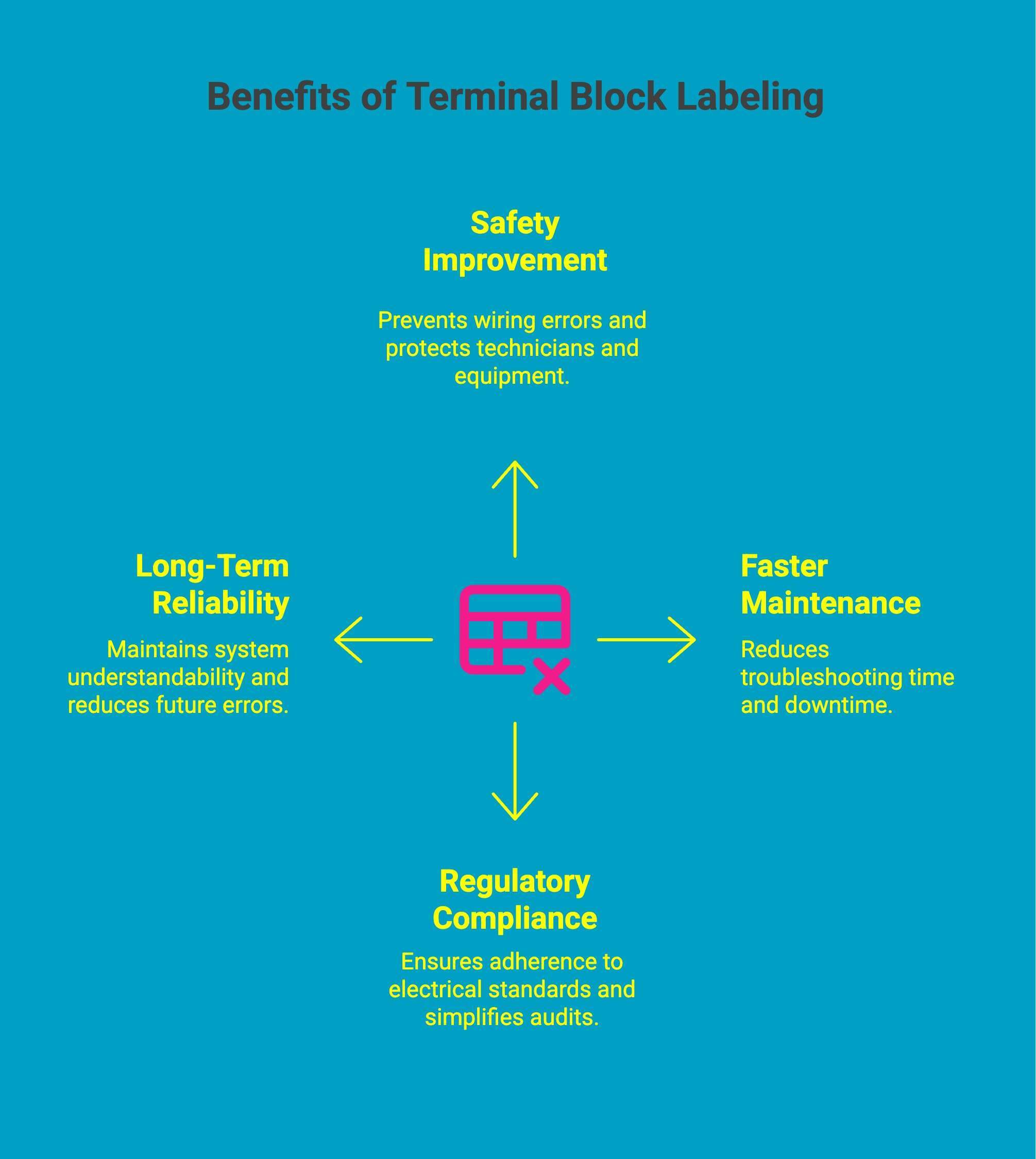

The importance of these standards is reflected in the following key areas:

1. Safety Improvement and Error Prevention

Clear, standardized terminal block labeling helps prevent wiring errors, accidental cross-connections, and polarity mistakes. By making circuit functions immediately understandable, labeling reduces the risk of unsafe interactions with energized components during installation, troubleshooting, or repair, protecting both technicians and equipment.

2. Faster Maintenance and Diagnostics

Well-labeled terminals allow technicians to trace circuits quickly and confidently. This reduces troubleshooting time, minimizes downtime, and enables faster fault isolation, especially in complex panels where unclear or missing labels can significantly delay maintenance work.

3. Regulatory Compliance and Audit Readiness

Standardized labeling demonstrates adherence to recognized electrical practices during inspections and audits. Proper labeling supports documentation accuracy, simplifies verification processes, and reduces the likelihood of compliance issues arising from unclear or inconsistent electrical identification.

4. Long-Term Reliability in Electrical Assemblies

Consistent labeling ensures systems remain understandable long after installation. Future technicians can safely service or modify equipment without relying on institutional knowledge, improving long-term reliability and reducing the risk of errors as systems evolve.

Ultimately, following terminal block labeling standards protects people, preserves system integrity, and supports sustainable electrical operations.

Want to learn how professionals mark electrical wires clearly and safely? Read this practical guide on best practices, tools, and methods for accurate electrical wire marking.

What Labeling Standards Must Every Terminal Block Follow?

Terminal block labeling is governed by a combination of international, regional, and industry-specific standards. These standards define how terminals should be identified, formatted, and maintained to ensure clarity, consistency, and safe operation across different electrical environments and applications.

The most commonly followed standards include:

1. IEC Standards for Terminal Block Identification

IEC standards establish conventions for terminal numbering, conductor identification, and functional markings. These guidelines are widely used in control panels and industrial equipment to ensure consistent identification that aligns with schematics and wiring diagrams.

2. UL and CSA Requirements for Labeling

UL and CSA standards focus on safety, durability, and traceability within certified electrical assemblies. They ensure terminal block labeling supports safe operation, withstands environmental stress, and remains compliant in regulated installations.

3. ANSI and NFPA Guidelines for Industrial Marking

ANSI and NFPA guidelines address the clarity and effectiveness of industrial labeling. They emphasize proper warning communication, consistent formatting, and visibility across control systems to reduce confusion and enhance workplace safety.

4. ISO Standards Related to Wire and Component Labeling

ISO standards promote uniform labeling practices across international projects. They are especially relevant for complex machinery and global installations where consistent identification supports maintenance and cross-border compliance.

5. Industry-Specific Regulations for Terminal Block Marking

Certain industries, including manufacturing, energy, and automation, apply additional labeling rules based on operational risk. These regulations tailor identification requirements to specific safety, performance, and inspection needs.

6. Manufacturer-Recommended Labeling Practices

Manufacturers often provide recommended labeling formats designed to fit their terminal blocks and accessories. Following these practices improves fit, readability, and compatibility while supporting standardized installation methods.

Together, these standards ensure terminal block labeling remains clear, reliable, and compliant across diverse electrical systems.

Looking to improve accuracy and efficiency in wire printing? This step-by-step wire printing guide explains materials, printers, and techniques used in real-world electrical and industrial applications.

What Information Must Be Included on Terminal Block Labels?

Terminal block labels must clearly communicate essential details so connections can be identified accurately and handled safely. Providing complete and consistent information reduces confusion, supports maintenance, and prevents wiring errors during installation, inspection, or future system modifications.

Terminal block labels should include the following information:

-

Identification numbers or circuit codes: These identifiers link each terminal directly to schematics and wiring diagrams, helping technicians trace circuits quickly, reduce troubleshooting time, and avoid mistakes during installation, inspection, maintenance, or future system modifications.

-

Voltage and current ratings: Clearly stating electrical limits helps technicians confirm that terminals operate within safe ranges, preventing overloads, overheating, or component failure that could damage equipment or create serious safety risks.

-

Polarity or phase indicators: Polarity and phase markings prevent reversed connections and cross-wiring, which can cause malfunction, short circuits, or damage to sensitive components, especially in AC systems and control panels.

-

Wire size or gauge compatibility: Indicating compatible wire sizes ensures conductors fit securely, maintain proper contact, and meet electrical codes, reducing the risk of loose connections, excessive heat, or premature failure.

-

Terminal function or purpose: Describing each terminal’s role clarifies how the connection is used within the system, making installation, testing, and maintenance easier for technicians unfamiliar with the panel layout.

-

Safety symbols or compliance marks: Required symbols and certification marks show compliance with standards and regulations, signaling safe usage conditions and helping panels pass inspections without delays or costly rework.

-

Manufacturer details or part numbers: Including manufacturer names or part numbers improves traceability, simplifies sourcing replacements, and ensures compatible components are used when repairs, upgrades, or expansions are needed.

-

Environmental or durability indicators: These indicators show whether labels can withstand heat, moisture, chemicals, or vibration, ensuring information remains legible and reliable in harsh industrial or outdoor environments.

Including the right information ensures clarity, reduces miswiring, and improves long-term system reliability.

What Are the Requirements for Label Durability and Readability?

Terminal block labels must remain clear and readable for the entire lifespan of the electrical system, even in demanding industrial environments. Using the right materials, print quality, and tools, such as a dedicated terminal block label maker, ensures every terminal block and label continues to communicate accurate information reliably.

Key durability and readability requirements include:

1. Material and Environmental Resistance

Labels must withstand heat, vibration, oils, chemicals, and humidity without fading or peeling. High-quality terminal block label printing ensures markings remain intact, preventing misidentification in control panels and industrial enclosures.

2. Text Size, Contrast, and Visibility

Text should be large enough to read at a glance, with strong contrast against the label background. Clear formatting reduces errors during installation, inspection, and troubleshooting in dense terminal layouts.

3. Permanent and Removable Label Options

Some systems require permanent labels, while others need removable or replaceable markers during modifications. Choosing the right labeling method allows flexibility without sacrificing clarity or compliance.

Durability and readability ensure labels remain functional safety tools, not decorative markings.

How Should You Properly Label Terminal Blocks for Compliance?

Proper labeling is as much about placement and consistency as it is about content.

-

Follow IEC and UL standards for terminal identification: Applying recognized standards ensures labels are consistent, compliant, and easy to understand across installations, helping technicians interpret terminals correctly and reducing errors during inspection, maintenance, or future system upgrades.

-

Use durable, heat-resistant labels suited to the environment: Selecting materials designed for heat, moisture, chemicals, or vibration ensures labels remain legible over time, preventing loss of critical information in demanding electrical or industrial operating conditions.

-

Apply clear numbering or alphanumeric sequences: Logical, sequential identifiers make circuits easy to trace, align labels with schematics, and simplify troubleshooting, especially in dense panels with many closely spaced terminal connections.

-

Place labels where they are visible without blocking connections: Proper placement allows technicians to read labels at a glance while maintaining full access to terminals, reducing handling errors and improving safety during installation and servicing.

-

Maintain updated schematics and label records: Keeping documentation synchronized with panel labels ensures accuracy after changes or repairs, supporting efficient maintenance, compliance checks, and reliable long-term system management.

Correct technique makes labels practical, not just compliant.

Need durable labels for harsh electrical environments? Learn how to print on heat shrink tubing for long-lasting, compliant wire identification in this detailed, easy-to-follow guide.

What Types of Terminal Block Labeling Systems Can You Use?

Terminal block labeling systems vary depending on how often labels change, the environment, and the level of customization required. Selecting the right system helps maintain clarity, supports compliance, and ensures terminals remain easy to identify throughout installation, maintenance, and future system updates.

Common terminal block labeling systems include:

1. Pre-Printed Terminal Markers

Pre-printed markers are ideal for standardized numbering schemes and large-scale installations. They provide fast, consistent identification and are commonly used in control panels where terminal numbering follows a predictable sequence.

2. Printable Terminal Strip Labels

Printable terminal strip labels allow custom text, symbols, and numbering. They are especially useful for complex circuits or unique applications where standard markers do not provide enough flexibility.

3. Clip-On or Snap-In Label Holders

These holders are designed for modular terminal blocks and make label replacement simple. They are well-suited for systems that require frequent updates or reconfiguration over time.

4. Adhesive Labels and Wrap-Around Markers

Adhesive and wrap-around labels offer flexibility for retrofits and irregular layouts. They can be applied to existing wiring and terminals where other labeling options are not practical.

5. Engraved or Laser-Etched Tags

Engraved or laser-etched tags provide permanent identification in harsh environments. They are best suited for applications where labels must withstand extreme conditions and remain readable for long periods.

Choosing the right labeling system improves clarity, reduces errors, and increases overall efficiency.

How Do You Maintain and Update Terminal Block Labels?

Terminal block labeling is an ongoing process that requires regular attention to remain accurate and effective. As electrical systems change over time, labels must be reviewed and updated to ensure they continue to support safe operation, maintenance, and compliance.

Best practices for maintaining and updating labels include:

-

Inspect labels regularly for fading, damage, or reduced readability: Routine inspections help catch worn or illegible labels early, ensuring critical information stays visible and preventing confusion or errors during troubleshooting, maintenance, or safety checks.

-

Update labels immediately after rewiring, expansions, or system modifications: Prompt updates keep labels aligned with actual wiring, reducing the risk of misidentification, incorrect connections, and delays during inspections or future servicing.

-

Maintain digital records or label databases: Digital documentation supports traceability, simplifies audits, and ensures technicians can quickly verify labeling details against schematics, even when working across multiple panels or locations.

-

Use replaceable or modular labels: Modular labeling systems allow fast updates without disconnecting wires, minimizing downtime and reducing the chance of accidental damage during changes or upgrades.

-

Follow standardized labeling procedures: Consistent processes ensure uniform labeling across panels and projects, making systems easier to understand, maintain, and safely service by different technicians over time.

Ongoing maintenance ensures terminal block labeling remains accurate as systems evolve.

What Are the Common Pitfalls in Terminal Block Labeling, and How to Avoid Them?

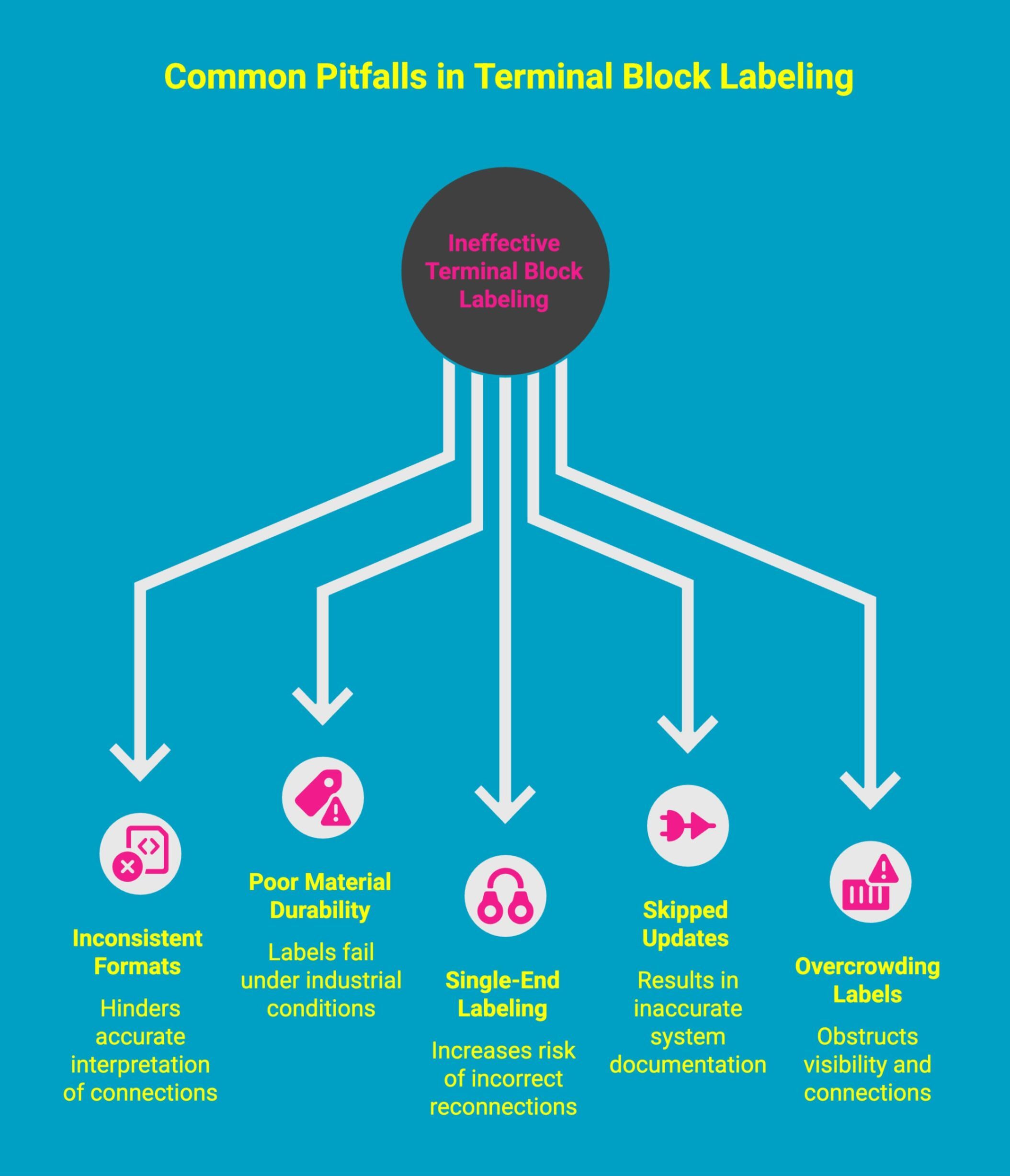

Terminal block labeling issues often result from rushed decisions, inconsistent standards, or a lack of long-term planning. These problems reduce visibility, increase the likelihood of wiring errors, and make maintenance and inspections more difficult over time.

The most common pitfalls include:

1. Using Inconsistent or Unreadable Formats

When labels use different fonts, sizes, colors, or numbering systems, technicians struggle to interpret terminal connections accurately. To avoid this issue, organizations should establish a single labeling standard and apply it consistently across all panels, schematics, and installations.

2. Applying Labels That Fail Under Heat or Chemicals

Labels not designed for industrial conditions may fade, peel, or smear when exposed to heat, vibration, oils, or chemicals. To avoid this problem, always select label materials specifically rated for the environmental conditions of the electrical enclosure.

3. Labeling Only One End of Connected Wires

Labeling only one termination point creates confusion during troubleshooting and increases the risk of incorrect reconnections. To avoid this, both ends of every wire should be clearly labeled to maintain full circuit traceability.

4. Skipping Updates After System Modifications

Failing to update labels after rewiring or equipment changes results in inaccurate system documentation. To avoid this, labeling updates should be treated as a required step whenever electrical modifications or upgrades are completed.

5. Overcrowding Labels and Blocking Visibility

Placing too many labels or excessive text around terminals can obstruct visibility and connections. To avoid overcrowding, use concise identifiers, appropriate spacing, and label holders designed to maintain clear sightlines.

Avoiding these pitfalls improves safety, simplifies maintenance, and supports long-term electrical system reliability.

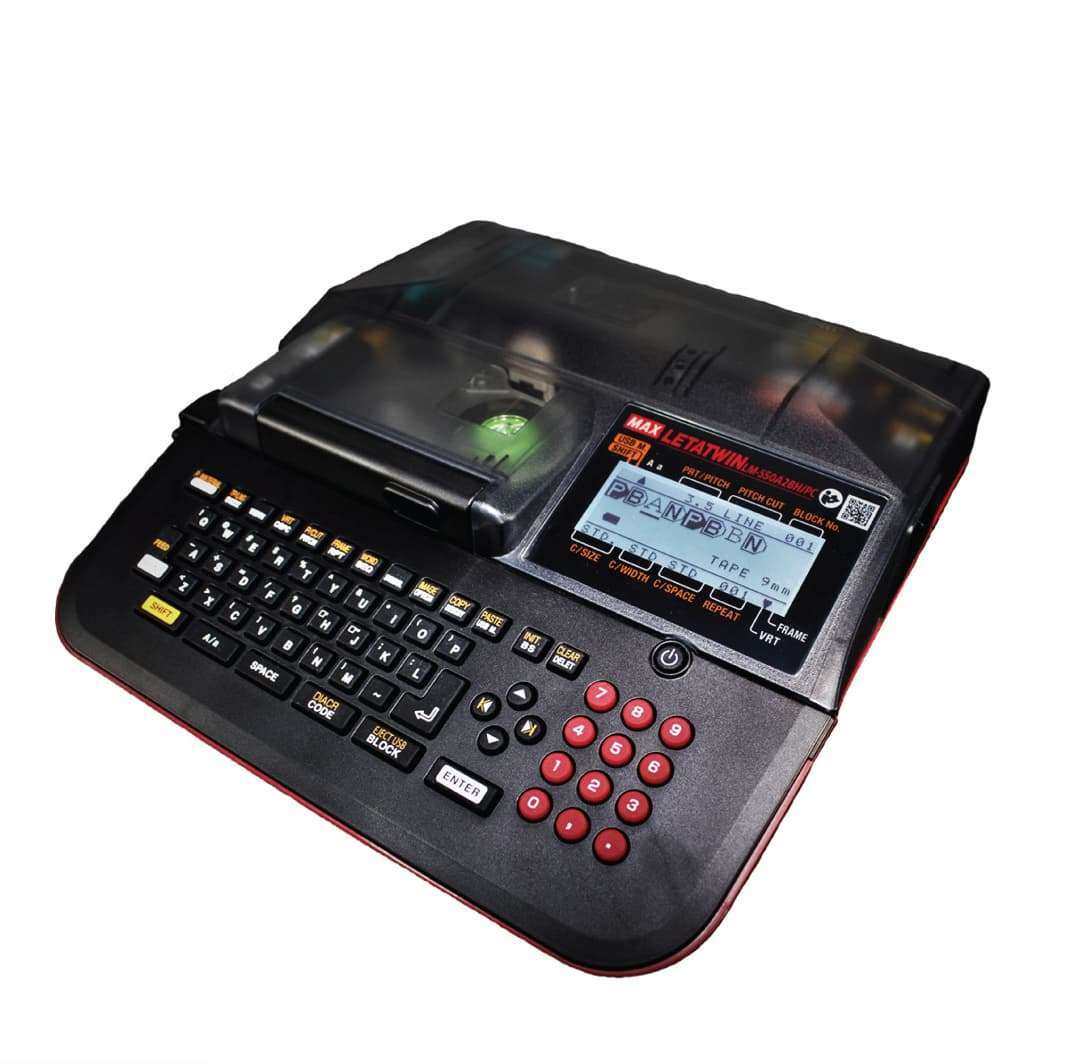

How Does the MAX LETATWIN LM-550A3BH Improve Terminal Block Labeling Standards?

The MAX LETATWIN LM-550A3BH is designed for precise electrical identification, making it well-suited for terminal block labeling. It supports clear, consistent markers that align with industrial standards while offering durability for demanding environments.

Its ability to produce professional, easy-to-read labels helps teams maintain accuracy, consistency, and compliance across complex electrical assemblies.

DuraFast Label Company makes choosing this solution simple by offering expertly curated printer collections, clear guidance, and reliable support, so you can upgrade from outdated equipment and produce professional, compliant labels without extra effort.

Explore DuraFast Label’s printer collection today and find the right labeling solution for your application. Contact us for more information!

Conclusion

Terminal block labeling standards play a critical role in electrical safety, system clarity, and long-term reliability. By following recognized standards, using durable labeling methods, and maintaining consistent identification practices, organizations can reduce errors, simplify maintenance, and ensure electrical systems remain safe and serviceable over time.

Frequently Asked Questions

How do I choose the best type of terminal block label or marker for my application?

Choose a terminal block label based on environment, permanence, space, and change frequency. Harsh settings need durable materials, while tight electrical wiring benefits from slim, replaceable markers that allow updates without disconnecting conductors during routine maintenance or upgrades.

What are the main types of terminal block labels available, and how do they differ?

Common terminal block labels include pre-printed markers, printable strips, clip-on holders, adhesive labels, and engraved tags. They vary by flexibility, durability, customization, and suitability for temporary or permanent identification within a control panel power supply and industrial systems.

What labeling standards or best practices should I follow for terminal blocks?

Follow IEC numbering, UL or CSA safety guidance, and manufacturer instructions. Best practices for DIN rail terminal blocks include consistent formatting, logical placement, durable materials, and keeping identifiers aligned with schematics, drawings, and documentation throughout the panel lifecycle.

Are there printable templates or software tools for designing terminal block labels?

Many industrial label printers provide software with templates supporting spacing, numbering, and formatting. These tools simplify designing custom terminal block labels, helping users generate consistent, professional results that align precisely with block dimensions and installation standards and requirements.

How are terminal blocks numbered?

Terminal blocks are usually numbered sequentially, left to right or top to bottom. Consistent labeling terminal blocks ensures identifiers match schematics, simplifies troubleshooting, reduces wiring errors, and supports safe installation, inspection, and future maintenance across electrical panel systems.

Do terminal blocks need to be UL-listed?

Terminal blocks in UL-certified assemblies generally must be UL-listed or recognized. Using approved components and clear marking labels for terminal blocks helps ensure compliance, safety, and performance within regulated electrical systems and inspected industrial control panels installations.

What should you check before choosing a terminal block?

Before choosing a terminal block, verify current rating, voltage rating, wire size compatibility, mounting style, environment, and certifications. Reviewing these factors together ensures the component performs safely, reliably, and consistently within the intended electrical application and system requirements.

Is blending various categories of terminal blocks within a single application permissible?

Different terminal block categories may be combined if they are electrically compatible, correctly rated, and well identified. Mixing types is acceptable when documentation is clear, spacing is maintained, and maintenance personnel can easily distinguish circuits during installation tasks.

Is it necessary to perform routine maintenance on terminal blocks?

Routine maintenance of terminal blocks is important for safety and reliability. Periodic inspections help detect loose connections, corrosion, overheating, or damaged identifiers early, reducing downtime and preventing faults within control panels and distribution systems during normal operating conditions.

What makes a terminal block different from a wire nut?

A terminal block creates organized, reusable connection points with traceability and clear identification. In contrast, a wire nut simply splices conductors together, offering minimal structure, no labeling, and limited support for troubleshooting or future system modifications and changes.

Where can I buy terminal block marking labels online and print custom options affordably?

Terminal block marking labels are available through industrial suppliers and online marketplaces. Affordable custom printing options include desktop label printers, compatible tapes, and supplier-provided printing services, allowing cost-effective customization without outsourcing large volumes or purchasing expensive pre-printed sets.