Coated Side In (CSI) vs Coated Side Out (CSO) Thermal Transfer Ribbons

Posted by BK on 9th Sep 2019

When buying thermal transfer ribbons for your thermal printer, you’ll encounter the terms CSI and CSO, which stand for Coated Side In and Coated Side Out. What do these terms mean and why are they important?

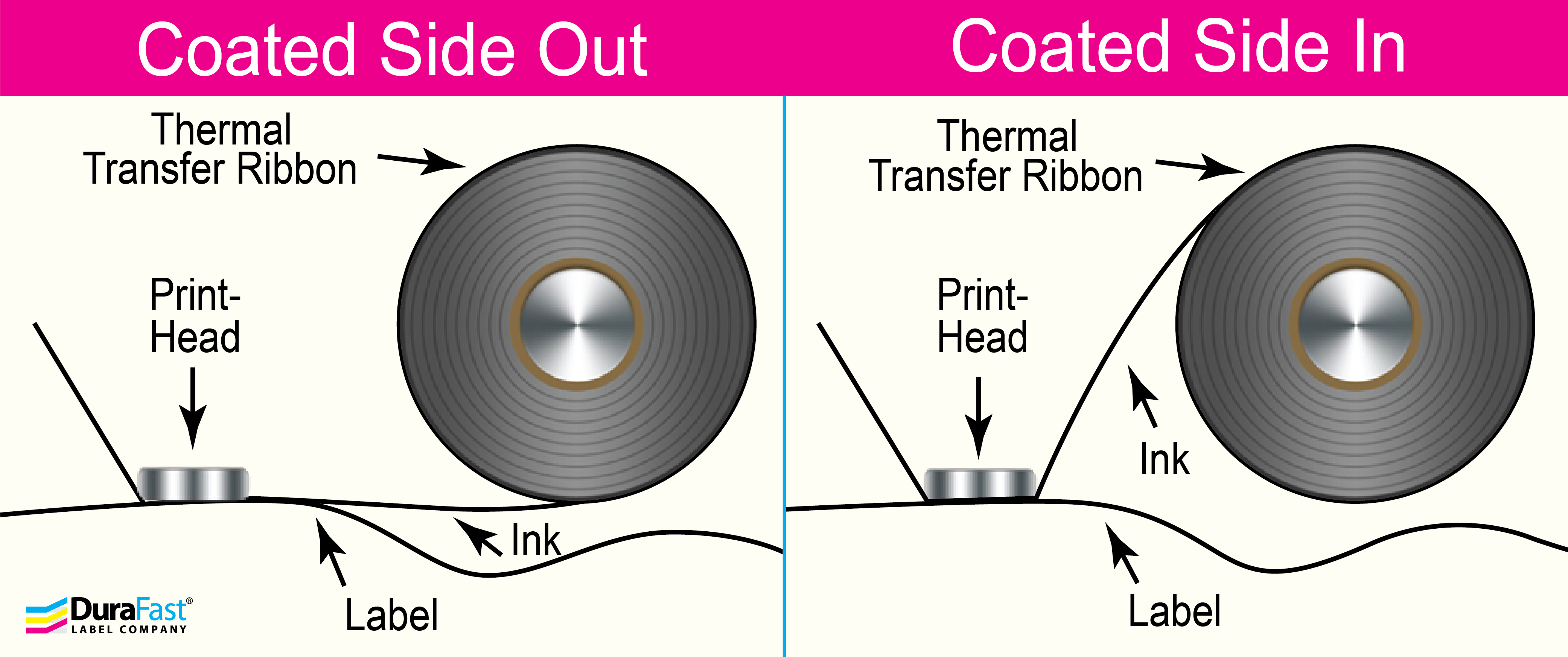

Thermal transfer ribbons are made from a base material that’s coated with ink and then wound onto a core. The ribbon can be wound one of two ways, with the ink coating on the inside or with the ink coating on the outside. Think of how a roll of tape is wound. The sticky side is wound inside. That’s comparable to a coated side in thermal transfer ribbon.

Most thermal transfer printer models take one or the other, though a few will work with both. The position of the ink on the ribbon affects how the ribbon roll is placed within the printer. The ink must face the substrate so it will be transferred once heated with the printhead. Thus, a CSI ribbon will unroll from the top while a CSO ribbon will unroll from the bottom. It’s important to know if your printer takes CSI or CSO ribbons so that you purchase the right ribbon type for your printer.

Thermal Printer Models that Take CSI Ribbons

Datamax and SATO thermal printers typically use CSI ribbons. For example, the Datamax E-4204B, Datamax E-4205A, Datamax H-4212, Datamax H-4606X, Datamax I-4212e, Datamax p1725, Sato CL408e, Sato GT408e, Sato LM408e, and Sato X-2300ZE are just a few of the dozens of Datamax and Sato thermal printers that take CSI ribbons.

Thermal Printer Models that Take CSO Ribbons

Zebra thermal transfer printers use CSO ribbons. Below are a few examples of Zebra thermal printer models that use CSO ribbons:

|

|

|

Thermal Ribbon Materials

In addition to knowing the difference between CSO and CSI thermal ribbons, it’s also important to understand the different thermal ribbon coating types which are:

- Wax Ribbons (inexpensive, general purpose ribbons) — Also called full wax or resin-enhanced wax ribbons, wax thermal transfer ribbons are the most economical choice. They have the highest percentage of wax and the lowest melt points. A small amount of resin is added to the wax to add extra durability. Because of their full wax composition, wax ribbons have a lower melting temperature, which results in a lighter print. These general purpose ribbons are suitable for use with most coated and uncoated paper materials and some low-end synthetics. Wax ribbons are commonly used for printing retail, warehouse, and shipping labels and are perfect for short-term use.

- Wax-Resin Ribbons (increased durability) — Wax-resin ribbons have a blend of wax and resin and can be used with synthetic label materials such as polyester or polypropylene. The wax-resin composition increases durability, providing resistance to water, abrasions, and, when used with appropriate synthetic label stock, some chemicals. Wax-resin ribbons are commonly used for printing barcodes, pharmaceutical labels, and shipping labels. Wax-resin ribbons print well on paper and synthetic materials. If you need to print weatherproof labels or labels likely to encounter moisture or scratches, wax-resin ribbons are a great choice.

- Resin Ribbons (most durable ribbons) — Full resin ribbons feature a pure resin-based ink. The resin melts at a higher temperature than wax and completely dissolves into the label material upon printing, resulting in extremely durable labels, barcodes, and tags. As such, these ribbons are commonly used for chemicals, automotive, and healthcare applications along with applications where moisture, sunlight, water, chemicals, machinery, extreme temperature changes, abrasions, UV light, and other environmental conditions are likely. Resin ribbons are intended to be used on synthetic and high-end films.

Free Ribbon Sample Rolls Available

There’s a lot to consider when choosing a ribbon for your thermal label printer from CSI vs CSO to wax vs resin formulations. To ensure that the ribbon works with your printer and is suitable for the application and labels you will be using, request a free sample roll for testing purposes. We’ll mail the ribbon sample to the address you provide so that you can test it out before you buy. Request ribbon samples here.

If you’re not sure which type of ribbon your printer requires, contact us and we’ll be glad to help.